When it comes to sheet metal fabrication, you often have to choose between laser cutting and waterjet cutting. These are two processes that are very important in modern manufacturing, but they are very different in how they work and what they are good for.

Laser cutting is faster and more precise and is good for cutting fine details with high accuracy. It works great with metals and plastics, but it doesn’t work as well with reflective materials or materials that are sensitive to heat. Waterjet cutting is slower, but it can cut thicker materials and materials that don’t do well with heat. The right choice for you depends on the materials you are using and the level of precision you need.

It’s important to use the right cutting process when you do sheet metal fabrication. Laser cutting is great when you need to be very precise and you are making a lot of parts. Waterjet cutting is good when you need to cut a variety of materials and you don’t want to damage the material you are cutting. Let’s look at these two processes in more detail and see what they are good for and what they are not good for.

What Are the Main Differences Between Laser and Waterjet Cutting?

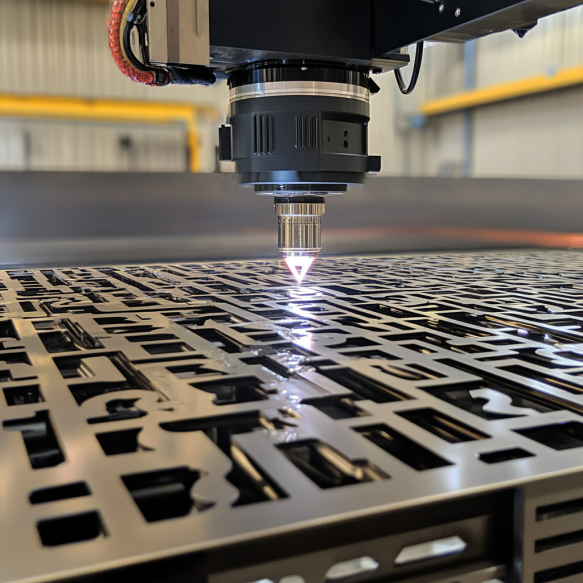

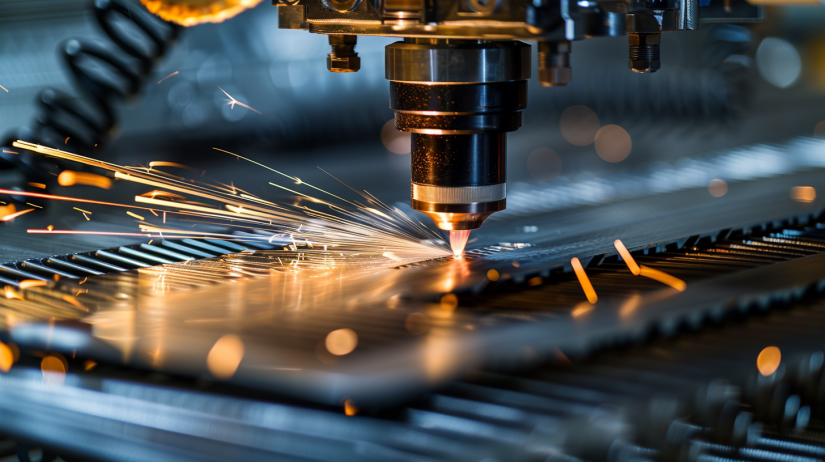

Laser Cutting Process

Laser cutting uses a focused beam of light to melt or vaporize material. Lasers can cut a variety of materials, including metals, plastics, and ceramics. Laser cutting is known for making very fine, detailed cuts with minimal waste. However, you can run into problems with reflective materials because the light energy can reflect off the material, stopping the cutting process. Also, some materials are thermolabile and will break down when you hit them with the laser’s heat.

Waterjet Cutting Process

Waterjet cutting uses a high-pressure stream of water, sometimes mixed with abrasives, to erode the material along the cut line. This process is considered a cold-cutting technique because it doesn’t generate heat, so it doesn’t affect the material’s properties. Waterjet cutting is good for thick materials that are sensitive to heat, such as stone, rubber, and composites. Waterjet cutting can cut a wide range of materials, but it doesn’t work well with tempered glass or diamonds because of the properties of those materials.

Key Differences

The main difference between these two cutting methods is how they remove material. Laser cutting uses heat to melt or vaporize the material, while waterjet cutting uses mechanical force through high-pressure water. These differences affect your material choices, how many parts you are making, and how precise you need to be, which will help you choose the right cutting method.

How Do Cost, Speed, and Precision Compare Between the Two?

Cost Considerations

• Laser Cutting: Lasers are generally cheaper to buy, with machines ranging from 8,000 to 250,000. Laser cutting is cost-effective when you are making a lot of thin parts because it is fast and precise, which means you don’t have to spend a lot of time fixing the parts after you cut them.

