Even the best project can go sideways if the quality isn’t there. Imagine getting a batch of parts that don’t fit together right. It’s frustrating, right? There’s a reason quality control (QC) is so important in sheet metal fabrication. If you don’t have good QC processes in place, you’re going to make mistakes. Those mistakes will cost you money, create safety issues, and make your customers mad.

You can’t skip quality control in sheet metal fabrication. QC ensures your parts are accurate, made from the right material, consistent, and meet industry standards. These are all important things if you want to make parts that fit, reduce mistakes, and keep your customers happy. QC also keeps you from screwing up and having delays, spending more money than you should, or having parts that don’t work. You have to do QC if you want to make good parts.

To make sure you get a good part every time, you have to do QC at every step of the process. From picking the right material to doing a final inspection, QC is the backbone of making parts and making sure you don’t mess up. By making sure you don’t have mistakes and you’re consistent, QC not only keeps your parts good but saves you time and money in the long run. In this article, I’m going to tell you why you have to do QC in sheet metal fabrication and why it helps you and your customer.

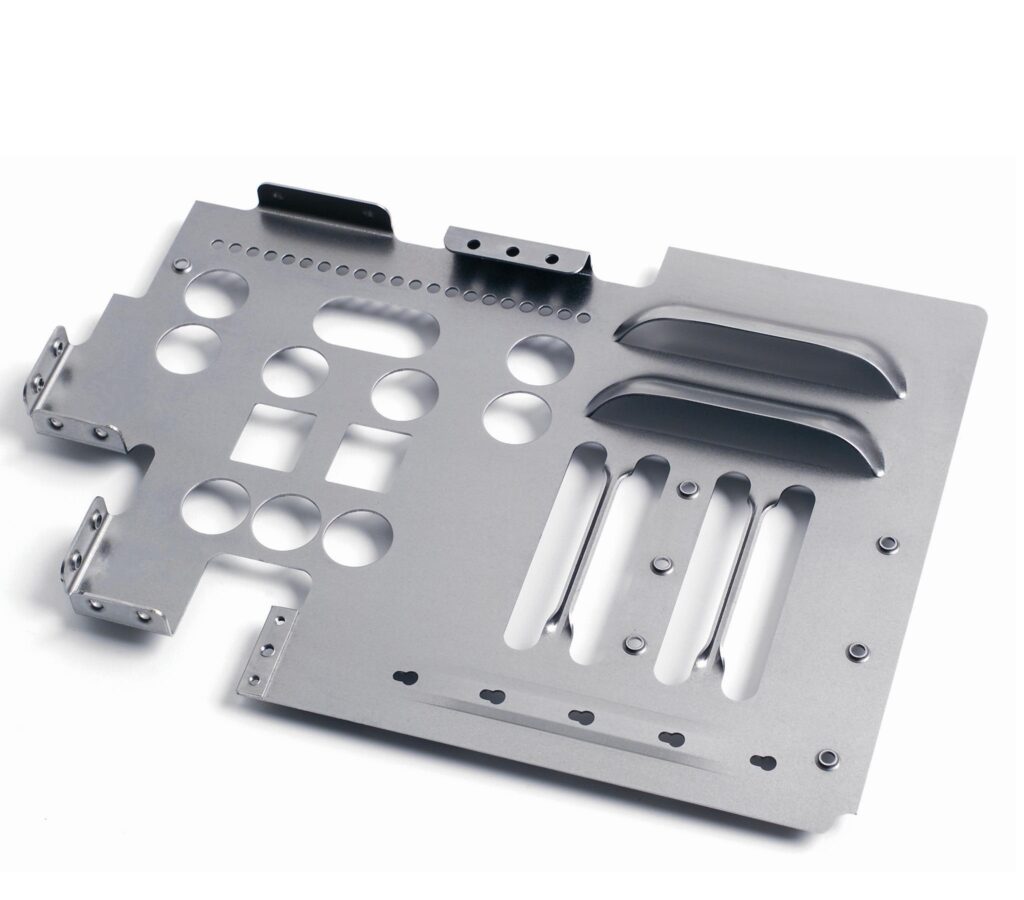

Why Is Precision So Critical in Complex Designs?

Precision is the key to making good sheet metal parts. In industries like aerospace, automotive, and medical, if your part doesn’t fit right, you can have big problems. Your part might not work right, or it might even be dangerous. QC makes sure every part you make fits the way it’s supposed to by checking it and using machines like CNC machines and lasers to cut it. By keeping the tolerances tight, QC makes sure your part works right and is safe. This is important in industries where your part has to work right and fit right all the time.

How Does Material Integrity Impact Quality?

Material integrity is important to make sure your sheet metal part works right in the application it’s supposed to be used. If you have bad material, your part can corrode, change shape, or break, especially in industries like aerospace and medical. QC is important because it makes sure your material is good before you make a part. This means you check the material for defects and make sure you’re using the right material for the job. This keeps you from having problems later where your part doesn’t work right or is dangerous.

Why Is It Important to Make Sure Every Part You Make Is the Same?

You need to be consistent in sheet metal fabrication so that every part you make, no matter how many you make, is the same. If you make parts and the quality is different every time you make them, you’ll have issues when you put them together, you’ll spend more money, and your customers will be mad. QC processes, like statistical process control (SPC), help you be consistent by watching what you do and making changes as you go. This way, every part you make, whether you make one part or a million parts, meets the specifications you need it to, and you can rely on it and trust that it’s good.

