Sheet Metal Fabrication Factory

Transform Your Designs into Reality: Expert Sheet Metal Fabrication for Your Business's Next Leap Forward.

The Sheet Metal Fabrication Services Premium offers you

Elevate Your Business Precision: Premium’s Sheet Metal Fabrication Services. Tailored to your unique needs, our expert team blends innovation with mastery in metalwork, delivering exceptional quality that propels your projects forward. Experience the fusion of technology and skill that transforms your vision into reality.

Laser Cutting

Laser cutting at Premium is synonymous with precision and versatility. Harnessing advanced laser technology, we execute intricate cuts with impeccable accuracy. Ideal for custom designs, prototypes, and complex geometries, our laser cutting service offers unmatched precision, speed, and flexibility to meet diverse industry requirements.

Sheet Metal Stamping

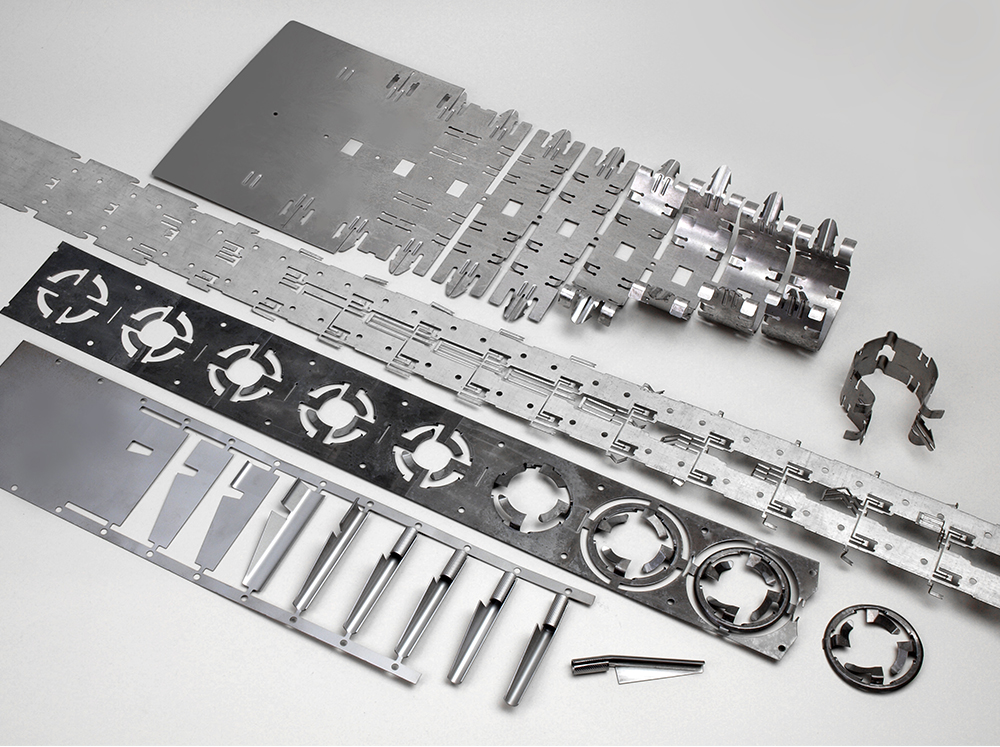

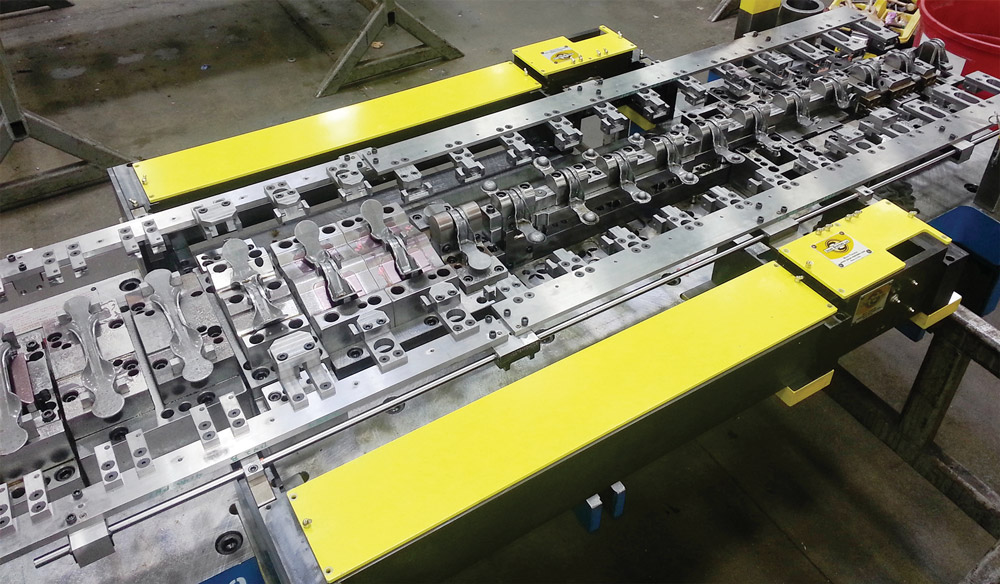

Premium’s sheet metal stamping offers precision and efficiency, ideal for large-scale production. Utilizing state-of-the-art presses, we ensure uniformity and accuracy in every product, from automotive parts to intricate electronic components. Our expertise guarantees minimal waste and maximum cost-effectiveness, making us a leader in high-volume stamping solutions.

