Are you struggling to find a reliable way to manufacture your metal components? Frustrated with inconsistent quality or delayed deliveries? You’re not alone. Many businesses face these challenges. Sheet metal fabrication might just be the solution you need. This process not only offers precision and efficiency but also ensures high-quality results, tailored to your exact specifications.

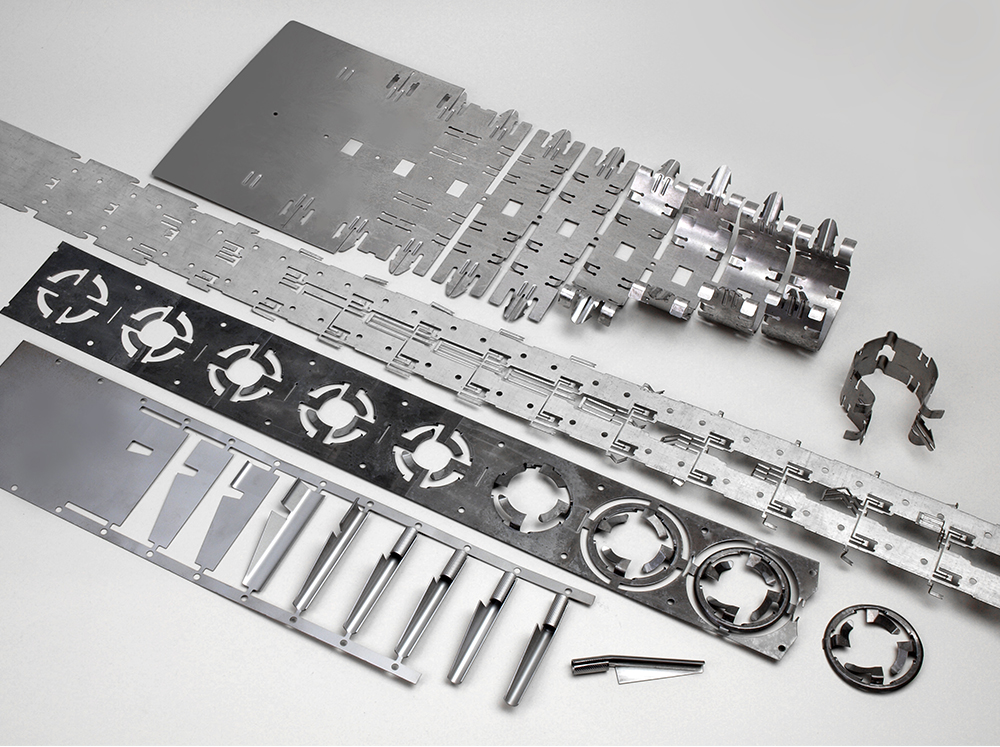

Sheet metal fabrication is the process of forming metal sheets into various shapes and sizes through cutting, forming, and joining techniques. It is widely used in industries such as automotive, aerospace, electronics, and more due to its versatility, durability, and cost-effectiveness.

If you’re still wondering whether sheet metal fabrication is the right choice for your business, keep reading. This post will delve deeper into the process, techniques, and benefits of sheet metal fabrication. By the end, you’ll have a clear understanding of how it can meet your production needs and why it’s a preferred method in many industries.

What is Sheet Metal Fabrication?

Sheet metal fabrication is the process of transforming flat metal sheets into specific shapes and structures using cutting, forming, and joining techniques. This versatile process involves methods such as laser cutting, bending, welding, and stamping to create components used in various industries, including automotive, aerospace, and electronics. Materials commonly used include steel, aluminum, copper, and stainless steel. Fabricated sheet metal parts are known for their durability, precision, and adaptability, making them essential for manufacturing robust and intricate designs efficiently and cost-effectively.

3 Types of Sheet Metal Fabrication Techniques

Cutting

Cutting is the first step in the sheet metal fabrication process. It involves resizing the metal sheet into manageable pieces or specific shapes. There are several cutting methods, each suited for different applications and materials:

- Laser Cutting: This method uses a high-powered laser beam to cut the metal. It offers high precision and clean edges, making it ideal for intricate designs. Laser cutting can achieve tolerances as tight as ±0.1 mm.

