Dust-Free & Quality

Certified Excellence in Custom Manufacturing

Premium’s certifications in ISO9001, IATF16949, and ISO13485 are more than just seals of approval; they are the foundation of our manufacturing excellence

- Selecting the top-quality materials for durable, high-performance components.

- Highly trained team dedicated to maintaining stringent manufacturing standards.

- Each product rigorously inspected to meet our exacting certification standards.

- IATF16949-certified for advanced automotive quality management and improvement.

- Producing medical devices compliant with ISO13485, ensuring safety and quality.

Our Trustworthy Raw Material Suppliers

BASF

A leading global supplier known for a wide range of plastic materials

DuPont

Offers specialized polymers suitable for various injection molding applications

Alcoa Corporation

A major producer of aluminum, which is widely used in CNC machining

ArcelorMittal

The world’s leading steel and mining company, providing various steel grades.

Our Product Testing Protocol

In-Depth Testing Protocols: Our quality control includes a series of stringent tests, tailored to each manufacturing discipline

UV resistance test

Expose the injection-molded products to UV radiation and observe the changes in color, surface quality, strength, etc. to evaluate the UV resistance of the products

Impact resistance test:

Impact test on injection molded products by impact testing machine, observe the destruction of the product under the impact load, in order to assess the impact resistance of the product.

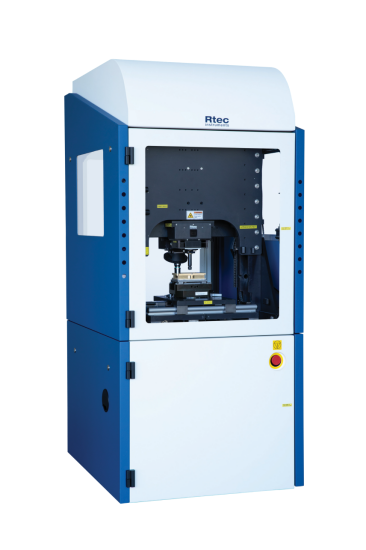

Fatigue testing

Fatigue testing of stamped products by fatigue testing machine for cyclic loading, bending, torsion and other fatigue tests to evaluate the fatigue resistance of the products

Corrosion resistance test

Stamped products are put into contact with different chemicals to observe the chemical resistance performance of the products, including strong acid, strong alkali, solvents and so on.

Surface roughness test

Observe the roughness of the surface of CNC machined products by using a surface roughness meter or microscope to assess the surface quality of the products

Scratch hardness test

Evaluate the surface treatment quality and hardness by scratching the product surface with a hardness tester. Commonly used test methods include Lackey hardness test, Rockwell hardness test, etc.

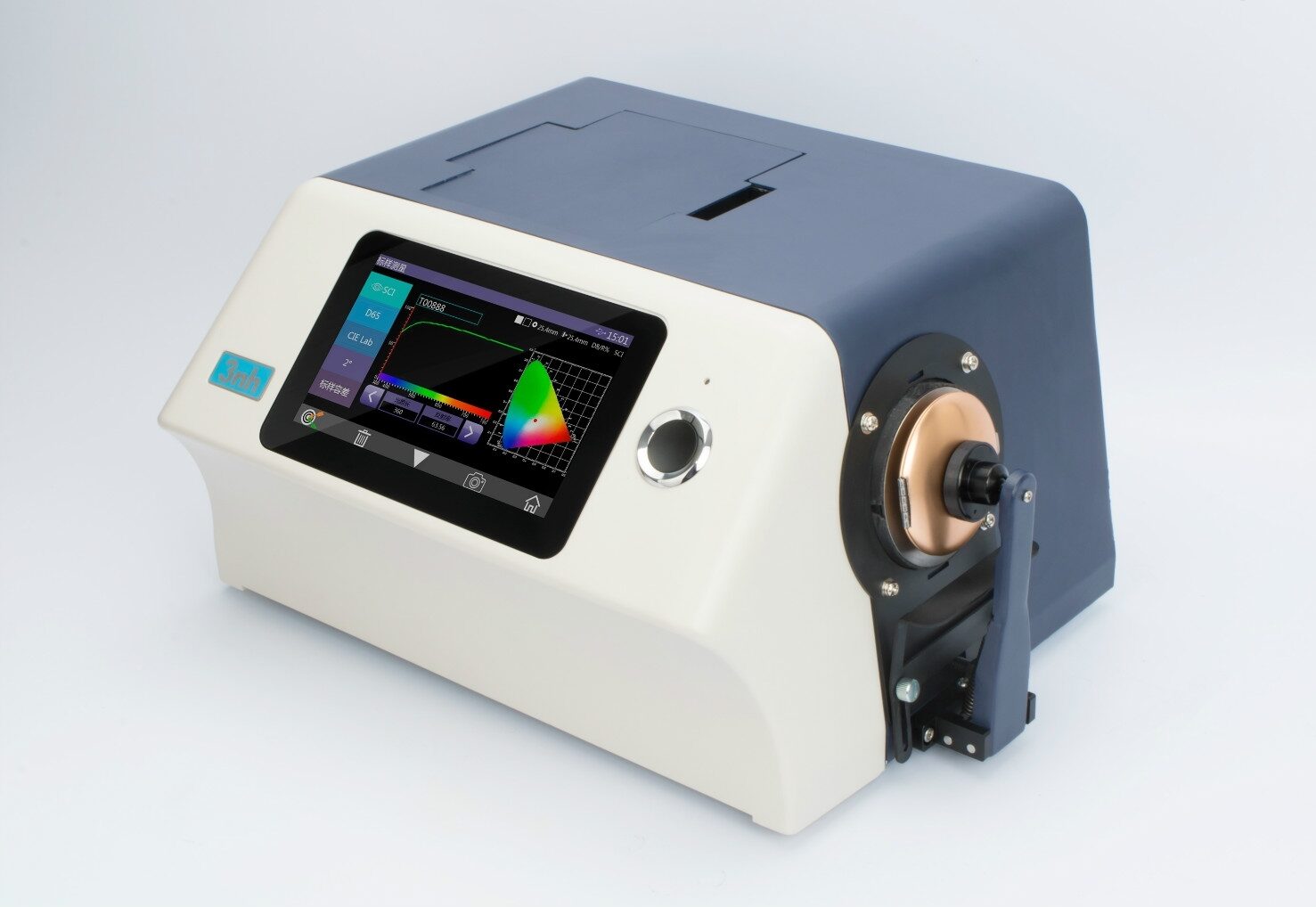

Color Difference Test

Measure the color of the product surface with an instrument to assess the uniformity and consistency of the surface treatment. Commonly used test methods include Color Difference Meter Test, Visual Comparison, etc.

Certifications

ISO9001

ISO14001

IATF16949

ISO13485