• Waterjet Cutting: Waterjets are generally more expensive to buy, with machines ranging from 60,000 to 450,000. However, waterjet cutting is cost-effective when you are cutting thick materials because it can cut a variety of materials without distorting them with heat.

Speed

• Laser Cutting: Lasers are known for cutting fast and can cut up to 1,750 mm per minute, which is great for making a lot of parts. This is especially important when you are cutting materials that are less than 25 mm thick because you need to get them cut quickly.

• Waterjet Cutting: Waterjets are generally slower and cut at speeds around 500 mm per minute. Waterjet cutting is good when you need to preserve the properties of the material you are cutting. Even though it is slower, it is good for cutting materials that can’t take the heat generated by lasers.

Precision

• Laser Cutting: Lasers are known for cutting very accurately and can hold tolerances down to 0.15 mm. This makes them ideal for cutting very detailed patterns and when you need to make exact measurements, such as for electronic components or fine metalwork.

• Waterjet Cutting: Waterjets cut accurately and hold tolerances down to 0.5 mm, which is good when you need to cut materials that can’t take the heat generated by lasers. Even though waterjets are not as accurate as lasers, they are perfect for cutting things where it is more important to keep the material together than to cut it with extreme precision.

How Does Each Method Handle Different Materials?

Material Compatibility

• Laser Cutting: Lasers can cut many different materials, such as metals, plastics, and ceramics. Lasers are good for detailed work in metals like steel and aluminum. You can have trouble with reflective materials like copper and some aluminums because the energy from the laser bounces off the material and doesn’t cut it. You also can’t cut materials that break down when you hit them with heat because this can cause the material to degrade.

• Waterjet Cutting: Waterjets are good for cutting materials that are sensitive to heat, such as stone, rubber, and composites. Waterjet cutting is considered a cold-cutting process, so it doesn’t change the material’s properties, which means it can cut a wider range of materials. This versatility makes waterjet cutting good for cutting many different materials, from soft materials to hard alloys.

What Are the Advantages and Disadvantages of Each Method?

Advantages of Laser Cutting

- Speed and Efficiency: Lasers cut faster than waterjets, especially for materials that are less than 25 mm thick. This means you can cut more parts faster, which saves you money when you are making a lot of parts.

- Precision and Accuracy: Lasers are very accurate and can cut within 0.15 mm, which is great when you need to make very detailed or intricate designs.

- Reduced Waste: Lasers are very precise, so you make less waste, which is good for the environment and saves you money on materials.

- Lower Noise Levels: Lasers are quieter than waterjets, making about 75 dB of noise compared to 90 dB for waterjets.

Disadvantages of Laser Cutting

- Thickness Limitations: Lasers can’t cut materials that are much thicker than about 30 mm, while waterjets can cut materials that are up to 300 mm thick.

- Fume Emission: Lasers make smoke that is bad for you to breathe, so you need to have a good ventilation system to keep the air clean.

Advantages of Waterjet Cutting

• Material Versatility: Waterjets can cut materials up to 300 mm thick without changing the material’s properties. Waterjets can cut many different materials, from soft rubber to hard metals.

• Cold Cutting: Because waterjets don’t make heat, they don’t change the material’s properties, so you don’t have to worry about the material changing.

• Good for the Environment: Waterjets don’t make smoke, so they are better for cutting materials that make bad smoke when you heat them.

Disadvantages of Waterjet Cutting

- Slower Cutting Speed: Waterjets are slower than lasers, which can slow down how fast you can make parts when you are making a lot of them.

- Waste Management: Waterjets make both liquid and solid waste that you have to clean up, which can cost you more money to run the machine.

Cutting Edge Changes

Hybrid Cutting Systems

- Integration of Strengths: • Hybrid systems combine lasers and waterjets, giving you the precision of a laser with the versatility of a waterjet. These systems allow you to switch from one method to the other, depending on the material you are cutting. This gives you the flexibility to cut a variety of materials efficiently, which is great for complicated projects.

Laser-Assisted Waterjet Cutting

- Enhanced Cutting Process: This new way of cutting combines lasers with waterjets. The laser heats the material, which makes it easier for the waterjet to cut through thick sections of material with more precision. This process helps you cut faster and makes the edges of the material smoother, especially when you are cutting materials like ceramics and composites.

Industry Innovations and Applications

Smart Manufacturing and IoT Integration

- Real-Time Optimization: People are starting to use both cutting technologies in smart manufacturing environments with the Internet of Things (IoT). They are using real-time data monitoring and machine learning to make the machine cut better, know when it needs to be fixed, and make more stuff faster, which helps them do the things they want to do with Industry 4.0 and make the machine do what they want it to do.

Customizable Cutting Parameters

- Advanced Software Solutions: People are using software to change how these machines cut. You can adjust the settings for each material and part, which makes the machine cut better and makes the parts better. This customization helps you make less waste and make more stuff faster, which saves you money when you are making a prototype or custom parts.