Sheet Metal Punching

In sheet metal punching, Premium excels with unparalleled accuracy. Our advanced machinery and skilled technicians craft intricate designs with precision. This service is perfect for creating complex patterns, ventilation grilles, and detailed component features. We balance speed with precision, ensuring rapid turnaround without compromising on quality.

Sheet Metal Welding

At Premium, our welding services merge durability with finesse. Specializing in various welding techniques, we cater to diverse industry needs, from heavy machinery to delicate electronic enclosures. Our expert welders ensure strong, clean, and aesthetically pleasing joints, upholding the highest standards of quality and safety.

Sheet Metal Assembly

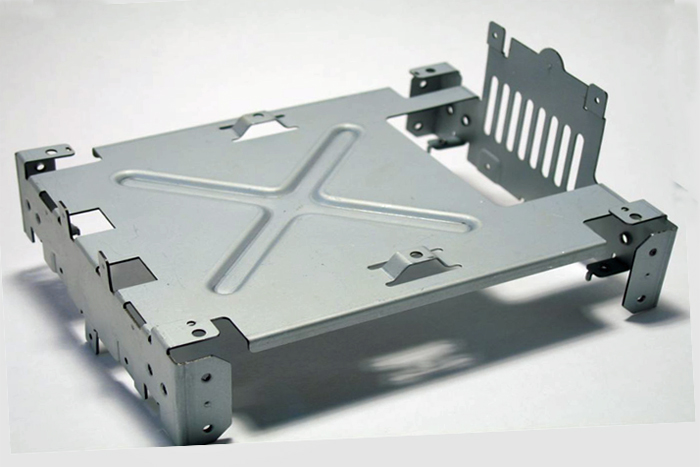

Premium’s assembly services integrate various components into a cohesive and functional final product. Our meticulous approach ensures that each part fits perfectly, reflecting our commitment to quality and precision. From small devices to large structural elements, we offer comprehensive solutions that encompass design, fabrication, and assembly.

Your Extensive Sheet Metal Fabrication Solution Provider in China

At Premium, we understand the complexities of your sheet metal fabrication needs. Specializing in precise, customized solutions, we offer a diverse range of services to meet your unique project requirements. From intricate designs to robust assemblies, our expert team in China ensures your vision is realized with excellence and efficiency.

Rapid Prototyping to Production Scaling: Quickly move from initial prototypes to large-scale production with our adaptable infrastructure, ensuring smooth progression from design to market.

Complex Sheet Metal Forming Expertise: Specializing in intricate and complex shapes, our team utilizes advanced equipment to masterfully craft challenging sheet metal designs.

Customized Metal Joining Solutions: Offering a range of innovative metal joining methods, including adhesive bonding, riveting, and laser welding, tailored to fit your project’s specific requirements.

High-Precision Bending and Folding: Utilizing top-tier press brakes and skilled technicians, we deliver highly precise bending and folding services, meeting exacting quality standards.

Material Versatility and Expertise: Expert guidance in selecting the perfect material, from stainless steel to exotic alloys, focusing on strength, weight, and corrosion resistance for your unique project needs.

Effortlessly Customize Your Sheet Metal Fabrication Projects

Experience effortless customization in sheet metal fabrication with Premium. Our refined processes and dedicated team ensure your project’s smooth journey from concept to precision production, eliminating common complications and guiding you through every step with our efficient and streamlined approach.

-1024x683.jpg)

Streamlined Project Management: Premium ensures a hassle-free experience by assigning dedicated project managers, streamlining communication and coordination for your sheet metal fabrication needs.

-1024x683.jpg)

Custom Design Support: Our skilled engineers collaborate closely with you, transforming your ideas into viable designs, making customization in sheet metal fabrication effortless and precise.

Rapid Prototyping Services: Quickly turn concepts into reality with Premium’s rapid prototyping, offering a glimpse of the final product and accelerating design validation.

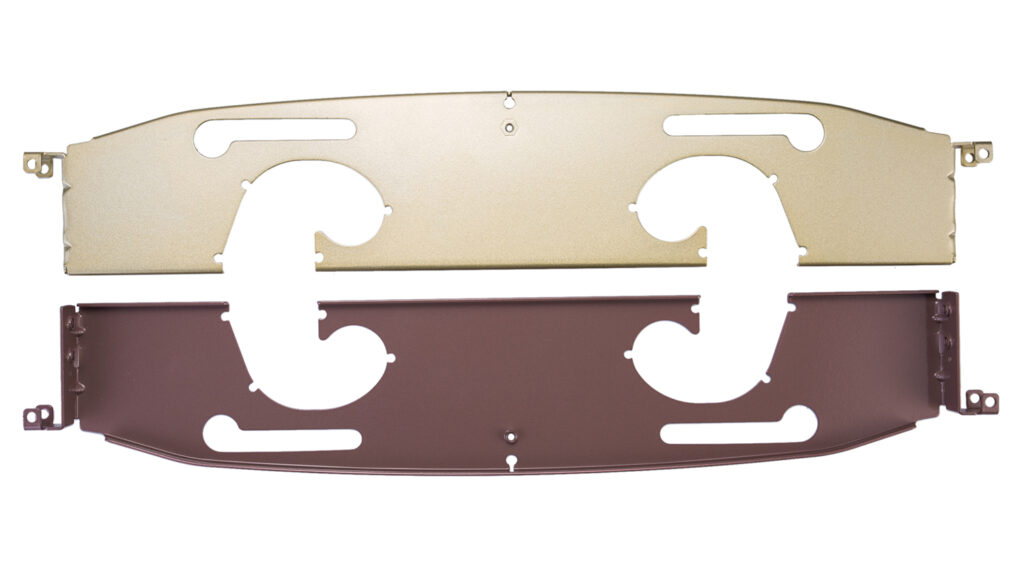

Versatile Finishing Options: Choose from a variety of finishing techniques like powder coating or anodizing to enhance the appearance and durability of your customized products.

