Your One-Stop Manufacturing Factory From Customized Plastic To Metal Components

Elevate your project from concept to reality with Premium, experience the seamless transformation of your designs into high-quality plastic and metal parts, fitting perfectly within your timeline and budget,Start optimizing your project costs effortlessly today !

Meet the Right Services

Our Manufacturing Services

Access high-quality, cost-effective injection molding and bridging molds swiftly with Premium. Utilize our free formability consultation to fast-track design and production, minimizing both time and expense. Choose from over 100 materials, assured by rapid, automated quality checks.

Accelerate your projects with Premium’s rapid, 5-axis CNC Machining, achieving ultra-precise tolerances down to ±0.001 in. (0.020mm). Fast-track production without compromising on quality or precision, complemented by a versatile range of finishes.

Mastering Reaction Injection Molding, Premium excels in crafting large, cost-effective parts with 3-30mm thickness, ideal for medical and automotive shells. Expect precision, customized finishes, and insert molding excellence.

Premium excels in crafting large, perfectly flat sheet metal parts. Opt for a wide range of materials and surface treatments, ensuring each piece meets your exacting standards with no deformation.

Case Study:

Beauty Instrument Handle Production

Background

A leading beauty instrument manufacturer approached Premium to create the complete handle for a new beauty device. This project required manufacturing both metal and plastic parts, with an emphasis on seamless integration and aesthetic appeal.

Challenge

The client needed a manufacturing partner who could not only produce high-quality components,but also actively contribute to the design and prototyping phases, addressing issues like assembly inconsistencies and color chromatic aberration.

Solution

- Design Optimization: Premium refined the client’s drawings for enhanced manufacturability, advising on materials and design elements.

- Prototype Validation: Created prototypes to test design efficacy and ergonomic suitability.

- Material Selection & Color Matching: Selected high-grade materials and implemented a strict color matching process.

- Precision Manufacturing: Utilized 5-axis CNC machining and injection molding for precision production.

- Quality Control: Conducted comprehensive quality checks and assembly testing to ensure product integrity.

Company Information

Precision Manufacturing, Customized Solutions

At Premium, we specialize in advanced manufacturing, offering expertise in injection molding, mold processing, CNC machining,Reaction injection molding and sheet metal fabrication. Our facilities are geared towards transforming your intricate designs into high-quality, custom plastic and metal parts. Committed to precision and excellence, Premium is your ideal partner for reliable, efficient manufacturing solutions that bring your innovative projects to life.

ISO9001

ISO14001

IATF16949

ISO13485

-scaled.jpg)

Technical Support

Design and Engineering Support

Discover Premium’s Design and Engineering Brilliance:Where your vision becomes a market reality. We blend artistic ideas with pragmatic engineering using advanced CAD and 3D modeling, ensuring flawless functionality. Our Design for Manufacturing (DFM) approach aligns your concepts with market needs, transforming them from ideas to market sensations, efficiently and effectively.

Most Important

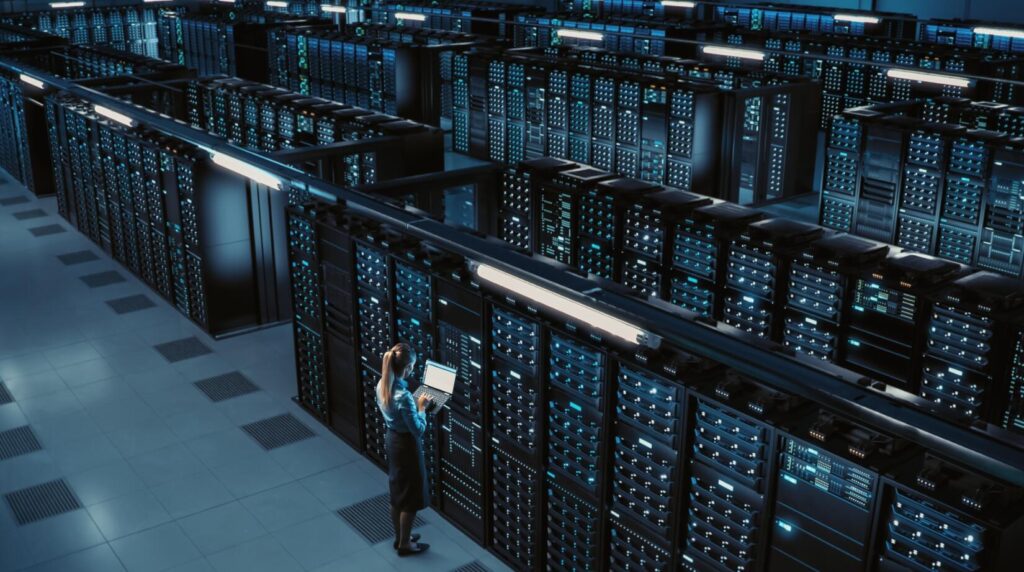

Quality Assurance

-1-1024x683.jpg)

Industries Catered

With over a decade of expertise, Premium Rapid and Mold excels as a key provider of custom injection molding,sheet metal fabrication and CNC machining services, offering tailored solutions for diverse industries globally. Our one-stop service, from prototyping to mass production, ensures quality and efficiency for our clients

The automotive industry demands parts that combine strength, precision, and durability. Premium’s advanced injection molding and CNC machining technologies produce components crucial for vehicle safety and performance. From engine parts to interior assemblies, we deliver solutions that align with the automotive sector’s dynamic and stringent requirements, tailored to each client’s specifications.

In the electronics industry, where precision and miniaturization are crucial, Premium’s injection molding and sheet metal fabrication capabilities provide essential components. We fabricate parts like enclosures and chassis that offer durability and effective heat dissipation, ensuring reliability in consumer electronics and advanced industrial equipment.