- Plasma Cutting: This technique uses a jet of ionized gas (plasma) to cut through the metal. It is cost-effective for thicker materials and widely used in industrial applications.

- Shearing: Shearing involves cutting straight lines on flat metal stock without forming chips or burning the material. It is quick and efficient for making straight cuts, perfect for high-volume production.

Without Shear

These cutting methods do not involve shearing the metal but rather use advanced technologies to achieve precise cuts.

Laser Cutting:

- High Precision: Laser cutting can achieve extremely tight tolerances, making it ideal for intricate and detailed designs.

- Clean Edges: The laser beam melts, burns, or vaporizes the material, leaving smooth and clean edges.

- Versatility: Suitable for a wide range of materials including steel, aluminum, and even plastics.

Plasma Cutting:

- Cost-effective for Thicker Materials: Plasma cutting is more affordable than laser cutting for thicker materials.

- Speed: It can cut through thick metal quickly, making it suitable for heavy-duty applications.

- Versatility: Can cut through conductive materials of various thicknesses.

Waterjet Cutting:

- Suitable for Heat-sensitive Materials: Waterjet cutting does not generate heat, preventing warping or distortion of the material.

- Precision: Capable of producing intricate cuts with high accuracy.

- Environmental Benefits: Uses water and abrasive materials, making it an environmentally friendly option.

With Shear

Shearing methods involve cutting straight lines on flat metal stock without forming chips or burning the material.

Shearing:

- Quick and Efficient: Shearing is a fast process, ideal for high-volume production.

- Straight Cuts: Best for making straight cuts in sheet metal.

- Limitations: Not suitable for intricate designs or detailed work.

Forming

Forming processes shape the cut metal pieces into the desired configurations. Key forming techniques include:

Bending

Bending uses machines like press brakes or folding machines to create precise angles and curves in the metal sheet.

Techniques:

- Press Brakes: Use a punch and die to bend the metal. The precision and repeatability of press brakes make them ideal for high-quality bends in structural applications and enclosures.

- Folding Machines: Use a clamping beam to hold the metal while a folding beam lifts and folds the material to the desired angle.

- Applications: Bent sheet metal parts are often used in structural applications, enclosures, and brackets. For instance, enclosures for electrical panels often require precise bending to fit components perfectly.

Hemming

Hemming involves folding the edge of the metal sheet back onto itself to create a smooth edge or reinforce the part.

- Process: The edge of the metal is bent and then flattened to create a seam. This seam can be open (a small gap) or closed (edges touch).

- Applications: Hemming is commonly used in automotive body parts to create smooth, safe edges and to increase the part’s strength. It’s also used in appliances and metal furniture to avoid sharp edges.

Curling

Curling rolls the edge of the sheet metal into a tube-like shape. This process is used to eliminate sharp edges and add strength to the part.

- Process: The edge is bent around a form or roller to create a curved edge.

- Applications: Curling is used in products like metal containers, trays, and panels to create safe, rounded edges and improve structural integrity.

Rolling

Rolling passes the sheet metal through a series of rollers to create cylindrical shapes.

- Process: The metal sheet is gradually bent into a round shape as it passes through the rollers.

- Applications: Commonly used for producing pipes, tubes, and cylindrical tanks. For example, pipes for plumbing and HVAC systems are typically produced through rolling.

Roll Forming

Roll forming is a continuous bending process where a long strip of metal is passed through consecutive sets of rollers to form a specific shape.

- Process: The metal strip is bent incrementally by each set of rollers until the final shape is achieved.

- Applications: Ideal for producing long parts with consistent cross-sections, such as rails, frames, and structural sections used in construction and automotive industries.

Metal Spinning

Metal spinning involves rotating a metal disc on a lathe and shaping it with a tool to create axially symmetric parts.

- Process: The metal disc is clamped onto a lathe and rotated while a tool presses against it, shaping the metal into the desired form.