Why Choose Sheet Metal Fabrication Service from Premium Mold?

Empower your business with Premium Rapid’s sheet metal fabrication services. We blend precision, speed, and innovation to transform your metalwork projects, ensuring results that not only meet but exceed your expectations.

1.Scalable Production Capabilities: From prototyping to high-volume production, adapt seamlessly with our scalable fabrication capabilities.

2.Real-Time Project Tracking: Stay informed with our real-time updates, offering transparency and control over your project’s progress.

3.Cost-Effective Solutions: Maximize your budget with our competitive pricing, offering high-quality fabrication without the premium cost.

4.Swift Lead Times: Experience our rapid turnaround as fast as 5 days, vital for meeting tight deadlines without compromising on quality or accuracy.

5.Seamless Integration and Assembly: We don’t just fabricate; we assemble and integrate, providing a comprehensive service that simplifies your supply chain.

FAQs About Sheet Metal Fabrication Services

We’ve compiled the most frequently asked questions about Premium’s Sheet Metal Fabrication services for your convenience. However, should you have any additional questions, please don’t hesitate to contact us.

Sheet metal fabrication is generally cost-effective for producing metal parts, especially for medium to large-scale production runs. Affordability is influenced by factors like material choice, complexity of design, production volume, and the efficiency of the fabrication process. Advanced techniques can further optimize costs and turnaround times.

Common materials include aluminum, stainless steel, mild steel, copper, brass, and various alloys. Each material offers unique properties like strength, corrosion resistance, and weight, making them suitable for specific applications and industries.

Industries like automotive, aerospace, construction, electronics, and medical devices heavily rely on sheet metal fabrication. It's crucial for creating components such as vehicle panels, aircraft skins, building cladding, electronic enclosures, and surgical instruments.

Absolutely. Modern sheet metal fabrication uses advanced technologies like CNC machinery and CAD/CAM software, enabling the creation of high-precision parts and complex geometries with tight tolerances.

Stamping is a specific process within sheet metal fabrication that involves placing flat sheet metal in either blank or coil form into a stamping press. Fabrication, however, is a broader term encompassing various processes including stamping, cutting, bending, and assembling.

Limitations can include the properties of the material being used, the complexity of the design, and the precision of the equipment. Thicker materials and more intricate designs may require specialized machinery and can increase production time and cost.

Thickness affects the bending process, cut quality, and the strength of the final product. Thicker metals require more force to bend and may limit the sharpness of bends. Thinner metals are easier to manipulate but may lack structural strength.

Yes, Premium provides prototyping services to validate design, functionality, and manufacturability before committing to large-scale production, ensuring optimal results and client satisfaction.

Premium accommodates a wide range of order sizes, including small batches, without stringent minimum order requirements, focusing on client needs and project specifics.

Turnaround times depend on project complexity, material availability, and order volume. Premium aims for efficiency, typically completing standard projects within 2-5 weeks.

Premium offers ongoing technical support post-delivery, ensuring clients have assistance with any issues or questions regarding their fabricated parts.

Premium holds ISO and IATF16949 certifications, ensuring adherence to international standards in quality management and manufacturing processes.

Premium can accommodate rush orders, offering expedited services for time-sensitive projects while maintaining quality and precision.

Premium offers diverse finishes for sheet metal fabrication, including powder coating for durability, anodizing for corrosion resistance, electroplating for enhanced aesthetics, painting for color variety, bead blasting for texture, passivation for stainless steel, galvanizing for outdoor resilience, and polishing for a sleek finish.

Premium Fabrication: Excellence in Every Detail

Explore Premium's comprehensive sheet metal fabrication journey, from process to package. Experience our dedication to precision, quality, and innovation, showcased in every aspect of our state-of-the-art workshop, superior finishes, stringent quality checks, secure packaging, and industry-leading certifications.

Premium’s production process blends cutting-edge technology with skilled craftsmanship. We specialize in advanced techniques like laser cutting, precision bending, and intricate assembly. Our process is optimized for efficiency, ensuring fast turnaround times without compromising on the intricacy and accuracy of your custom sheet metal projects.

Step into Premium’s workshop, a hub of technological innovation and expertise. Equipped with the latest machinery and overseen by experienced technicians, our workshop embodies our commitment to excellence. We maintain a clean, organized, and safe environment, conducive to producing high-quality sheet metal components.

At Premium, we offer a variety of surface finishes, enhancing both functionality and aesthetics. Options include powder coating for durability, anodizing for wear resistance, electroplating for visual appeal, and bead blasting for a uniform texture. Each finish is meticulously applied to meet your specific requirements.

Quality is paramount at Premium. Our rigorous inspection process employs advanced measurement tools and techniques, ensuring every product adheres to the highest standards. From material verification to final inspection, our dedicated quality control team scrutinizes every detail for dimensional accuracy and flawless execution.

Premium ensures your sheet metal products are as secure in transit as they are impeccable in design. Our bespoke packaging solutions, tailored to each project, protect against all odds. Your products arrive safe, sound, and ready to impress, no matter the distance.

Our certifications speak for our commitment to quality. Premium’s adherence to ISO 9001 and other industry standards means you’re partnering with a team that’s globally recognized for manufacturing excellence. We bring you peace of mind, knowing your projects meet the highest quality benchmarks.

