Everyone wants more durable and better-looking products. Anodizing sheet metal might be the perfect solution. It makes your metal parts look better and last longer. Here’s why you should consider anodizing your metal parts.

Anodizing is an electrochemical process that turns your metal surface into a good-looking, long-lasting, corrosion-resistant finish. It’s great for a lot of industries, from automotive to consumer electronics. When you anodize your sheet metal, you make your product last longer and look better.

But why does anodizing work so well? First, it puts a tough oxide layer on your metal surface, protecting it from wear and tear. You can also customize it to give you a wide range of colors, making your product not only last longer, but look great too. Whether you’re in the automotive, aerospace, or electronics industry, anodizing will make your products look a lot better.

What is Anodizing?

Anodizing is a process used to thicken the natural oxide layer on the surface of metal parts. This process involves immersing the metal in an electrolytic solution and passing an electric current through it. The result is a durable, corrosion-resistant surface that can be dyed various colors. Aluminum is the most common material for anodizing, although titanium can also be anodized. Magnesium is typically not anodized due to its high reactivity and the difficulty in achieving consistent results.

Benefits of Anodizing

Enhanced Corrosion Resistance

One of the main advantages of anodizing is its ability to protect metal parts from corrosion. The oxide layer produced during anodizing acts as a barrier, preventing moisture and other corrosive substances from reaching the metal.

Improved Durability and Wear Resistance

Anodized metals are more resistant to wear and tear, making them ideal for high-use applications. This durability ensures that parts maintain their appearance and functionality over time.

Aesthetic Enhancements

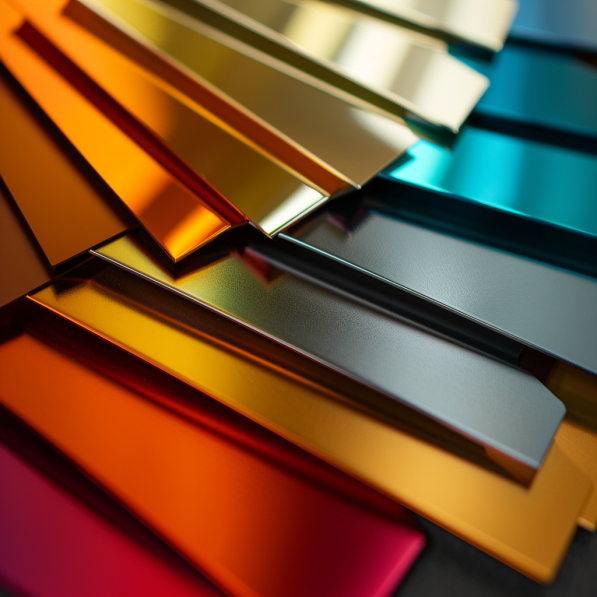

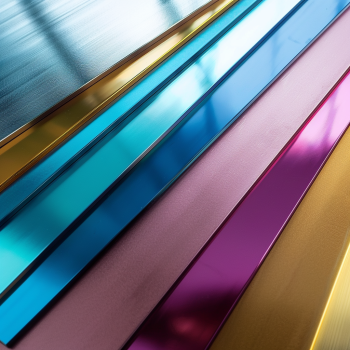

Anodizing offers a wide variety of colors and finishes, allowing you to enhance the visual appeal of metal parts. Whether you want a sleek, modern look or need a specific color to match your brand, anodizing can achieve it.

Electrical Insulation Properties

Anodized surfaces are non-conductive, providing an additional layer of electrical insulation. This property is especially useful in electronic applications where preventing electrical interference is critical.

Anodizing Process Steps

Surface Preparation

Before you anodize, you have to clean and pre-treat the metal to get rid of all the gunk. This makes sure the anodized layer sticks properly to the surface.

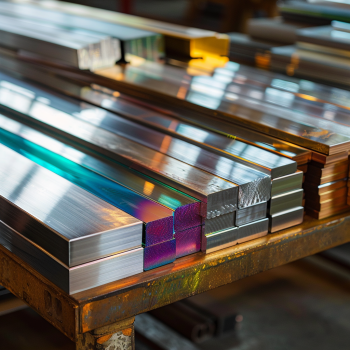

Electrolytic Oxidation

You stick the metal in an electrolyte solution and pass an electric current through it. This is what creates the oxide layer that makes your part look good and last longer.

Coloring

If you want a colored finish, you can add dyes during the anodizing process. The oxide layer soaks up the dye, creating a color that lasts a long time and looks good.

Sealing

The last step is sealing the anodized layer to make it last even longer and protect it from corrosion. You usually do this by sticking the metal in hot water or a sealing solution.