- Applications: Used to produce parts like automotive wheels, satellite dishes, and cooking pots, where the symmetry and smooth surface finish are essential.

Deep Drawing

Deep drawing stretches the metal sheet into a shape by pulling it into a die cavity.

- Process: The metal is clamped, and a punch is used to draw it into the die, forming a deep, hollow shape.

- Applications: Used for creating complex, hollow shapes like fuel tanks, kitchen sinks, and beverage cans. Deep drawing is preferred for parts that require significant depth and smooth, seamless surfaces.

Stamping

Stamping combines cutting and forming processes using dies to achieve complex parts in fewer steps. This can be done through:

Progressive Stamping

Progressive stamping involves multiple stamping stations, each performing a different operation, gradually shaping the part until it is complete.

- Process: The metal strip is fed through a series of dies, each performing a specific operation such as cutting, bending, or punching.

- Applications: Efficient for high-volume production runs. Used in manufacturing components like brackets, clips, and electronic connectors where multiple steps are required to achieve the final shape.

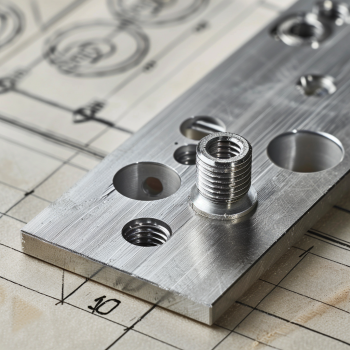

Holemaking and Threading

Making holes in sheet metal is crucial for many applications. Techniques include:

Laser Cutting and Punching

These methods offer precision and efficiency for creating holes in metal sheets. Laser cutting uses a focused beam to melt and remove material, while punching uses a die to mechanically remove a portion of the metal.

CNC Mill, Drill Press, and Hand Drill

- CNC Mill: Provides the highest precision for creating holes and threads in metal parts. CNC machines are computer-controlled and can produce consistent, accurate results.

- Drill Press: Offers good precision and is suitable for repetitive holemaking tasks. Drill presses are commonly used in workshops for their stability and accuracy.

- Hand Drill: Provides flexibility and is useful for on-site adjustments, though it offers less precision compared to CNC machines and drill presses.

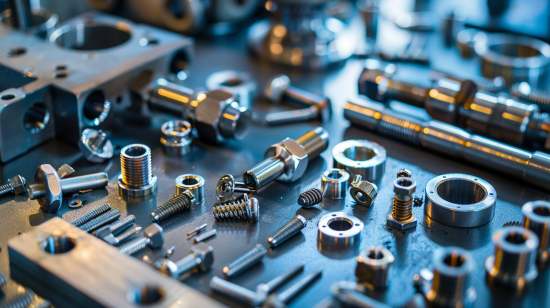

Sheet Metal Fabrication Joining Techniques

Joining processes are essential for assembling metal parts into final products. Key techniques include:

Welding

Welding is one of the most common methods for joining metal parts permanently. It involves melting the edges of the metal pieces to fuse them together.

- MIG (Metal Inert Gas) Welding: Uses a continuous wire feed as an electrode and an inert gas to shield the weld from contamination. MIG welding is fast and versatile, suitable for various thicknesses of metal.

- TIG (Tungsten Inert Gas) Welding: Uses a non-consumable tungsten electrode and an inert gas. TIG welding provides high-quality, precise welds, ideal for thinner materials and detailed work.

- Spot Welding: Involves welding at specific points using electrical resistance to generate heat. It is commonly used for joining sheet metal parts in automotive and appliance manufacturing.

Riveting

Riveting is a mechanical fastening method used to join metal sheets without welding.

- Process: A rivet is inserted into pre-drilled holes in the metal sheets and then deformed to hold the pieces together securely.

- Applications: Common in applications where welding is not feasible or desirable, such as in aircraft construction, where the heat from welding could weaken the metal or where accessibility is an issue.

Adhesive Bonding

Adhesive bonding uses special adhesives to join metal parts.

- Process: The adhesive is applied to the surfaces to be joined, and the parts are held together until the adhesive cures.