Navigating Your Sheet Metal Fabrication Services Purchase: The Comprehensive Guide

Embark on a journey through Premium’s Sheet Metal Fabrication Services. Whether for intricate designs or mass production, our guide illuminates every facet of our top-quality offerings. Let us streamline and enrich your sourcing experience, ensuring efficiency and insight at every step of your Sheet Metal project.

Table of Contents

What is Sheet Metal Fabrication: A Comprehensive Overview

Sheet metal fabrication is a big deal in manufacturing. It’s the process of making stuff out of thin sheets of metal. It’s a great way to make things because it’s pretty precise, it’s versatile, and it’s cost-effective. That’s why people love it. You see it used a lot in cars, planes, medical stuff, and electronics.

What is Sheet Metal Fabrication?

Sheet metal fabrication is the process of taking flat pieces of metal and turning them into stuff. You cut it, you bend it, you form it, and you assemble it. The goal is to make something that’s the right shape, the right size, and the right configuration for whatever you need it to do.

Key Processes in Sheet Metal Fabrication

Cutting

Laser Cutting: You use a big laser to cut out the stuff. It’s great for making really detailed things.

Waterjet Cutting: You use a bunch of water to cut out the stuff. It’s good for stuff that can’t get hot.

Plasma Cutting: You use a bunch of electricity to cut out the stuff. It’s great for cutting out really thick stuff really fast.

Forming

Bending: This is when you use a big press to bend the metal into U-shapes, V-shapes, and channels. You need to do this to make the metal do what you want.

Stamping: This is when you press the metal into a die and it makes the metal do what you want.

Roll Forming: This is when you take a long strip of metal and bend it until it looks like what you want it to look like.

Joining

Welding: You melt the metal together with other metal so it stays together forever. MIG and TIG are two common types of welding.

Riveting: You use little rivets to keep the stuff together. It’s used a lot in planes.

Fastening: You use screws, bolts, and PEM inserts to keep the stuff together.

Finishing

Powder Coating: You put a thick layer of plastic on the metal. It makes the metal look good and it keeps it from getting scratched.

Anodizing: You make the metal so it won’t rust and you make it look pretty.

Plating: You put a thin layer of metal on the metal. It makes the metal look good and it makes it last a long time.

Materials Used in Sheet Metal Fabrication

People use a few different types of metal in sheet metal fabrication. They use:

Aluminum: It’s light and it doesn’t rust. It’s used a lot in planes and cars.

Steel: It’s tough and it lasts forever. It’s used in buildings and big machines.

Stainless Steel: It doesn’t rust and it’s used in medical stuff and kitchens.

Copper: It conducts electricity and it’s used in electronics.

Advantages of Sheet Metal Fabrication

Sheet metal fabrication is great because:

You can make almost anything out of metal.

Metal stuff is really strong.

You can make metal stuff really precise.

You can make a lot of metal stuff and it doesn’t cost that much.

Applications of Sheet Metal Fabrication

You see sheet metal fabrication used in:

Cars: They make the bodies, the engines, and the pipes.

Planes: They make the wings and the tails.

Medical Stuff: They make the parts for the machines that keep you alive.

Electronics: They make the boxes and the cases.

Buildings: They make the roofs, the air conditioners, and the frames.

Quality Control in Sheet Metal Fabrication

Quality control is super important in sheet metal fabrication. You have to:

Check the stuff all the time to make sure it’s the right size and it’s not messed up.

Use really fancy machines to make sure you cut the stuff the right way and you bend the stuff the right way.

Test the metal to make sure it’s the right metal and it won’t break.

Conclusion

Sheet metal fabrication is a big deal in manufacturing. It’s great because you can make a lot of stuff. By knowing all the different ways to do it, the different metals to use, and all the stuff you can make, you can use sheet metal fabrication to make great stuff. Whether you’re making stuff for cars, planes, medical stuff, or electronics, sheet metal fabrication is a big deal.

The Manufacturing Process of Sheet Metal Fabrication

Sheet metal fabrication is a core manufacturing process that converts flat metal sheets into functional products and components. This process is widely used across industries like automotive, aerospace, electronics, and construction. The common steps in sheet metal fabrication involve cutting, forming, joining, and finishing metal parts. Here is an overview of the key stages in this process:

1. Material Selection

The process begins with selecting the appropriate material based on the product’s function, cost, and performance requirements. Common materials include aluminum, steel, stainless steel, and copper. The choice depends on factors such as corrosion resistance, weight, strength, and machinability. For

example, stainless steel is selected for its corrosion resistance in harsh environments, while aluminum is chosen for its lightweight properties in aerospace applications.

2. Cutting

Cutting is the first mechanical step in sheet metal fabrication. The metal sheet is cut into the desired shape and size using techniques like:

- Laser Cutting: Uses a focused laser beam to cut metal with high precision and speed. It’s commonly used for intricate designs and small tolerances.

- Shearing: Involves using a machine to make straight cuts in the metal by applying a shearing force.

- Plasma Cutting: Utilizes an ionized gas (plasma) to cut through thicker metal sheets, especially steel.

- Waterjet Cutting: Involves a high-pressure stream of water mixed with an abrasive substance to cut metal without generating heat, which helps preserve the integrity of the material.

Each method offers distinct advantages based on the type of material, thickness, and complexity of the part.

3. Forming

Forming is the process of bending or shaping the flat sheet metal into three-dimensional structures. This is typically achieved using press brakes, rollers, or dies. The forming process involves:

- Bending: Metal is bent into angles using a press brake, which applies force to create precise bends in the sheet metal. This is useful for creating components like brackets or enclosures.

- Stamping: A process that uses a die to press the sheet metal into a specific shape. It is often used for mass-producing parts with consistent shapes.

