Are you tired of the high costs and long lead times of mass production for your metal parts? Low volume production might be the answer you’re looking for! It’s perfect for those of you who need high-quality, precision parts without the high cost and long lead times of traditional manufacturing methods.

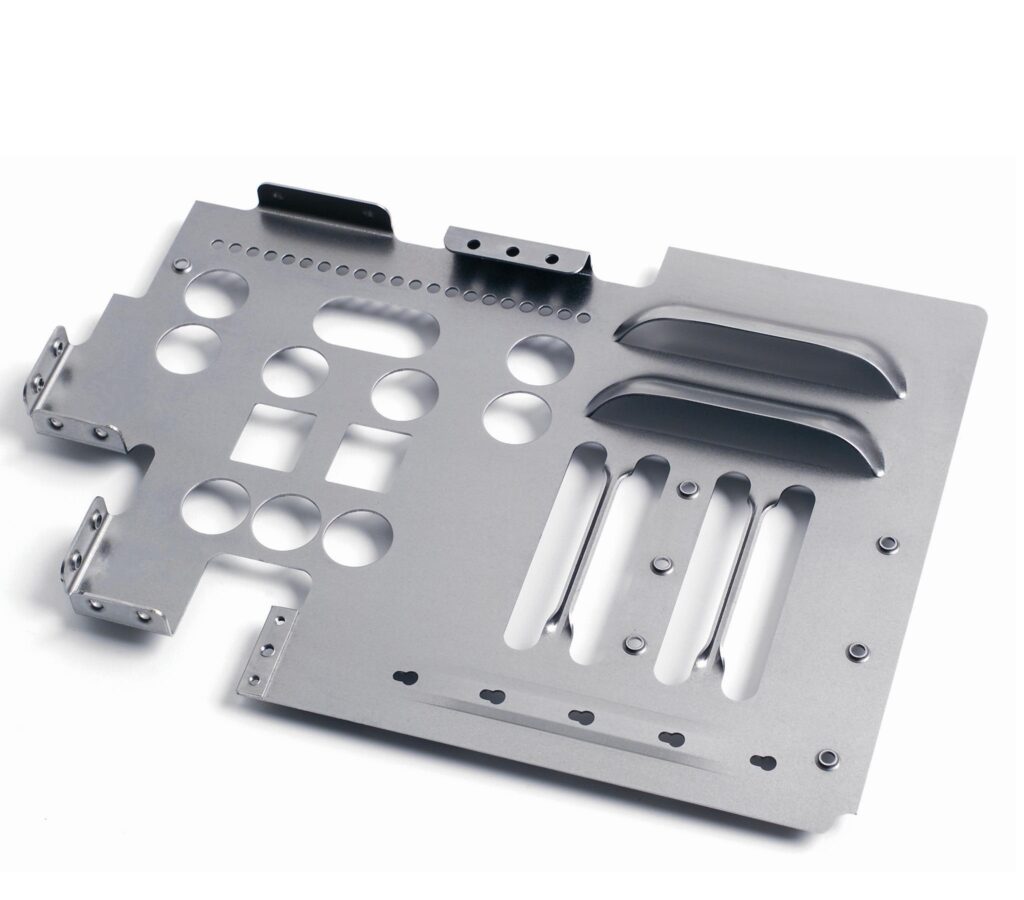

Low volume production of precision sheet metal allows you to produce custom, high-quality parts in smaller quantities, and offers flexibility, cost savings, and quick turnaround times. It’s great for prototyping, small batch production, and projects that require numerous design changes.

If you understand the benefits and how it works, you’ll be able to make an informed decision on whether low volume production is right for your next project. In this blog post, we’ll take a deep dive into low volume production precision sheet metal, including how it works, the benefits, and the industries it serves. By the time we’re finished, you’ll know if this is the right option for you.

What Techniques Are Used in Low Volume Production Precision Sheet Metal?