- Applications: Useful for joining dissimilar materials or where heat from welding could cause issues. It is commonly used in the automotive and aerospace industries for attaching lightweight components.

Advantages of Sheet Metal Manufacturing

Sheet metal fabrication offers several advantages:

Durability

Fabricated metal parts are long-lasting and resistant to wear and tear. Metals such as steel and aluminum provide excellent durability, making them suitable for applications that require strength and resilience, such as automotive and industrial machinery.

Versatility

The process can adapt to various designs and applications, making it suitable for many industries. Sheet metal fabrication techniques like bending, rolling, and stamping allow for a wide range of shapes and sizes, accommodating complex designs and functional requirements.

Cost-effectiveness

It is economical for both small and large production runs, reducing overall manufacturing costs. Modern fabrication techniques such as laser cutting and automated forming processes enhance efficiency, minimizing waste and labor costs. This makes sheet metal fabrication a cost-effective solution for both prototypes and large-scale production.

Customization

Tailored solutions meet specific requirements, providing flexibility in design and production. Custom sheet metal fabrication allows for precise specifications, ensuring that the final product fits the intended application perfectly. This customization capability is crucial for industries like aerospace and medical devices, where exact dimensions and performance characteristics are essential.

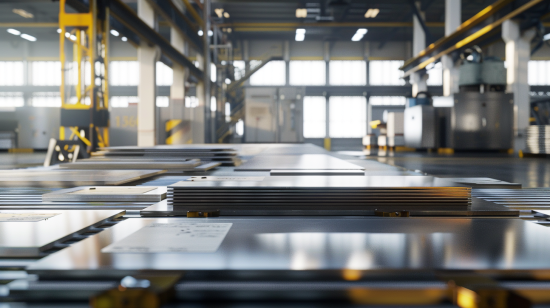

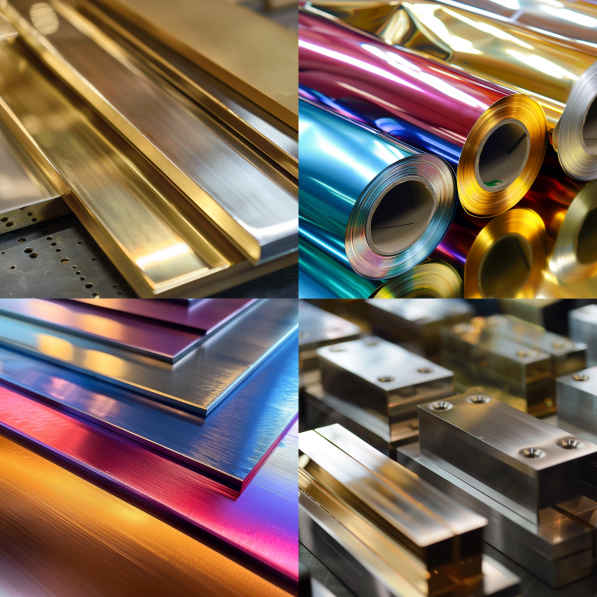

Available Sheet Metal Fabrication Materials

Sheet metal fabrication can utilize a variety of materials, each offering unique properties suitable for different applications. Here are some of the most common materials used in sheet metal fabrication:

- Steel: Known for its strength and durability, steel is widely used in construction, automotive, and industrial applications. It is ideal for heavy-duty parts that require high strength.

- Aluminum: Lightweight and corrosion-resistant, aluminum is perfect for aerospace and automotive applications. It is also used in consumer electronics due to its excellent thermal conductivity and non-toxic properties.

- Copper: With excellent electrical conductivity, copper is commonly used in electrical components and wiring. It also has good thermal conductivity, making it suitable for heat exchangers and plumbing.

- Brass: Combining strength with corrosion resistance and a good aesthetic appearance, brass is often used for decorative items, musical instruments, and fittings.

- Stainless Steel: Known for its corrosion resistance and strength, stainless steel is used in medical instruments, kitchen appliances, and architectural structures. It is also favored in the food and pharmaceutical industries due to its hygiene properties.