- Roll Forming: In this method, the metal sheet passes through a series of rollers that gradually shape it into the desired cross-section, often used for long components like structural supports.

4. Punching

Punching is the process of creating holes, slots, or shapes in the metal sheet using a punch press. This technique is used when repeated, precise holes or cutouts are needed, such as in the production of perforated metal sheets or enclosures with ventilation holes. Punching is highly efficient for medium to high-volume production runs.

5. Joining

After cutting and forming, the individual components need to be assembled. Common joining techniques in sheet metal fabrication include:

- Welding: A method where two metal parts are fused together using heat. MIG (Metal Inert Gas) welding and TIG (Tungsten Inert Gas) welding are two common types used for sheet metal. MIG welding is faster and suitable for thicker materials, while TIG welding is used for precision and thinner metals.

- Riveting: Mechanical fasteners are used to join two or more pieces of metal. This method is often employed when welding is not suitable, such as when joining dissimilar metals or where heat-sensitive components are involved.

- Screws and Bolts: Fasteners are used for non-permanent joints, allowing for disassembly and reassembly when needed.

6. Surface Treatment

Surface treatment enhances the aesthetics, durability, and corrosion resistance of sheet metal parts. Common surface treatments include:

- Powder Coating: A dry powder is applied electrostatically to the surface and cured under heat to form a protective, decorative layer. This method provides a tough, scratch-resistant finish suitable for outdoor and industrial applications.

- Anodizing: This electrochemical process adds a protective oxide layer to aluminum, increasing corrosion resistance and offering a variety of color finishes.

- Plating: A thin layer of metal, such as zinc or chrome, is added to improve corrosion resistance and durability.

These treatments are often critical in industries such as automotive and electronics, where durability and appearance are key.

7. Assembly

Once all the individual parts have been fabricated and treated, they are assembled into final products. Assembly may involve installing inserts, mounting hardware, or assembling multiple parts into a complex structure. For example, metal frames may be assembled into enclosures for electrical components.

8. Quality Control

Quality control is a vital part of sheet metal fabrication, ensuring that the parts meet design specifications and industry standards. Inspections are conducted throughout the process, including dimensional checks, weld integrity tests, and surface finish inspections. Advanced techniques like CNC (Computer Numerical Control) are used to ensure precise and consistent production.

9. Final Inspection and Delivery

Before the parts are shipped to the customer, a final inspection is performed to verify that all dimensions, finishes, and assemblies meet the required standards. The parts are then packaged securely to prevent damage during transport. Special care is taken to label and organize parts correctly, particularly for large projects involving multiple components.

Sheet metal fabrication is a highly efficient and flexible process, capable of producing everything from small, intricate components to large, structural elements. By mastering these core processes, manufacturers ensure high-quality, reliable products that meet the specific needs of industries like automotive, aerospace, and electronics.

The Materials of Modern Sheet Metal Fabrication

The versatility of sheet metal fabrication lies in its adaptability to a wide array of materials, each bringing unique properties to the manufacturing table. As we delve into this sector, understanding the material options is crucial for both novices and seasoned professionals in the industry.

Aluminum: Renowned for its lightweight yet strong nature, aluminum is a popular choice in sheet metal fabrication. It’s preferred for its exceptional corrosion resistance and excellent workability, making it ideal for aerospace, automotive, and consumer electronics.

Stainless Steel: Valued for its strength and durability, stainless steel is a go-to material for applications requiring resistance to heat and corrosion. Its widespread

use in kitchen appliances, medical equipment, and industrial machinery is testament to its reliability.

Mild Steel: Known for its affordability and strength, mild steel is commonly used where cost-effectiveness is a priority. It’s often found in automotive parts, construction materials, and various everyday tools.

Copper: With superior electrical conductivity, copper is essential in electrical components. Its thermal conductivity also makes it suitable for heat exchangers and radiators.

Brass: A blend of copper and zinc, brass is known for its acoustic properties, corrosion resistance, and aesthetic appeal, making it a favorite for decorative items, musical instruments, and fittings.

Galvanized Steel: Known for its enhanced corrosion resistance due to a zinc coating, galvanized steel is widely used in outdoor applications, HVAC systems, and automotive parts. Its protective layer makes it suitable for harsher environments.

Titanium: Prized for its high strength-to-weight ratio and corrosion resistance, titanium is a premium choice in aerospace, medical implants, and high-performance automotive applications. Its exceptional durability makes it ideal for long-term, high-stress uses.

Bronze: An alloy primarily consisting of copper and tin, bronze is known for its wear resistance and strength. It’s often used in bearings, bushings, and gears, especially where friction and wear are significant concerns.

Nickel Alloys: These are crucial in high-temperature, high-stress environments, such as jet engines and chemical processing equipment. They maintain strength and resist corrosion even in extreme conditions.

Zinc: Often used in plating and coating for corrosion protection, zinc is also used in its sheet form for roofing, panels, and decorative elements. It offers moderate strength and is relatively easy to form.

Magnesium Alloy: Known for being the lightest structural metal, magnesium alloys are increasingly used in automotive and aerospace applications to reduce weight without sacrificing strength.

Each material choice in sheet metal fabrication is guided by the specific requirements of the project, taking into account factors like strength, malleability, conductivity, and environmental resistance. The choice directly influences the project’s cost, durability, and overall functionality, underscoring the material’s critical role in the fabrication process.

Basic Guidelines for Sheet Metal Fabrication

Sheet metal fabrication stands as a beacon of modern manufacturing, skillfully transforming metal sheets into functional, diverse components. This comprehensive guide traverses the journey from initial design to final product, providing insights into the meticulous process and the inherent capabilities and constraints of this pivotal industry.