The medical industry requires components that meet the highest standards of safety and hygiene. Premium excels in producing sterilizable, biocompatible parts essential for medical devices. Utilizing state-of-the-art injection molding and CNC machining, we craft everything from surgical instruments to diagnostic devices, adhering to the stringent specifications of the healthcare sector.

Aerospace applications demand materials that are both lightweight and exceptionally strong. Premium’s expertise in molding and machining produces aerospace components that withstand extreme conditions while enhancing safety and efficiency. We provide parts that are integral to the structure and shell of aircraft and spacecraft, customized to each project’s unique aerospace requirements.

In telecom, Premium’s Plastic injection molding and sheet metal fabrication services provide high-quality, durable components for communication systems. From sturdy antenna structures to precision parts for base stations, our tailored solutions ensure reliability and longevity in the rapidly evolving telecommunications infrastructure.

Industrial machinery requires robust and precise components, a specialty of Premium’s CNC Machining and sheet metal fabrication services. We create parts that withstand the rigors of industrial environments, contributing to the machinery’s performance and durability. Our custom solutions support a wide range of machinery used in manufacturing and processing sectors.

Our Testimonials

Real Reviews from Real Customers

In our quest for specific sheet metal and high-gloss plastic parts, Premium was a game-changer. They nailed the infrared transmittance and powder coating we needed. It’s rare to find a supplier who truly gets the nuances of our product needs. Partnering with Premium has been a key factor in the quality and appeal of our heaters.

Dominik

Company Head

For our beauty device handle, finding a supplier who could handle everything from silicone to stainless steel with precision was challenging. Premium delivered beyond expectations – the parts fit perfectly, the plastic is tough enough to withstand drops, and the metal finishes are top-notch. They’ve elevated our product’s quality and durability, making them an invaluable part of our supply chain.

Sara

Company Purchaser

Designing a unique beer tower for Budwei, we needed parts that were not only food-grade and transparent but also viable for mass production without breaking the bank. Premium struck the perfect balance, bringing our design to life while keeping costs in check. Their expertise in material selection and manufacturing has been crucial to our project’s success.

Jonathan

Product Design Engineer

FAQs About Premium Rapid & Mold 's Services

We’ve compiled the most frequently asked questions about our one stop manufacturing services for your convenience. However, should you have any additional questions, please don’t hesitate to contact us.

At Premium, our one-stop service streamlines your project from start to finish. Enjoy seamless transitions from design for manufacturability (DFM) to prototyping, mold making, and small to medium volume production. This cohesive approach not only saves you time and resources but also ensures consistent quality and communication throughout your project's lifecycle.

Yes, customization is our forte. Whether it's a single piece or a batch up to 10,000 pieces, we specialize in custom injection molding,sheet metal fabrication and CNC machining to meet your specific requirements. Our flexible mold design and processing solutions are crafted to align perfectly with your unique project demands.

Our team is equipped to support you during the product design stage. We provide valuable insights for DFM, helping you understand various material types and optimizing your design for manufacturability, thereby saving you time and money.

We offer a variety of surface treatments including painting, plating, anodizing, and powder coating. These options not only improve the appearance of your parts but also enhance their durability and performance.

Yes, we provide part assembly services to add value to your production process. This service complements our manufacturing capabilities, ensuring a complete solution from part fabrication to assembly, tailored to your project needs.

Premium upholds the highest standards, reflected in our certifications. These include ISO 9001,IATF:16949 and ISO13485 ensuring our processes meet international quality standards.

Prompt Notification: We encourage you to notify us as soon as you detect any defects. Our customer service team is always ready to assist you.

Assessment & Verification: Upon receiving your notification, we initiate a quick assessment to verify the issue. This may involve requesting photos of the defect, or in some cases, returning the part for inspection.

Swift Resolution: Based on the assessment, we offer appropriate solutions which could include repairing the defective part, manufacturing a replacement, or in certain circumstances, issuing a credit or refund.

Root Cause Analysis: To prevent future occurrences, we conduct a thorough analysis to identify the root cause of the defect and take corrective actions in our manufacturing processes.

Continuous Support: Throughout the process, our team maintains open communication with you, providing regular updates and ensuring that your concerns are addressed promptly and satisfactorily.

Lead times vary based on project complexity and volume. However, we pride ourselves on efficient processes, typically offering faster turnarounds than industry averages, especially for small to medium-sized orders.

Our payment terms are designed to be client-friendly, usually involving an initial deposit with the balance payable upon project completion. We strive for transparency and flexibility to accommodate your financial planning.

Our manufacturing solutions cater to a wide range of industries including automotive, medical, electronics, and consumer products. We adapt our expertise to meet the specific requirements of each sector.

Yes, we offer comprehensive technical support and guidance right from the onset of your project. Our team of experts is ready to assist with any technical queries or challenges, ensuring a smooth start to your project.

Quality is paramount at Premium. We implement rigorous quality control processes at every stage of production, from initial design to final output. Our adherence to ISO 9001 standards is a testament to our dedication to delivering superior quality parts.

We pride ourselves on flexibility, including in our MOQ policies. We accept orders as small as a single prototype and scale up to thousands of units, offering solutions that are tailored to your project's specific needs and scale.

Timely delivery is a cornerstone of our service. We achieve this through meticulous project planning, regular progress monitoring, and proactive communication. Our experienced project managers work diligently to anticipate and mitigate any delays, ensuring your project stays on schedule.

Contact Us

Get Started With Premium Rapid & Mold Now!

We always want to make sure that our customers are getting the best deal, so let us know what you’re interested in and we’ll get back with a quote!