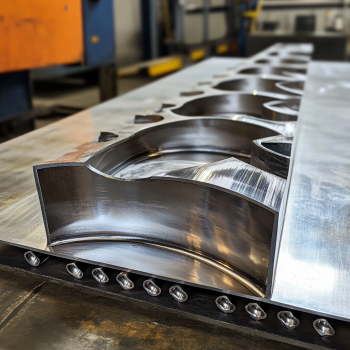

Sheet metal bending requires precision to make quality parts. But what happens when you get die marks on your nice work? Die marks are those little dents or scratches you get in the sheet metal. They can make a perfect job look bad. If you understand how they happen and how to avoid them, you can keep your sheet metal work looking good.

Die marks in sheet metal bending are dents or scratches in the sheet metal caused by contact with the tools (dies) used during the bending process. These marks can affect how your part looks and how strong it is. But you can minimize or eliminate them by using the right techniques and tools.

If you’ve ever had die marks in your sheet metal parts, you’re not alone. Everyone in this industry has struggled with die marks. They make your job look bad and can even mess up how the part works. But don’t worry. You can avoid die marks. In this post, you’ll learn what causes die marks, the different kinds of die marks, and most importantly, how to avoid them. You’ll also learn what to do if you get die marks and how to fix them so your parts look great.

What Exactly Are Die Marks in Sheet Metal Bending?

Die marks are the unsightly impressions on the surface of a piece of sheet metal caused by contact with the die — a tool that forms the metal by applying pressure. The amount of pressure, the condition of the die, and the type of material being bent all play a role in whether die marks will appear and how severe they will be.

Why Do Die Marks Occur?

Die marks happen when the metal contacts the die under high pressure. Here are the factors that contribute to die marks:

• Pressure and Friction: The die applies a lot of pressure to the metal during bending. This pressure, combined with friction, causes the die to leave marks on the sheet metal.

• Material Properties: Softer metals, such as aluminum, are more likely to get die marks than harder metals like steel. The malleability of the material affects how it responds to the pressure from the die.

• Die Condition: A worn-out or damaged die is more likely to leave marks. Even small defects on the surface of the die can lead to noticeable marks on the bent metal.

What Types of Die Marks Are There?

Die marks can take on different forms and levels of severity. Here are the most common types:

• Surface Scratches: These are light, shallow marks caused by slight contact or friction between the metal and the die.

• Indentations: These are deeper marks caused by higher pressure or sharp edges on the die. Sometimes, these can weaken the metal at the point of contact.

• Tool Marks: These are specific patterns or repeated marks left by imperfections in the die. These are often a sign that the die needs to be maintained or replaced.

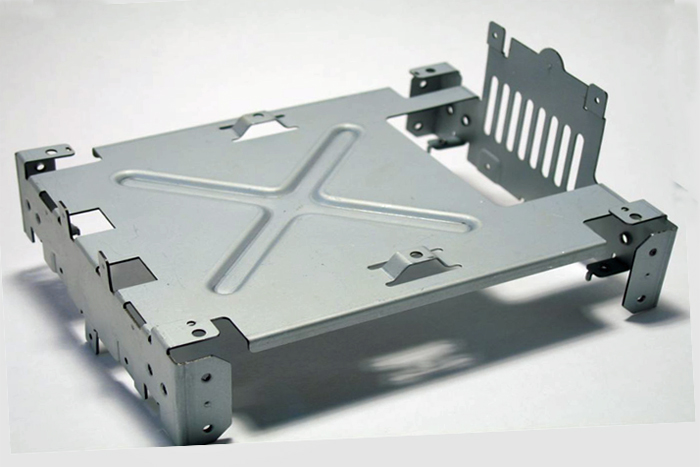

How Do Die Marks Affect Product Quality?

Die marks are more than just a cosmetic problem. They can have a big impact on the quality and performance of your part:

• Aesthetic Issues: Die marks can make your part look bad. This is a big deal, especially if the part is visible in the final assembly.