Design for Manufacturability:

- Design parts for streamlined fabrication, focusing on efficient use of materials and reducing fabrication steps.

- Account for factors like ease of assembly, reducing waste, and optimizing sheet utilization.

- Utilize CAD software to simulate fabrication processes, enabling adjustments before actual production, thus saving time and resources.

-1024x683.jpg)

- Focus on designing parts with manufacturability in mind. This includes avoiding overly complex shapes that are difficult to fabricate.

- Ensure designs account for the bending radius, material stretch, and potential deformation.

Material Selection:

- Carefully choose materials based on project requirements, considering factors like strength, weight, corrosion resistance, and cost.

Common materials include aluminum, stainless steel, and copper, each offering unique advantages and suitability for different applications.

Surface Finishing:

- Surface finishing enhances both aesthetic appeal and functionality of sheet metal products.

- Techniques include powder coating, anodizing, and electroplating, providing corrosion resistance and unique visual finishes.

- Selection of finishing depends on the application, with certain finishes adding to the material’s durability and others purely for visual enhancement.

Tolerances and Dimensions:

- Emphasis on Accuracy: Sheet metal fabrication demands precise tolerances and dimensions for each component, ensuring fit and functionality.

Tolerance Ranges: Typically, tolerances range from ±0.1 mm to ±0.5 mm. The exact figures depend on the project’s complexity and the machinery used.

Dimensional Consistency: Utilizing precise measuring tools and techniques is crucial to maintain consistent dimensions throughout the fabrication process.

Joining Techniques:

- Employ diverse joining methods like welding, riveting, and adhesive bonding to assemble complex structures.

- Each technique is chosen based on the material type, intended use, and desired strength of the final assembly.

- Advanced laser welding offers precision in high-volume productions, ensuring durability and integrity of joints.

Type of Sheet Metal Fabrication:

- Stamping: Ideal for high-volume production, stamping presses the metal into a die to form the desired shape.

- Bending: Involves creating V, U, or channel shapes in sheet metal, using brake presses.

- Laser Cutting: Best for complex, precise cuts without physical contact with the metal.

- Welding: Used for joining two or more pieces of metal together with high strength.

Punching: Involves creating holes or shapes in the metal by pressing a punch into a die containing the metal sheet.

Advantages of Sheet Metal Fabrication:

- Versatility in material selection allows for a wide range of applications.

- Cost-effectiveness for both short-run and mass production.

High strength-to-weight ratio, especially with materials like aluminum and stainless steel.

Limitations and Challenges:

- Material limitations: Certain metals might not be suitable for complex shapes or might not offer the desired aesthetic.

- Precision issues: Achieving extremely tight tolerances can be challenging and costly.

- Design restrictions: Some design elements may not be feasible due to the limitations of bending and cutting technologies.

Sheet metal fabrication is essential in modern manufacturing, adaptable to a wide range of project requirements. Its ability to mold to different applications, from small custom parts to large industrial components, illustrates its irreplaceable role.

Diverse Applications of Sheet Metal Fabrication in Defense

Adaptive Designs for Unmanned Systems: Sheet metal fabrication plays a pivotal role in the development of unmanned systems, including drones and autonomous vehicles. The adaptability of sheet metal allows for the creation of lightweight, yet robust structures that are essential for the efficiency and maneuverability of these systems.

High-Security Communication Equipment Enclosures: The fabrication process is instrumental in creating enclosures for sensitive communication equipment. These enclosures are designed to shield against electromagnetic interference (EMI) and ensure secure, uninterrupted communication channels, which are crucial in defense operations.

Advanced Thermal Management Components: With electronic systems playing a crucial role in modern military equipment, effective thermal management is paramount. Sheet metal fabrication facilitates the creation of heat sinks, enclosures, and other components that are critical for dissipating heat and maintaining the optimal functioning of electronic systems.

Ballistic and Blast Protection Enhancements: The fabrication process is key to developing ballistic and blast protection elements for military vehicles and structures. Utilizing high-strength, impact-resistant metals, these components provide essential protection to personnel and equipment in hostile environments.

Integration with Composite Materials: The combination of sheet metal with advanced composite materials leads to the development of hybrid structures that offer superior strength-to-weight ratios. This integration is particularly beneficial in aerospace applications, where weight reduction without compromising strength is vital.

Specialized Tooling for Maintenance and Repair: Beyond component fabrication, the process also involves creating specialized tooling and equipment for the maintenance and repair of military hardware. This tooling is designed to handle the unique requirements and specifications of military equipment.

Ergonomic Designs for Personnel Safety: Emphasis is also placed on the ergonomic design of sheet metal components to ensure the safety and comfort of military personnel. This includes the development of user-friendly interfaces, safe access panels, and protective coverings in military machinery and workspaces.

Stealth Technology Integration: In the realm of stealth technology, sheet metal fabrication is used to create components with specific geometries and surface treatments that minimize radar and infrared signatures, a crucial aspect in modern warfare.

In essence, sheet metal fabrication for defense applications extends far beyond the creation of simple components. It involves a multifaceted approach that encompasses advanced technologies, materials science, and an acute understanding of military needs, reflecting its indispensable role in the defense sector.

Customization in Sheet Metal Fabrication: Meeting Unique Client Demands

In the dynamic world of sheet metal fabrication, customization is the key to meeting diverse and specific client requirements. This article delves into the facets of customized sheet metal fabrication, highlighting its significance and the capacity to cater to unique demands.