- Galvanized Steel: Steel coated with a layer of zinc for enhanced corrosion resistance. It is commonly used in outdoor structures, roofing, and automotive parts.

- Titanium: Offers a high strength-to-weight ratio and corrosion resistance, making it ideal for aerospace, medical implants, and high-performance equipment.

- Nickel: Known for its corrosion resistance and high-temperature performance, nickel is used in chemical processing equipment, batteries, and aerospace components.

- Zinc: Often used for galvanizing other metals to protect them from corrosion. It is also used in die-casting alloys and various mechanical parts.

Surface Finishes for Sheet Metal Fabrication

Surface finishes enhance the appearance and performance of fabricated parts. They provide corrosion resistance, improve aesthetics, and can add functional properties to the parts. Here are some common surface finishes:

- Powder Coating: Provides a durable, corrosion-resistant layer. Powder coating can be applied in various colors and textures, making it suitable for both functional and decorative applications.

- Anodizing: Primarily used for aluminum parts, anodizing enhances corrosion resistance and aesthetic appeal. It also allows for coloring of the metal surface.

- Electroplating: Methods like chrome, nickel, and zinc plating add a protective layer and improve appearance. This finish is often used in automotive and consumer electronics.

- Galvanizing: A process of applying a protective zinc coating to steel or iron to prevent rusting. It is commonly used in outdoor and construction applications.

- Polishing: Improves the surface finish by making it smooth and shiny. Polishing is often used for aesthetic purposes in consumer products and architectural components.

- Brushing: Creates a uniform, linear scratch pattern on the surface, enhancing the appearance and texture. It is commonly used for stainless steel parts.

- Painting: Provides both aesthetic and protective benefits. Paint can be applied in various colors and finishes to match specific design requirements.

- Passivation: Enhances the corrosion resistance of stainless steel by removing surface contaminants and forming a protective oxide layer.

- Chemical Etching: Creates intricate designs and patterns on the metal surface. This finish is used for decorative purposes and in applications requiring detailed graphics.

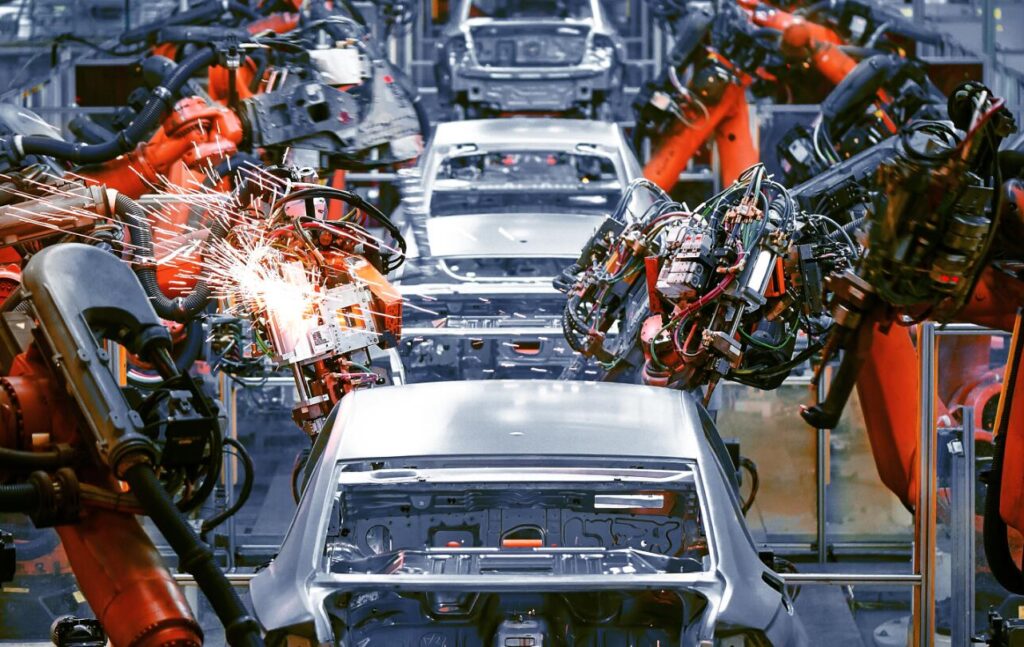

Industrial Applications of Sheet Metal Fabrication Parts

Sheet metal fabrication is essential in various industries due to its versatility and durability. Here are some key applications:

- Automotive: Used for body panels, chassis, and other components. The strength and durability of sheet metal make it ideal for automotive parts that need to withstand impact and wear.