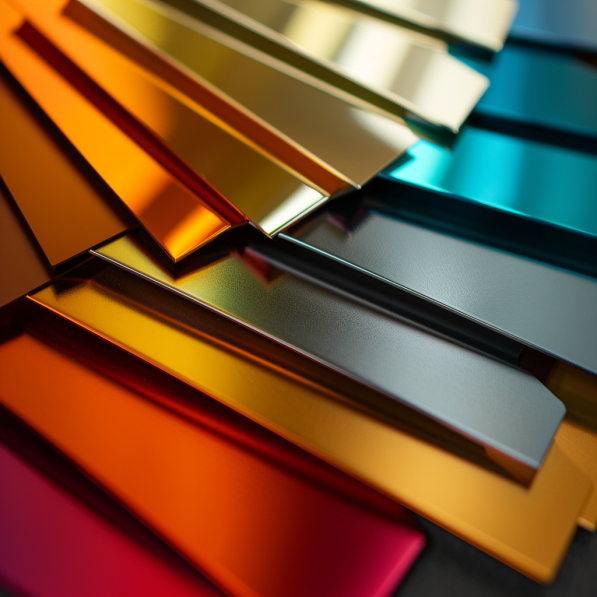

Why Do Surface Finish and Treatment Matter?

Surface finish and treatment are important because they make your parts look good and work good. If your finish is bad, your part can corrode, wear out, and not look good, which can cause your product to wear out and your customer to be mad. QC is important because it makes sure you finish your parts and treat them correctly. By checking and making sure your parts look the way they’re supposed to, QC makes sure your parts look good and work good where you put them.

How Does QC Keep You from Having Assembly and Fit Problems?

When your parts don’t fit together right, you have assembly and fit problems that can cause things to break and cost you more money. QC is important because it makes sure you make your parts the right way. This means you check and measure your parts to make sure they are the right size and fit the right way. QC also means you put your parts together and make sure they work the right way. By making sure your parts fit and work the right way, QC keeps you from having to redo things and makes your parts better.

How Does QC Keep You from Making Mistakes and Throwing Parts Away?

Mistakes and throwing parts away cost you money in sheet metal fabrication because you have to buy more material, pay someone to fix your mistakes, and wait longer to get your parts. QC keeps you from having these problems by looking at and checking your parts as you make them. By finding mistakes early, QC keeps you from making bad parts and throwing them away, making sure you only make good parts and give them to your customer. This saves you money and makes you more efficient and keeps your parts good.

Why Is Client Trust and Long-term Relationships Important?

Your customers want you to make good parts for them and send them to them on time and without spending a lot of money. QC helps you do this by making sure every part you make is what your customer wants. By making sure you don’t make mistakes and you’re reliable, QC helps you build a good relationship with your customers. This is important when you make parts that can’t fail because you want your customers to trust you and come back to you every time they need parts. By being good and reliable, your customers will trust you and want to work with you for a long time.

How Do You Make Sure You Meet the Rules of the Game?

You make sure you meet the rules of the game by following standards like ISO 9001:2015 that tell you how to make good parts. If you make parts for industries like aerospace and medical, you have to follow the rules and make good parts. QC makes sure you do everything right, from picking the right material to checking your parts when you’re done, to meet the standards. By following the rules, you make sure people think you’re good and trust you to make good parts that are safe and work the right way.

How Does Technology Help You Make Better Parts?

Technology helps you make better parts by using machines like CNC machines, lasers, and robots to cut and check your parts. These machines watch what you do, collect data, and let you know if you’re doing things the right way. By using these tools, QC can make sure your parts are good and the same every time you make them. This not only keeps you from making mistakes but helps you make parts faster and better, which makes your customers happy and makes them want to work with you more.

What Is the Importance of Traceability and Documentation in QC?

Writing everything down and knowing where your parts come from is important so you can keep track of what you do and where your parts come from. This is important when you make parts for industries like aerospace and medical. By writing stuff down, you can find problems fast, have someone check you out, and know what you did in the past. Knowing where your parts come from lets you know if something goes wrong, so you can fix it and make things better.

Why Is QC Crucial in Customization and Prototyping?

You have to check every part you make when you make custom parts and prototypes because you make only a few of them, and they have to be the same every time. If you make a mistake, you don’t have many parts to fix it, and you have to make them right the first time. QC makes sure you make every part you make the right way. By checking you out and making sure you do things right, QC keeps you from making mistakes and having to do things over. This makes sure you make good parts and give them to your customer, so they can use them and be happy.

What Happens When You Make Bad Parts and Send Them to Your Customer?

When you make bad parts and send them to your customer, you have problems because they can’t use the parts and you have to send them new ones. This makes you spend more money, makes your customer mad, and makes you look bad. QC keeps you from doing this by checking your parts and making sure they’re good before you send them to your customer. By doing this, QC keeps you from making mistakes, sending bad parts, and looking bad, and makes you look good and makes your customer happy.

Conclusion

Quality control is the cornerstone of successful sheet metal fabrication. It’s what makes sure every part you make is precise, made from the right material, consistent from part to part, and meets all the industry standards. By catching mistakes and making sure everything is right, QC not only makes sure the part you’re making is right but also builds trust with your customer and helps you keep that customer for a long time. In today’s competitive manufacturing environment, you’ve got to have good quality control in place to make sure you’re delivering parts that are better than what the customer expects so you can keep your business growing.