Understanding Client Specifications: The process starts with an in-depth analysis of client needs. Detailed consultations are held to understand the precise requirements, whether it’s for aerospace precision or automotive durability.

Design Flexibility: Utilizing advanced CAD software, designs are tailored to exact client specifications. This flexibility allows for modifications and adaptations, ensuring that each project uniquely aligns with client objectives.

Material Selection: Custom fabrication involves choosing from a wide array of materials like lightweight aluminum, corrosion-resistant stainless steel, or robust carbon steel. Each material is selected based on its specific properties, aligning with the functional and aesthetic needs of the project.

Adaptable Production Processes: Customization in sheet metal fabrication is characterized by adaptable production processes. Techniques such as CNC machining, laser cutting, and precision forming are adjusted to suit the unique contours and specifications of each project.

Rapid Prototyping for Feedback: Rapid prototyping plays a critical role in customization. It allows clients to review and provide feedback on a physical model before full-scale production, ensuring the end product aligns perfectly with their vision.

Custom Tooling for Unique Projects: For projects requiring unique shapes and components, custom tooling can be developed. This ensures even the most non-standard designs can be accurately and efficiently fabricated.

Collaborative Design Approach: Custom fabrication often involves a collaborative approach between the fabricator and client. This synergy in design and planning phases ensures that the client’s vision is accurately translated into the final product.

Stringent Quality Control: Customized projects undergo stringent quality control measures. Each component is meticulously inspected to ensure it adheres to the desired specifications, functionality, and quality standards.

In essence, customization in sheet metal fabrication is not just a service but a commitment to aligning manufacturing expertise with the unique visions of clients, ensuring every project is not just completed, but perfected.

Customization in sheet metal fabrication isn’t just about shaping metal; it’s about understanding client visions and transforming them into tangible, high-quality products. It’s the blend of technical prowess, innovative thinking, and a commitment to client satisfaction that makes customized fabrication a cornerstone in modern manufacturing.

Sheet Metal Fabrication in the Automotive Industry

The automotive industry’s relentless pursuit of innovation significantly relies on advancements in sheet metal fabrication. Here’s a glimpse into how these developments are driving automotive progress.

Emphasis on Lightweight Materials: A key shift is the use of aluminum and high-strength steel. These materials play a pivotal role in reducing vehicle weight, crucial for boosting fuel efficiency and lowering emissions.

Adaptation to Electric Vehicle Needs: The surge in electric vehicle production has steered sheet metal fabrication towards accommodating unique components like battery housings and motor parts. Precision in these fabrications is vital for the safety and efficiency of electric vehicles.

Utilizing Cutting-Edge Techniques: Modern vehicles benefit from advanced methods like 3D laser cutting and hydroforming. These enable the creation of more complex parts, fitting the innovative designs of contemporary vehicles.

Customization and Design Flexibility: The rise in demand for customized vehicles has led to the adoption of flexible fabrication solutions. Advances in CAD/CAM technologies facilitate the creation of intricate, tailor-made designs.

Integration with Automation: Automation in sheet metal fabrication is revolutionizing the industry. Automated cutting, bending, and assembly processes not only enhance efficiency but also ensure consistency and precision in component manufacturing.

Enhanced Structural Integrity: Modern vehicles demand higher safety standards. Sheet metal fabrication techniques have adapted to produce components with improved structural integrity, essential for enhancing vehicle safety and durability.

Rapid Prototyping: The ability to rapidly prototype sheet metal parts accelerates the development of new vehicle models. This agility is crucial in an industry where speed-to-market can be a competitive advantage.

Cost-Effective Production: With the advancement of fabrication technologies, producing complex parts has become more cost-effective. This allows automotive manufacturers to offer more features at competitive prices, driving consumer demand.

Customization at Scale: As consumer preferences shift towards personalized vehicles, sheet metal fabrication must adapt to offer customization options at scale. This involves flexible manufacturing processes that can handle varied designs without significant cost increases.

Collaboration with Aerospace Techniques: Borrowing techniques from the aerospace industry, such as advanced alloy processing and precision engineering, has allowed automotive sheet metal fabrication to reach new levels of quality and efficiency.

In the automotive realm, sheet metal fabrication is more than a manufacturing process; it’s a driver of technological progress, shaping the future of mobility with every bend and cut.

Navigating the Intricacies of Thin Sheet Metal Fabrication

Thin sheet metal fabrication, often seen as a delicate balancing act in the manufacturing world, entails a set of specific challenges and demands precision and expertise.

Precision Handling: Thin metals, due to their flexibility and delicacy, require highly precise handling to avoid deformations. Precision in cutting and bending is paramount, often demanding tighter tolerances compared to thicker materials.

Cutting Techniques: The choice of cutting technique is critical. Laser cutting, for instance, offers the precision necessary for thin metals but requires careful calibration to prevent material warping due to heat exposure.

Material Selection: Not all metals exhibit the same characteristics when thinned. Materials like aluminum and stainless steel, each with distinct properties, must be chosen based on their ability to retain structural integrity at reduced thicknesses.

Welding Considerations: Welding thin metals demands expertise, as the risk of burn-through and warping is significantly higher. Techniques like TIG welding are often preferred for their control and precision.

Finishing Processes: Post-fabrication finishing must be undertaken with care to maintain the integrity of thin metals. Techniques like powder coating or anodizing need to be adjusted to ensure even application without adding undue stress to the material.

Controlled Deformation Management: One of the key challenges is managing deformation. Thin metals are prone to warping or bending undesirably during processes like cutting or bending. Adopting techniques that minimize stress and distribute force evenly is crucial.

Surface Integrity Maintenance: Maintaining the surface integrity of thin metals is paramount. Techniques that prevent scratching or marring are essential, especially when the aesthetic aspect is a priority.

