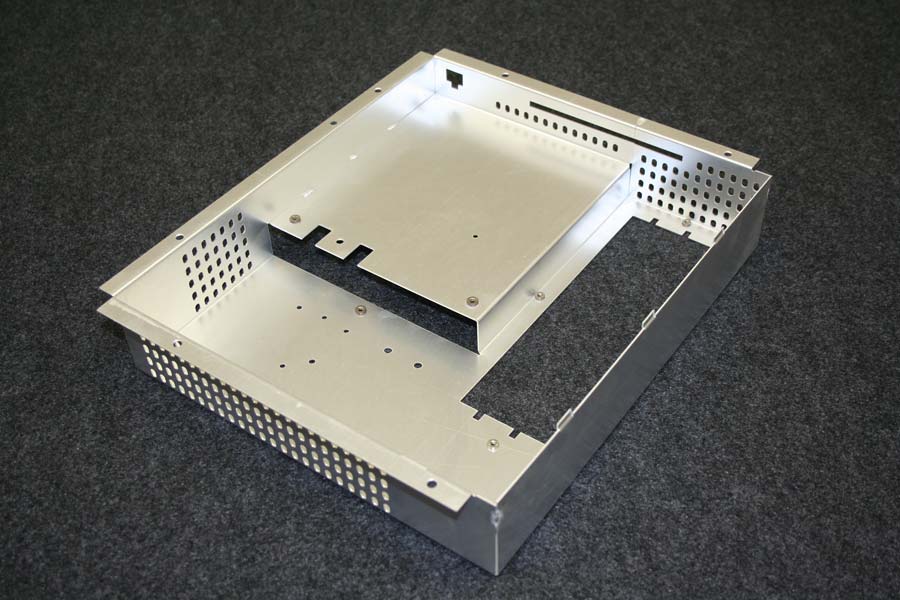

Your high-performance audio equipment deserves an enclosure that combines durability, aesthetic appeal, and precise engineering. Off-the-shelf solutions often fall short, lacking the customization needed to house complex components or meet specific requirements. This limitation leads to increased risks of damage, overheating, and inadequate soundproofing. then with the customized sheet metal fabrication, you can avoid these issues and create enclosures that not only look good but also perform exceptionally well.

Customized sheet metal fabrication offers the flexibility to design audio enclosures that meet specific needs, from complex internal layouts to custom finishing options. It is able to provide the durability and customization needed for high-performance audio systems, ensuring that your equipment is protected and performs optimally.

Standard audio enclosures might get the job done, but they lack the tailored features that distinguish high-end setups. Custom sheet metal fabrication allows you to specify unique shapes, sizes, and internal configurations. This flexibility leads to enclosures that not only fit perfectly into your setup but also offer enhanced heat dissipation, soundproofing, and aesthetic value. With a range of finishing options, you can ensure your enclosures align with your brand’s identity while providing robust protection.

How Does Customized Sheet Metal Fabrication Benefit Audio Enclosures?

Customized sheet metal fabrication offers several advantages over traditional off-the-shelf enclosures. Firstly, it provides the freedom to create unique designs tailored to your equipment. This flexibility is crucial when dealing with high-performance audio setups, where each component’s placement can significantly impact sound quality and system performance.

Additionally, custom fabrication allows you to choose from a variety of materials, such as aluminum, stainless steel, or galvanized steel, each offering unique benefits. Aluminum is lightweight yet durable, ideal for portable setups. Stainless steel provides superior strength and corrosion resistance, perfect for heavy-duty applications. Galvanized steel offers additional corrosion protection, making it suitable for outdoor use.

What Makes Custom Sheet Metal Enclosures More Durable?

Durability is a key factor when choosing audio enclosures. Custom sheet metal fabrication excels in this area by offering robust materials and advanced assembly techniques. The use of precision laser cutting ensures accurate cuts and reduces the risk of material stress. This precision is vital for maintaining the integrity of the enclosure and avoiding weak points that could lead to damage.

In addition, custom sheet metal enclosures benefit from high-quality welding and riveting techniques, providing seamless assembly and enhanced strength. These methods ensure the enclosure can withstand the rigors of transportation, setup, and long-term use without compromising its structural integrity.

How Does Custom Fabrication Enhance Aesthetic Appeal?

Custom sheet metal fabrication isn’t just about durability; it’s also about creating visually appealing enclosures. With a range of finishing options, you can choose the perfect look for your audio equipment. Powder coating is a popular choice, offering a durable finish in various colors and textures. It provides protection against scratches and chipping while allowing you to match your enclosures to your brand’s color scheme.