• Structural Concerns: In some cases, die marks can weaken the material, causing the part to fail under stress. Indentations, in particular, can create weak spots.

• Impact on Finishing Processes: If your part is going to be painted or coated, die marks can cause the paint to go on unevenly, leading to more problems.

How Can You Prevent Die Marks in Sheet Metal Bending?

Preventing die marks is always better than trying to fix them. Here are some ways to keep die marks from happening in the first place:

- Use Protective Films or Coatings

Putting a thin film or coating on the sheet metal before you bend it can help prevent die marks. These coatings act as a barrier, stopping the metal from touching the die directly.

- Maintain and Polish Your Dies

It’s important to keep your dies in good shape. This includes polishing them to make sure they don’t have any imperfections that will mark the metal. If the die is smooth, it will bend the metal without leaving marks.

- Optimize Your Die Design

Think about using dies with rounded edges or smooth surfaces. Sharp edges can cause marks, so making your die just right can help prevent them. Custom dies made specifically for the material you’re bending can also help a lot.

- Adjust Your Bending Pressure

Sometimes, changing the pressure you use to bend the metal can help prevent die marks. If you use less force, you’re less likely to leave marks, especially on softer materials.

- Think About the Material

• Aluminum: Aluminum is soft and gets die marks easily. To keep them to a minimum, you can bend aluminum with less pressure. You can also use special dies made for aluminum to help prevent marks.

• Stainless Steel: Stainless steel is harder and less likely to get die marks, but it can still happen if the die isn’t in good shape. You need to be precise with stainless steel to make sure you don’t get marks.

- Lubrication

• Use Lubricants: Putting a lubricant on the metal while you bend it can help reduce the friction between the die and the metal, which can help prevent die marks. This is especially helpful if you have a lot of friction or if you’re bending sticky materials like stainless steel.

- Advanced Die Technology

• Coated Dies: Coated dies (with Teflon or other nonstick materials) can reduce friction and keep you from getting die marks. These coatings can also make your die last longer and make your parts look better.

• Precision-Ground Dies: These are dies that have been made to have a very smooth surface. They are made to keep the metal from getting marks when you bend it. These are especially useful if you need a smooth surface on your part.

What Should You Do If Die Marks Occur?

Even if you do everything right, sometimes you still get die marks. Here’s what you can do:

1. Sanding and Polishing

For small die marks, you can sand and polish the area to smooth it out. This works well for light surface scratches.

2. Chemical Treatments

Sometimes, you can use chemicals to get rid of or reduce die marks. These chemicals etch the top layer of the metal, taking the marks off with it.

3. Reworking the Part

If you can’t fix the die marks, you might have to rework the part. This might mean bending the metal again with a different die or doing something more drastic to the surface.

4. Accepting Minor Imperfections

If the marks are just on the surface and don’t affect how the part works, you might be able to just leave them. This should be a last resort and only done if you and your customer agree.

How Die Marks Affect Tolerance

- Tolerance Issues: Die marks can mess with how big the part is, which can be a big problem in precision work. If the die marks change the size of the part, it might not fit right or work right in the final assembly. Managing die marks is important if you need the part to be the exact right size, especially in industries where everything has to be perfect.

How Can Die Marks Affect Your Bottom Line?

Die marks can cost you a lot of money in both making the part and finishing the part. You might have to rework parts, put on extra finishes, or even throw parts away if they’re too damaged. Also, if you send a part with die marks to a customer, you’ll look bad and make them mad.

Why You Should Care About Die Marks?

Preventing die marks means you’ll make better parts and not have to throw away as many. By getting good tools, keeping them in good shape, and handling them right, you’ll save time and money and make your customers happy.

Conclusion

Die marks happen to everyone who bends sheet metal. However, they don’t have to ruin your parts. By understanding why they happen and using the right techniques to prevent them, you can keep your sheet metal looking good. Remember to maintain your dies, use protective coatings, lubricants, advanced die technology, and control your bending process to keep die marks from happening. By following these steps, you can make high-quality parts your customers will be happy with.