Low volume production uses several advanced techniques to ensure precision and quality. Here’s a breakdown of the key processes:

Design and Prototyping

It all starts with a detailed design phase. We use CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software to create accurate models of your parts. This step is crucial for precision and to catch any potential issues early. We then move on to prototyping, where we test our designs and make refinements before moving into full production.

Material Selection

Choosing the right material is critical to the success of your project. We offer a variety of materials, such as aluminum, stainless steel, and mild steel, each with its own unique properties. For instance, aluminum is lightweight and corrosion-resistant, making it ideal for aerospace applications, while stainless steel is incredibly durable and formable, perfect for medical equipment.

Cutting and Forming

Laser Cutting

Laser cutting is an extremely precise method, ideal for intricate designs and clean edges. This process uses a high-power laser beam to cut the material, resulting in minimal waste and high accuracy.

Punching

Punching is a quick and efficient way to create holes and cutouts in the sheet metal. This method is particularly useful for high-strength materials and can accommodate different thicknesses with ease.

Forming

Forming involves bending and shaping the metal using CNC (Computer Numerical Control) machines. This process ensures consistent and accurate dimensions, making it perfect for creating complex shapes and angles.

Assembly Processes

Welding / Spot Welding

Welding is critical for creating strong, permanent bonds between metal parts. Spot welding, a variation of welding, is especially effective for quickly and efficiently assembling thin materials.

Hardware Insertion

Inserting hardware components, such as fasteners and inserts, is crucial to ensure your assembled parts are secure and functional. Precision is key here to make sure the hardware fits perfectly.

Assembly

The final stage of assembly is putting all the components together to create the final product. This step requires close attention to detail to ensure the structural integrity and functionality of the product.

Finishing

The finishing touches are essential for both the appearance and durability of the parts. We offer a variety of surface treatments, such as powder coating, anodizing, and plating, to enhance the corrosion resistance and aesthetics of the parts.

What Are the Advantages of Low Volume Production?

Flexibility

One of the biggest benefits of low volume production is flexibility. This method allows you to easily make design changes without incurring significant costs. Whether you need to make a design adjustment based on feedback or iterate multiple times to get the perfect product, low volume production can handle these changes with ease.

Cost-Effectiveness

Low volume production is also cost-effective, especially for small batches. It reduces waste and minimizes inventory costs. Additionally, it avoids high setup costs associated with mass production, making it an economical choice for smaller runs.

Quality Control

Low volume production places a higher emphasis on quality control. We perform thorough inspections at every stage to ensure each part meets the required specifications. This level of scrutiny reduces defects and ensures the final product is of the highest quality.

Lead Time and Turnaround

One of the key advantages of low volume production is the reduced lead time. Through streamlined processes and advanced technology, we can move quickly from design to production, ensuring you receive your parts in a timely manner. This fast turnaround is critical for industries that need rapid prototyping and fast market entry.

Custom Design Assistance

Our team of experienced engineers can help you with custom designs. We work closely with you to understand your specific needs and provide design recommendations that improve manufacturability and functionality. This collaborative approach ensures your final product meets all your requirements while optimizing production efficiency.

Post-Production Support

Post-production support is essential for maintaining the quality and performance of your parts. We offer various post-production services, such as quality checks, packaging, and logistics support. Our goal is to ensure your parts not only meet your expectations but also arrive safely and ready to use.

What Industries Benefit from Low Volume Production Precision Sheet Metal?

Low volume production precision sheet metal serves a wide variety of industries, each with unique needs and applications.

Aerospace

In aerospace, precision and quality are critical. Low volume production allows you to make high-precision components, such as aircraft panels and brackets, with a quick turnaround. The ability to make design changes and produce small batches is especially useful during the development and testing phases of new aircraft.

Automotive

The automotive industry benefits from low volume production for prototyping and specialty vehicles. You can make custom parts, such as enclosures and structural components, quickly, allowing you to iterate and test rapidly. This method also supports the production of limited-edition and high-performance vehicles where customization and precision are essential.