Added Durability in a Variety of Colors

Anodizing offers you the unique ability to have both durability and a wide variety of colors. You can pick from a lot of colors to fit your design needs while also making sure your parts can stand up to the elements. The anodized layer can take a lot of abuse, so if you need something that’s both strong and looks good, anodizing is the way to go.

Materials Available for Anodizing

1.Aluminum: Aluminum is the most common material for anodizing due to its excellent properties. Several types of aluminum alloys are suitable for anodizing, including:

- 6061 Aluminum: This is super versatile, has good mechanical properties, and is easy to anodize. It’s commonly used for structural stuff.

- 6063 Aluminum: This is often used in architectural applications. It has a great finish and is good for fancy shapes.

- 7075 Aluminum: This is a high-strength alloy often used in aerospace applications. It anodizes well but may not look as shiny as other alloys.

- 5005 Aluminum: This is great for stuff that needs to have excellent corrosion resistance. It’s also good if you want your anodized finish to look the same every time. That’s why it’s popular for architectural panels and things that need to look pretty.

2.Titanium: This is often used in medical and aerospace applications because it’s strong and biocompatible.

3.Magnesium: You can anodize magnesium, but people usually don’t because it’s reactive and hard to get a consistent finish. It’s lightweight and used in the automotive and aerospace industries.

4.Zinc: This is good if you need something that’s going to resist corrosion.

5.Nickel: This is used for its hardness and resistance to oxidation.

Things to Keep in Mind with Anodized Parts

Potential Imperfections

Anodizing can show imperfections, so you need to make sure your metal is super clean before you anodize it. If you have any scratches, blemishes, or surface defects before you anodize, they’re going to look even worse after you’re done. Unlike painting or coating, anodizing doesn’t hide imperfections. If you want your part to look good after anodizing, make sure it’s flawless before you start.

Color Finishes May Vary

It’s hard to get the colors to match perfectly with anodizing. The type of metal in the alloy, the thickness of the oxide layer, and the dyeing process all affect the color. It’s important to remember that parts from different batches might not look exactly the same. If you talk to your anodizing service about the color you want, they can help you manage these differences.

Material-Specific Considerations

Not all aluminum alloys look the same after anodizing. For example, parts made from anodized 7075 aluminum don’t look as shiny as parts made from other aluminum alloys. Plus, there’s a bigger difference in appearance between the face and the edge on parts made from 7075 aluminum because it has a lot of zinc in it. Understanding what your metal is made of will help you figure out what the final product will look like.

Non-Conductivity

Anodized surfaces don’t conduct electricity, which can be a problem if you need your part to conduct electricity. This is especially important if you have electronic parts that need to be grounded or connected to other parts. Don’t anodize parts that you need to weld, either. The anodizing will get in the way of the welding process and can rub off, exposing the raw metal underneath.

Dimensional Changes

Type II anodizing adds between 0.0002 inches and 0.0009 inches to each side of your part. That might not sound like a lot, but it’s a big deal if you need your part to fit perfectly. The extra thickness can mess up the fit and function of parts that need to be put together just right.

Durability and Scratch Resistance

Even though it’s tough, anodizing can still get scratched. If you scratch the anodizing, you’ll see the raw material underneath. If you’re in a place where your part will be in constant contact with other stuff or get rubbed a lot, you might need to do something extra to protect the anodizing. If you need your part to be perfect, ask for the harder anodizing types, like Type III, which are better at resisting scratches.

Bend Lines Visibility

You can see the lines from bending through the anodizing. This happens because bending stretches and compresses the metal, and the anodizing doesn’t always go on evenly. If your part has a lot of bends, you need to think about how they’ll look after you anodize them.

Technical Specifications and Standards

Thickness Control

Being able to control the thickness of the anodized layer is crucial if you want to meet industry standards and make sure your parts work right. This is especially important in aerospace and electronics because you need your parts to be super precise to work correctly and last a long time. For example, in the aerospace industry, the thickness of the anodized layer can affect how much aircraft parts weigh and how strong they are.

MIL-A-8625

When you anodize parts to military standard MIL-A-8625, you’re making sure you’re doing it right for defense stuff. This standard tells you how to anodize parts for the military so that they’re tough and work right. If you make parts for the military or defense stuff, you have to follow MIL-A-8625.

Anodizing Types in Detail

Type I (Chromic Acid Anodizing)

Type I anodizing uses chromic acid to make a thin, flexible coating that’s good at resisting corrosion. This type is great for aerospace stuff because you don’t want the parts to change size very much. The thin layer means the parts stay light but also don’t rust.

Type II (Sulfuric Acid Anodizing)

Type II anodizing is the most common kind. It’s a good mix of tough and thick. You can use it for a lot of stuff, like architectural parts and things you buy in stores. You can dye Type II anodizing different colors, so it looks good and works right.