- Aerospace: Critical for parts that require high precision and strength. Sheet metal is used for aircraft bodies, wings, and engine components.

- Consumer Electronics: Enclosures and structural components benefit from sheet metal’s durability and precision. It is used in the manufacturing of cases, frames, and mounting brackets.

- Industrial Equipment: Machinery and tools rely on sheet metal parts for robustness and reliability. Components like frames, housings, and supports are commonly fabricated from sheet metal.

- Medical Devices: Precision and hygiene are crucial. Sheet metal is used to fabricate surgical instruments, diagnostic equipment, and hospital fixtures.

- Construction: Structural components such as beams, columns, and cladding panels are made from sheet metal due to its strength and versatility.

- HVAC Systems: Ductwork, vents, and housings are fabricated from sheet metal to ensure durability and efficient air flow in heating, ventilation, and air conditioning systems.

- Lighting: Enclosures and reflectors in lighting fixtures are often made from sheet metal, providing durability and precise shapes for optimal light distribution.

- Agricultural Equipment: Sheet metal is used in the manufacturing of machinery and tools for farming, such as plows, harvesters, and storage silos.

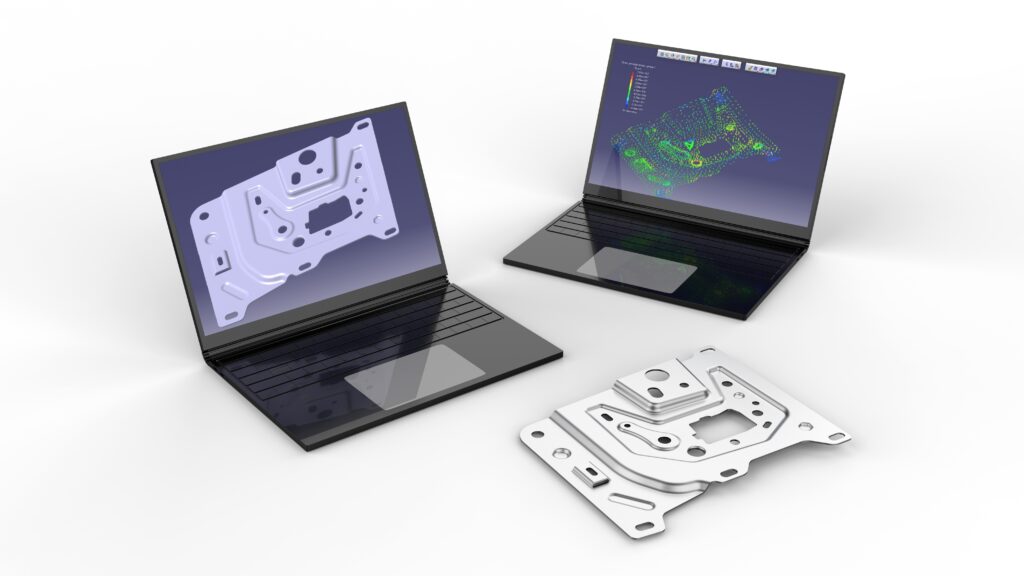

Design Tips for Sheet Metal Fabricating

Design for manufacturability (DFM) is crucial in sheet metal fabrication. It involves designing products in such a way that they are easy and cost-effective to manufacture. Here are some essential tips for optimizing your sheet metal designs:

Importance of Design for Manufacturability (DFM)

- Ease of Production: Designing with manufacturability in mind ensures that the production process is straightforward and efficient, reducing the likelihood of errors and delays.