Silk screening is another option, enabling you to add custom logos, branding, or other design elements to your enclosures. This flexibility allows you to create enclosures that not only perform well but also look professional and cohesive.

How Can Custom Fabrication Improve Functionality?

Functionality is a critical aspect of high-performance audio enclosures. Custom sheet metal fabrication allows you to design enclosures with specific features to enhance functionality. This can include custom cutouts for wiring and components, strategically placed vents for heat dissipation, and soundproofing elements to reduce vibrations and noise leakage.

Custom fabrication also enables you to optimize the internal layout of your enclosures. By working with a fabricator with expertise in audio equipment, you can ensure that your enclosures are designed to meet the unique requirements of your setup. This tailored approach helps you avoid common issues like overheating or interference between components, leading to a more reliable and efficient audio system.

How Does Customized Sheet Metal Fabrication Enhance Thermal Management in Audio Enclosures?

Customized sheet metal fabrication enhances thermal management by allowing for precise design of heat dissipation features. With laser-cut vents, airflow channels, and heat sinks, you can ensure optimal cooling for high-performance audio equipment. This customization is crucial for preventing overheating, a common issue with high-end audio systems. You can work with a fabricator to incorporate advanced thermal solutions, tailoring the design to meet specific cooling requirements. This not only improves the longevity of the equipment but also maintains performance by reducing thermal stress on sensitive components.

What Vibration and Noise Reduction Features Are Possible with Custom Fabrication?

Custom fabrication provides several options for reducing vibrations and noise in audio enclosures. By incorporating internal damping materials, specialized mounting points, and sound-insulating elements, you can significantly reduce unwanted vibrations that could distort audio quality. Custom sheet metal fabrication allows for precise placement of these features, ensuring they work effectively without affecting the overall design. This results in clearer audio output and a more stable enclosure, crucial for maintaining sound quality in high-performance systems.

How Does Customized Sheet Metal Fabrication Protect Against Environmental Factors?

Customized sheet metal fabrication can create enclosures that offer robust protection against environmental factors. This can include moisture-resistant designs, dust-proofing features, and weatherproof seals, ensuring the equipment remains safe in various conditions. By working with a fabricator, you can specify the level of protection needed for your audio equipment, whether it’s intended for indoor or outdoor use. This customization ensures the enclosure’s longevity and reliability, protecting your investment from environmental damage.

How Do Custom Cutouts and Access Panels Improve Audio Enclosures?

Custom cutouts and access panels are a significant advantage of customized sheet metal fabrication. They allow for easy installation and maintenance of internal components without compromising the enclosure’s structural integrity. You can design specific cutouts for wiring, connectors, and other interfaces, ensuring a seamless fit with the rest of your audio setup. Additionally, custom access panels provide convenient entry points for servicing and adjustments, enhancing the overall usability and flexibility of your audio enclosures.

What Security Features Can Be Integrated into Custom Audio Enclosures?

Custom sheet metal fabrication allows for the integration of enhanced security and anti-tampering features. This can include lockable access panels, tamper-resistant fasteners, and reinforced hinges to prevent unauthorized access. By customizing your audio enclosures with these security features, you can ensure the safety and protection of high-end audio equipment. This level of security is especially important for professional setups and public venues, where tampering could lead to significant issues.

How Does Custom Fabrication Ensure Compliance with Industry Standards?

Customized sheet metal fabrication can be designed to meet industry standards and certifications, ensuring compliance with safety regulations, electromagnetic compatibility (EMC) requirements, and other industry-specific guidelines. By collaborating with a fabricator with experience in the audio industry, you can ensure your enclosures meet all necessary standards. This compliance is crucial for audio equipment used in professional settings, as it provides peace of mind and aligns with industry regulations. Custom fabrication allows you to incorporate these requirements into the design without compromising on functionality or aesthetics.

Conclusion

Customized sheet metal fabrication offers numerous advantages for high-performance audio enclosures, addressing key concerns like thermal management, vibration reduction, environmental protection, and security. It allows for customized cutouts, enhanced security features, and compliance with industry standards. This level of flexibility ensures that your enclosures are tailored to specific needs, optimizing performance and durability.

With a trusted fabricator like Premium Rapid & Mold, you get the benefits of advanced fabrication techniques and a range of finishing options, ensuring your audio enclosures are both functional and visually appealing.