Are you tired of corrosion on your metal parts, or are you looking for a finish that can add both durability and visual appeal? Worse still, many surface treatments fail to stand the test of time, peeling or flaking off under pressure. Anodizing could be the answer you’re looking for, offering a protective, long-lasting solution that enhances both the durability and appearance of metal parts.

Anodizing is a highly effective surface treatment for metal parts, especially aluminum. It provides a durable, corrosion-resistant finish that extends the life of components, making it ideal for industries like automotive, aerospace, and electronics. The anodizing process also improves wear resistance and allows for color customization, giving your products both protection and aesthetic flexibility.

Want to learn more about why anodizing could be the right choice for your metal parts? Read on as we explore the process, types, benefits, and challenges of anodizing.

What Is Anodizing, and How Does It Work?

Anodizing is a process that strengthens the surface of metal parts, usually aluminum, by creating a protective oxide layer through an electrochemical conversion. You take the metal part, submerge it in an acid electrolyte bath, and pass an electric current through it to oxidize the surface. This creates a hard, durable layer that improves corrosion resistance, wear resistance, and electrical insulation.

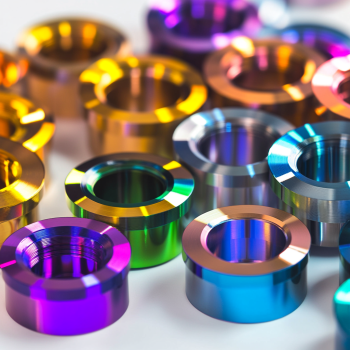

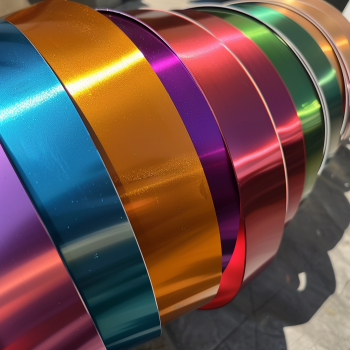

Not only does anodizing make the metal stronger, but it also allows you to customize it. The porous oxide layer can be dyed a variety of colors, creating both functional and decorative finishes.

Why Should You Consider Anodizing for Your Metal Parts?

Anodizing offers many benefits:

• Better Corrosion Resistance: The anodized layer protects metal parts from tough environments, making it great for outdoor and high-humidity applications.

• Greater Durability: The oxide layer created through anodizing is much harder than the base metal, making it more wear-resistant.

• Color and Aesthetic Options: Anodizing gives you a variety of color choices, helping your parts look good and stay protected.

• Environmentally Friendly: The anodizing process is environmentally friendly because it doesn’t produce harmful emissions or use toxic materials.

In short, anodizing offers both aesthetic and practical benefits for your metal parts, making it a great choice for industries that need long-lasting, durable finishes.

Different Types of Anodizing

When you’re considering anodizing, it’s essential to know the different types available so you can choose the best one for your application:

Type I – Chromic Acid Anodizing

Chromic acid anodizing creates a thin oxide layer, which is great for applications that require tight tolerances and lightweight parts. While it doesn’t offer as much wear resistance, it provides excellent corrosion protection and is often used in aerospace components.

Type II – Sulfuric Acid Anodizing

The most common type, sulfuric acid anodizing, makes a thicker oxide layer than Type I. It’s great for applications that need to be durable and look good. You can also dye it in many colors, making it popular for consumer goods and electronics.

Type III – Hardcoat Anodizing (Hard Anodizing)

Type III anodizing creates a very thick and hard oxide layer. It’s perfect for parts that take a lot of abuse, like in military or heavy industrial applications. While this thicker layer might change the dimensions of your part slightly, it offers excellent durability and wear resistance.

Which Type Should You Choose?

- Type I: Use it for parts that need to be close to their original dimensions and need to resist corrosion.

- Type II: Choose it for parts that need to last and for parts that need to be different colors.

- Type III: Go with it for parts that you’re going to beat up or parts that will see a lot of wear.

Can Anodizing Enhance the Appearance of Metal Parts?

Absolutely! One of the great things about anodizing is that it doesn’t just protect your parts—it makes them look great, too. The porous nature of the anodized layer allows for dyeing, which means you can color your parts however you want. Whether you need sleek black finishes for electronics or bright, bold colors for identification purposes, anodizing gives you a tough and good-looking solution.

Can You Get the Same Color Every Time?

Yes, you can, but it depends on the alloy and the process. A good anodizing company will have strict quality control to ensure that every part is the same color and finish, even if you’re doing a lot of them.

What Are the Environmental Considerations?

Anodizing is a “green” surface treatment process. It uses sulfuric acid, which isn’t toxic, and it doesn’t release VOCs (volatile organic compounds) like painting or powder coating. Plus, anodizing by-products can be recycled and disposed of responsibly.

Is Anodizing an Eco-Friendly Process?

Yes. It is considered environmentally friendly because it doesn’t release harmful emissions, and the materials used in the process are recyclable. If you’re trying to be green, anodizing is a great option.

What Are the Main Challenges of Anodizing?

Like anything, anodizing has its challenges:

• Getting the Same Color: It can be tough to get the same color or finish, especially when you’re working with different alloys or complex parts.

• Changing Dimensions: Anodizing adds a layer to the surface, which can affect parts that have to be a certain size.

• Cost: Custom anodizing, especially for small jobs, can be more expensive than other surface treatments. However, the durability you get from anodizing usually makes the cost worth it.

How Can You Overcome These Challenges?

You overcome these challenges by working with an experienced anodizing company. They’ll know how to account for changes in size, make sure your parts are all the same color, and work with you on the cost to get you the finish you need.

How to Choose the Right Anodizing Service Provider?

Picking the right company is key to getting the best finish on your anodized parts. Look for a company with a good reputation, the right technology, and quality certifications. Ask them about their experience with the type of anodizing you need, and how they keep all your parts the same color.

Questions to Ask Your Provider:

- What experience do you have with this type of anodizing?

- How do you make sure all the parts look the same, especially if I give you a big order?

- What do you do for quality control?

- Do you have the right certifications?

Conclusion

Anodizing is a great way to make your metal parts stronger, more durable, and better-looking. It can help you in industries like aerospace, automotive, and electronics where you need your parts to work well and look good. By understanding the different types of anodizing and working with a good anodizing company, you can be sure your parts will work well and look good.

So, if you need a finish for your project that will last, resist corrosion, and look good, anodizing is probably the way to go.