Material-Specific Considerations

Laser Cutting for High Reflectivity Metals

- Specialized Techniques: People use special techniques like moving the beam around and changing how often it hits the metal to make the machine cut reflective metals like gold and silver. This helps keep the beam from bouncing off the metal and makes the machine cut better, which means you can use it to cut a lot of different things.

Waterjet Cutting of Advanced Ceramics

- Preserving Material Integrity: Waterjets are good for cutting advanced ceramics used in electronics, airplanes, and medical equipment. Waterjets don’t make heat, so they don’t hurt the ceramic, which helps you make parts that are accurate and strong, which is important when you are making things for high-tech industries.

Cost Optimization and Resource Management

Energy Efficiency Improvements

- Modern Systems: Lasers have new features to help save energy, like turning off when you aren’t using them and making the beam better. This helps you save energy and do more stuff, which is good for the environment and saves you money in the long run.

Abrasive Material Innovations

- Efficient Cutting: People made new things to put in waterjets to help them cut better. People use man-made stuff to get the same thing every time and to make the nozzle last longer, which saves you money and helps you cut better.

What Are the Industry-Specific Applications of Laser and Waterjet Cutting?

Aerospace Industry

- Laser Cutting: People use lasers to cut parts like turbine blades and other things that need to be very accurate and make very little waste. Lasers cut fast and make the airplane parts faster, which helps you make the airplane faster.

- Waterjet Cutting: Waterjets are good for cutting things like wings and airplane parts that are made out of materials that don’t do well with heat. Waterjets don’t make heat, so they don’t change the material, which is important when you are making airplane parts.

Automotive Industry

- Laser Cutting: People use lasers to make parts like car doors, small parts, and custom parts that need to be very accurate and made fast. Lasers help you make parts faster and save money, which is why they are good for making a lot of parts fast and making them cheap.

- Waterjet Cutting: Waterjets are good for making parts that are hard to make and need to be made fast, like engine parts and parts for inside the car. Waterjets can cut many different materials, which is why they are good for making parts for cars.

Construction and Architecture

- Laser Cutting: People use lasers to make things like metal decorations, metal walls, and custom things that need to be perfect. Lasers can cut very small and detailed things, which is good for making things that look nice.

- Waterjet Cutting: Waterjets are good for cutting things like stone and tile for buildings, which need to be cut without heat. Waterjets can cut many different materials, which is why they are good for making things that need to fit together perfectly.

Medical Equipment Manufacturing

- Laser Cutting: People use lasers to make small parts for medical devices that need to be very accurate and exact. Lasers help you make the same thing every time, which is important when you are making things for sick people or machines that help them.

- Waterjet Cutting: Waterjets are good for cutting things like plastic and rubber for medical devices that can’t be cut with heat. Waterjets don’t make heat, so they don’t change the material, which is important when you are making things for sick people or machines that help them.

Electronics Industry

- Laser Cutting: People use lasers to make small parts for electronics that need to be very accurate and fast. Lasers help you make parts fast and make a lot of them, which is important in the electronics industry.

- Waterjet Cutting: Waterjets are good for cutting things like plastic and rubber for electronics that can’t be cut with heat. Waterjets can cut many different materials, which is why they are good for making parts for electronics.

FAQ: Laser Cutting vs. Waterjet Cutting

What do you need to do to be safe when you use lasers?

Wear glasses and make sure the air is clean so you don’t get sick. Keep the machine clean and running right so you don’t break it.

Can waterjets cut things like airplane wings and car parts?

Yes, waterjets are good for cutting things like airplane wings and car parts because they don’t make heat, which can change the material. This is important when you are cutting things that need to be very accurate and strong.

What projects are good for using both lasers and waterjets?

Projects that need to be cut very small and very thick or made out of materials that don’t do well with heat are good for lasers and waterjets. Using both helps you make things faster and better, which is good when you need to make a lot of things.

How do lasers and waterjets help you make less waste?

Lasers make very small cuts and put the pieces close together, which means you make less waste. Waterjets don’t make heat, so the material doesn’t change when you cut it and you don’t have to throw it away. Both ways of cutting help you make things with less waste, which is good for the environment and saves you money.

What new things are making lasers and waterjets better?

Lasers are better because they use fiber and cut faster, which helps you make more stuff and not have to fix the machine as much. Waterjets are better because they use new things to cut with and make the nozzle last longer, which helps you make more stuff and saves you money.

Conclusion

Selecting the appropriate cutting technology is crucial for achieving optimal results in sheet metal fabrication. Laser cutting provides unmatched precision and efficiency for high-volume production and detailed designs. Waterjet cutting excels in versatility, capable of slicing through diverse materials without compromising structural integrity. Let’s explore these technologies further, uncovering their advantages, limitations, and industry-specific applications.