Communications

In communications, precision sheet metal parts are used in devices and infrastructure. Low volume production ensures that components, such as enclosures and brackets, are made to exact specifications, supporting the development of advanced communication technologies.

Electronics

For electronics, low volume production is great for making custom enclosures, brackets, and components. This method allows you to develop and iterate on prototypes quickly, so you can get new electronic devices to market fast.

Instrumentation

In instrumentation, precision is everything. Low volume production allows you to make high-quality, precise parts for measuring and control instruments. This method ensures that each part meets strict industry standards, providing reliability and performance.

Medical

In the medical field, you need precision and reliability. Low volume production helps you make high-quality parts for medical devices and equipment. This method allows you to prototype and produce custom parts quickly, so you can test and deploy medical innovations fast.

Miscellaneous Metals

Custom metal fabrication is crucial for many industries, from construction to art installations. Low volume production gives you the flexibility to make unique, high-quality metal parts to fit your exact needs.

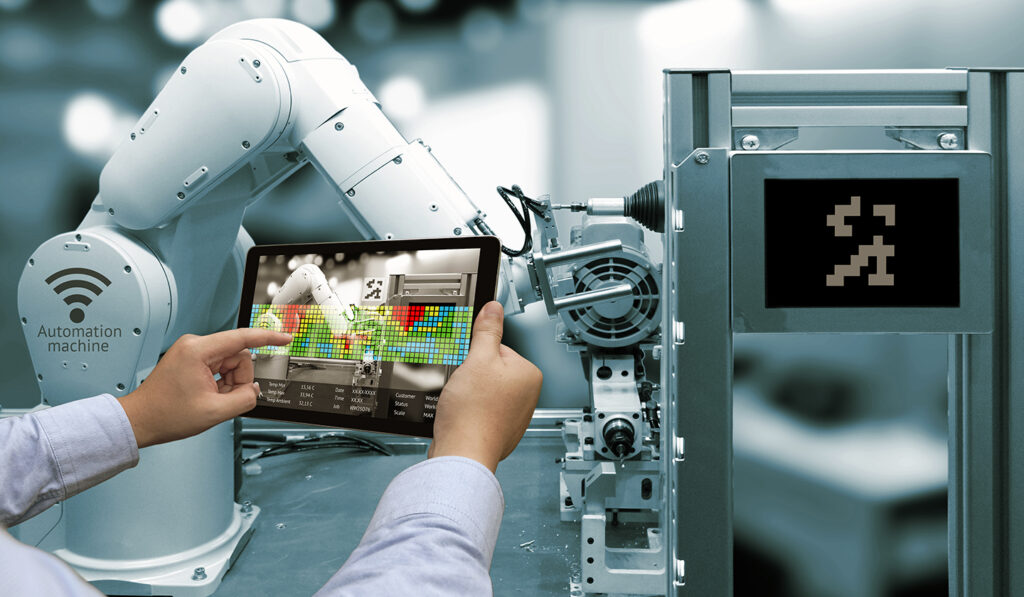

Robotics

In robotics, precision and customization are essential. Low volume production helps you develop robotic systems by providing you with high-quality, custom parts. This method allows you to prototype and iterate quickly, so you can develop and refine robotic innovations efficiently.

Conclusion

Low volume production precision sheet metal provides a flexible, cost-effective solution for producing high-quality, custom parts. Whether you’re in aerospace, automotive, medical, or any other industry, this method can get the job done quickly and accurately. By using advanced techniques like laser cutting, punching, forming, and welding, and offering comprehensive finishing and assembly services, we make sure your project gets done right. Try low volume production for your next project and see the benefits of precision, flexibility, and quality.

Get in touch with us today for a consultation and custom quote tailored to your specific needs. Let’s turn your vision into reality with precision sheet metal fabrication.