Type III (Hard Coat Anodizing)

Type III anodizing, also called hard coat anodizing, gives you a thick, hard layer that’s great at resisting wear and rust. You use this kind of anodizing for stuff that gets used a lot, like military parts and big machines, because it’s super tough.

Surface Finish Options

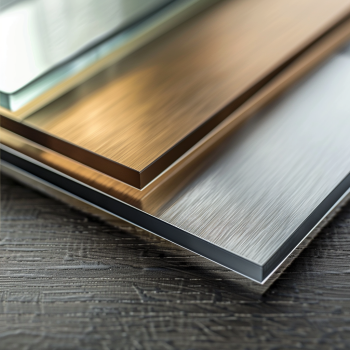

Matte Finish

Bead blasting your metal before anodizing gives you a matte finish. It looks dull and isn’t shiny. This is great for stuff that’s going to be outside or used in cars because it reduces glare.

Glossy Finish

If you polish your metal before you anodize it, you get a glossy finish. This makes your part look shiny and is perfect for stuff that needs to look good, like things you buy or parts in a building.

Brushed Finish

Brushing your metal before you anodize it gives you a brushed finish. This makes your part look like it has lines going down it. It looks good and hides small scratches. This finish is popular for things like kitchen appliances and the electronics you use every day because it looks modern and cool.

Color Uniformity and Customization

Keeping Colors the Same

It’s hard to keep the colors the same between different batches. You need to work with people who know what they’re doing to make sure your colors look right. They need to control the process and check the quality to make sure the colors don’t change.

Custom Colors

You can make all sorts of custom colors with anodizing. This means you can make your parts look the way you want and are different from other people’s parts. Different colors can make your parts stand out and show people that you’re the best.

Post-Anodizing Treatments

Sealing

You have to seal the anodized layer to close up the pores, stop corrosion, and keep the colors looking good. This makes sure your anodized parts last a long time.

Laser Marking

After you anodize parts, you can use a laser to put logos, serial numbers, or other information on them without hurting the anodized layer. This is a good way to make sure people know your stuff is yours.

Industry-Specific Applications

Medical Devices

People use anodizing in medical stuff because it works with your body, doesn’t rust, and can be sterilized. Doctors use anodized aluminum in surgical tools and things they put in your body.

Marine Applications

Anodized aluminum doesn’t rust from saltwater, so it’s good for boat stuff. People use it for hardware and parts on boats that have to be in the ocean.

Outdoor Furniture

The way anodized parts look and how well they last make them perfect for furniture you put outside. They can take the sun, rain, and snow and still look good. Anodizing makes sure your outside stuff looks great and lasts a long time.

More Than Just Anodizing: Our Full Range of Services

At Premium Rapid & Mold, we do more than just anodizing. Here’s what we offer to help you with all your fabrication needs:

Laser, Water Jet, and CNC Cutting Services

We do custom laser cutting, waterjet cutting, and CNC routing to make sure your parts are perfect. Our machines can handle complicated designs and lots of different materials. We can make your parts in 2-4 days, which is pretty fast.

Bending & Forming

We have machines that can bend your parts in different ways. We can bend 11 different materials and make your parts in 1-2 days. This lets you make parts with shapes and bends that are just for you.

Tapping and Countersinking Services

We can put threads in your parts or make holes that are just the right size for hardware. We can do this on 12 materials to make sure your parts are perfect. This is great for parts that need holes that are just the right size for screws or for parts that need to sit flat.

Hardware Insertion

We have a bunch of different nuts, studs, and standoffs that we can press into your parts. We can do this on 8 materials and make your parts in 1-3 days. This makes your parts work better and makes them ready to go as soon as you get them.

Plating

We can cover your parts with zinc or nickel to keep them from rusting and make them stronger. We can do this on 3 materials in 7-10 days. Plating makes your parts last longer and work better, even in places that are really hard on parts.

Powder Coating

We can paint your parts with powder in 7 colors that last a long time. We can do this in 7-10 days. Powder coating is good at keeping your parts from rusting, getting chipped, or fading, and it works inside and outside.

Tumbling

We can make your parts smooth and shiny with our tumbling service. We can do this on 13 materials. This makes your parts look good and gets them ready to go

Deburring

We can make your parts smooth and safe with our deburring service. We can do this on 8 materials. This makes sure your parts are safe and fit together right.

Conclusion

Anodizing sheet metal makes your parts last longer, look good, and keep from rusting, making it a great choice for a lot of industries. At Premium Rapid & Mold, we have a lot of other services to make sure your parts are perfect. Call us now to find out how anodizing and our other stuff can help you with your next project.