Are you struggling to find metal frames that are durable and accurate for your products? Are you tired of paying too much and getting frames that don’t work the way you need them to? Learn how custom sheet metal frames can solve your problems. At Premium Rapid & Mold, we understand the value of getting custom solutions that work for your unique needs across a wide range of industries. We make sure you get the best products at the best prices so you can increase the efficiency and reliability of your business.

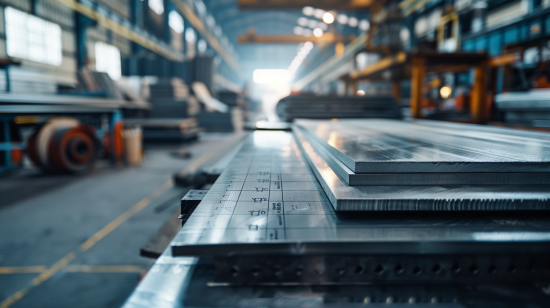

Custom sheet metal frames are important because they are durable, accurate, and flexible. They’re built to meet the specific needs of your industry, so your products perform better and cost less. When you use custom frames, you can overcome unique challenges, eliminate assembly issues, and create better products.

Imagine having frames that are perfect for your application, so you don’t have to worry about putting them together wrong and your products last longer. Custom sheet metal frames make that happen and are essential for industries like automotive, aerospace, medical equipment, and more. Let’s talk about why you need these custom solutions for your business and how we can help you at Premium Rapid & Mold.

What Makes Custom Sheet Metal Frames Better ?

Custom sheet metal frames last longer. Unlike standard frames, they are designed to work in specific conditions and environments. That means they are made to last and you won’t have to replace them as often. Custom frames are also more accurate, which matters when you need to get the measurements right. For example, in aerospace, even a small mistake can cause big problems.

Custom frames are also more flexible in design. You can make them in shapes and sizes that standard frames can’t. This means you can create new solutions that make your products look better and work better. For example, custom frames in consumer electronics can be made to make the devices look and feel better, giving you an edge over your competition.

Why Are Custom Materials Important?

The material you use for your custom sheet metal frames is important. Different industries need different things, and the material you choose can make a big difference in how your frames work and how long they last. For example, aluminum is lightweight and won’t corrode, so it’s great for aerospace and automotive. Stainless steel is really strong and looks good, so it’s perfect for medical and consumer electronics.

At Premium Rapid & Mold, we work with materials like aluminum, stainless steel, mild steel, and special metals like Inconel and Titanium. This means we can make the frames you need for your industry to work the way you want them to. We know what materials to use and how to make your frames so they work great and last a long time.

How Does the Fabrication Process Work?

We start by talking with you to figure out what you need. We work with you to design the frame you need to work the way you want it to. This is important so that you get what you want and it works the way you expect it to.

Once we know what you need, we use tools like lasers and CNC machines to cut the frames to the exact size you need. This is important because it makes sure you get the right size and the right shape. We use tools that make your frames fit together right and work right.

We use techniques like bending and forming to make the frames into the right shape. We use tools like brake presses and roll forming to make sure your frames look right and work right.

We use different techniques like welding, riveting, and bolting to put the frames together. This makes sure your frames are strong and will last a long time. Finally, we offer different finishes like powder coating and plating to make your frames look good and to make sure they won’t rust.

This way, you get frames that work right, look good, and will last a long time.

What Are the Key Applications?

Custom sheet metal frames are used in a lot of different industries because they are so versatile and reliable. In automotive, custom frames are used for the chassis and other structural parts. These frames are strong and accurate, so the cars are safe and work the way you want them to.

In medical devices, you need frames that are accurate and protect sensitive devices. These frames have to meet strict standards and keep the equipment safe. In consumer electronics, custom frames are used to hold and protect different devices, so they work better and look better.

In industrial applications, custom sheet metal frames are used to hold up machines and heavy equipment. In aerospace, lightweight and strong frames are used for parts on airplanes to make sure they work well and are safe. In telecommunications and renewable energy, custom frames are used for things like 5G equipment and solar panels.

Why Choose Premium Rapid & Mold?

At Premium Rapid & Mold, we have a team of engineers, sheet metal guys, and laser people who make sure every part is perfect. We have been doing this for over 10 years and can help you with what you need. We can help you from the start to make sure you get what you want.

We use the best technology and machines to make sure your parts are perfect and made quickly. We check every part to make sure it’s perfect and works the way you want it to. We work fast and don’t charge a lot of money, so you can trust us to make your parts right.

We send our parts all over the world to places like Europe, North America, and Australia. We’re also careful with the environment and make sure we don’t waste anything when we make your parts. When you work with Premium Rapid & Mold, you get the parts you need to make your products work better and make you happy.

How Do We Ensure Quality?

We make sure the parts are right by checking them at every step. We use the latest technology to make sure the parts are the right size and shape. Our people know what they’re doing and watch every step from start to finish. This means you get the best parts that work the way you want and last a long time.

What Are Some Success Stories?

Our frames have helped a lot of people in different industries. In cars, we have made custom chassis and frame parts that make cars better and safer. We have made frames for medical devices that are reliable and meet strict standards.

In airplanes, we have made strong and lightweight frames that make airplane parts better and safer. We have made custom frames for solar panels that make them work better and get more energy. These are just some of the stories of how we have helped people with their frames.

Conclusion

Custom sheet metal frames are important in a lot of industries because they are durable, accurate, and flexible. At Premium Rapid & Mold, we are the best at what we do. We make sure you get the parts you want, the way you want them. When you work with us, you get the best parts to make your products work better and make you happy. Call us today to get a quote and find out why the biggest companies in the world trust us to make their custom sheet metal parts.