- Cost Reduction: By considering manufacturing constraints during the design phase, you can minimize material waste, reduce labor costs, and avoid expensive rework.

- Improved Quality: A DFM approach leads to higher quality products by addressing potential issues early in the design process, ensuring that the final product meets all specifications and performance requirements.

Tips for Reducing Costs and Improving Efficiency

- Material Selection: Choose materials that are readily available and cost-effective while still meeting your product’s requirements. For instance, using standard gauge materials can reduce costs and simplify the manufacturing process.

- Simplify Design: Avoid overly complex geometries that require specialized tools or multiple processing steps. Simple, clean designs are easier and cheaper to produce.

- Minimize Part Count: Reducing the number of parts in an assembly can lower manufacturing costs and simplify assembly. Consider combining parts or using multi-functional components.

- Standardize Components: Using standard sizes and shapes for components can reduce tooling costs and improve manufacturing efficiency.

- Design for Assembly (DFA): Ensure that parts are easy to assemble, with features like self-locating tabs and slots that simplify the assembly process and reduce labor time.

Common Design Mistakes to Avoid

- Ignoring Tolerances: Not specifying appropriate tolerances can lead to parts that don’t fit together properly, causing assembly issues and increased costs. Ensure that all dimensions and tolerances are clearly defined.

- Overlooking Bend Radii: Not accounting for proper bend radii can result in cracks or deformations in the metal. Follow standard guidelines for bend radii based on the material thickness.

- Neglecting Hole Placement: Placing holes too close to edges or bends can weaken the material and cause failures. Maintain appropriate distances from edges and bends when designing hole locations.

- Inadequate Draft Angles: For parts requiring stamping or deep drawing, insufficient draft angles can cause issues during the forming process. Ensure that draft angles are adequate for the material and process used.

- Complex Assembly Requirements: Designs that require complex assembly processes can lead to higher costs and longer production times. Aim for designs that simplify assembly and reduce the need for specialized tools or processes.

Premium’s Sheet Metal Fabrication Services

Premium Rapid & Mold offers a comprehensive range of sheet metal fabrication services to meet diverse customer needs. Our services include cutting, forming, joining, and finishing, providing a one-stop solution for all your fabrication requirements.

Overview of Services Offered

- Cutting: We utilize advanced technologies such as laser cutting, plasma cutting, and waterjet cutting to ensure high precision and clean edges for all your parts.

- Forming: Our forming capabilities include bending, rolling, hemming, curling, roll forming, metal spinning, and deep drawing, allowing us to create complex shapes and configurations.

- Joining: We offer various joining methods, including MIG, TIG, and spot welding, riveting, and adhesive bonding, ensuring strong and durable connections.

- Finishing: Our finishing services include powder coating, anodizing, electroplating, polishing, brushing, painting, passivation, and chemical etching, enhancing the appearance and performance of your parts.

Key Advantages

- Experienced Engineers: Our team of skilled engineers has at least eight years of industry experience, ensuring high-quality results and expert guidance throughout the fabrication process.

- One-Stop Service: From sample making to mass production, we provide comprehensive services, streamlining the manufacturing process and reducing communication costs.

- Customer-Centric Approach: We work closely with our clients to understand their specific needs and offer tailored solutions that optimize design, material selection, and production methods.

Conclusion

Sheet metal fabrication is a versatile, durable, and cost-effective solution for manufacturing metal parts. By understanding the various materials and surface finishes available, as well as their applications across different industries, you can make informed decisions for your production needs. Choosing the right partner, like Premium, ensures quality and efficiency in every project.

Importance of Choosing the Right Fabrication Partner

Selecting a reliable and experienced fabrication partner is crucial for the success of your projects. A competent partner will provide expert guidance, high-quality products, and efficient services, ensuring that your production runs smoothly and meets all specifications.

If you’re looking for a trusted partner for your sheet metal fabrication needs, look no further than Premium Rapid & Mold. Contact us today at marketing@prm-mold.com to discuss your project requirements and discover how we can help you achieve your goals with precision and efficiency.