Dimensional Accuracy: Achieving and maintaining dimensional accuracy is more challenging with thin metals due to their flexibility. Utilizing advanced measuring tools and techniques is necessary to ensure precision.

Custom Tooling Requirements: Often, standard tooling is not suitable for thin sheet metal fabrication. Custom or specialized tools may be required to handle these materials without causing damage.

Rapid Prototype Development: Thin sheet metals are commonly used in industries requiring quick prototyping. Adapting the fabrication process for rapid turnaround without compromising quality is a significant aspect of working with thin metals.

Temperature Regulation: Processes like welding require careful temperature control to prevent warping or burn-through. This often involves using specialized equipment or techniques.

Material Grain Considerations: The direction of the grain in thin sheet metals can significantly impact the final product, especially in bending operations. Awareness and careful planning considering the grain direction is essential.

Understanding these challenges is crucial for anyone involved in thin sheet metal fabrication. It’s a delicate balance of precision, material knowledge, and technique, vital for producing quality components in this specialized area.

Custom Enclosures Fabrication: Innovating for Efficiency and Reliability

Custom metal enclosures, a critical component in various industries, necessitate a sophisticated approach to fabrication. This article delves into the diverse aspects that define their creation, emphasizing efficiency, reliability, and innovation in the process.

Efficient Production Process: Modern sheet metal fabrication for custom enclosures hinges on efficient production processes. Utilizing automated systems and lean manufacturing techniques, fabricators can reduce waste and accelerate turnaround times without compromising on quality.

Enhanced Durability: A key focus is on enhancing the durability of the enclosures.

This involves using not only robust materials but also integrating design elements that improve resistance to environmental stressors such as moisture, dust, and extreme temperatures.

Adaptive Material Use: The choice of materials in custom enclosure fabrication is strategic, aiming for the optimal blend of strength, weight, and cost-effectiveness. Advanced alloys and composites are increasingly being used for their superior properties, including corrosion resistance and lightweight characteristics.

Precision Engineering: With advanced tools and equipment, precision in cutting, bending, and joining is achieved. This precision engineering ensures that the enclosures meet the exact specifications for protection and compatibility with other components.

Thermal Management Considerations: Particularly for electronic enclosures, effective thermal management is essential. Designs often incorporate features for heat dissipation, such as vents or thermal insulation, to safeguard sensitive components.

Customization for Specific Applications: The flexibility to tailor enclosures to specific industry needs – from small handheld device cases to large industrial cabinets – is a hallmark of modern sheet metal fabrication. This customization extends to aspects like size, shape, and the integration of unique features like cable management systems or security locks.

Compliance with Standards: Fabricating enclosures for various industries often requires adherence to strict standards and certifications. This compliance ensures that the enclosures can reliably protect and house equipment in regulated environments.

Integration of Advanced Coatings: The application of specialized coatings to enhance the enclosures’ properties is gaining traction. These coatings can provide additional protection against environmental factors, electromagnetic interference, or enhance thermal conductivity, extending the lifespan and functionality of the enclosures.

Collaborative Design Process: The shift towards a more collaborative design approach involves working closely with clients and end-users. This collaboration ensures that the final product not only meets technical specifications but also aligns with the users’ practical needs and preferences.

Modular Design Concepts: Modular designs in enclosure fabrication offer flexibility and scalability. This approach allows for easy customization and adaptability to various applications, ranging from modular data centers to customizable medical device housings.

Innovative Joining Techniques: Beyond traditional welding and riveting, there’s an increased use of innovative joining techniques like adhesive bonding or magnetic assembly. These methods offer a cleaner, more aesthetically pleasing finish and can be more effective for certain materials or design requirements.

End-of-Life Considerations: There’s a growing emphasis on designing enclosures with end-of-life considerations in mind. This involves creating products that are easy to disassemble and recycle, minimizing waste and supporting circular economy principles.

Emphasis on User Safety: Safety is a paramount concern, particularly in industries like energy and healthcare. This leads to designs that prioritize user safety, incorporating features like fail-safe locks, insulated panels, and emergency access solutions.

In essence, the fabrication of custom metal enclosures is a blend of advanced technology, skilled craftsmanship, and an unwavering commitment to meeting the diverse and evolving needs of different industries. It’s a field where innovation and precision coalesce to create solutions that are as reliable as they are bespoke.

Sheet Metal Prototyping Versus Mass Production: Diverse Perspectives

Sheet metal fabrication, an industry rich in techniques and innovations, presents two distinct pathways: Prototyping and Mass Production. Each serves unique purposes and offers different advantages, depending on the project requirements.

Prototyping:

- Innovation and Flexibility: Prototyping is the playground for innovation, where designers and engineers test and refine their ideas. It allows for experimenting with unconventional designs or materials without the commitment of large-scale production.

- Speed and Adaptability: Prototypes are developed quickly to test concepts, making it easier to adapt and make changes based on feedback or testing results. This agility is crucial in industries where time-to-market is critical.

- Cost Implications: While per-unit costs may be higher due to lower volumes and lack of economies of scale, prototyping saves costs in the long term by identifying design flaws early, avoiding expensive revisions post-production.

Mass Production:

- Economies of Scale: Mass production significantly reduces the cost per unit, making it a cost-effective solution for large orders. This efficiency is achieved through streamlined processes and automation.

- Consistency and Quality Control: Repeatability is a hallmark of mass production. With standardized processes, there is less variability, leading to consistent quality across thousands of parts.

- Resource Allocation: Mass production requires more initial investment in tooling and setup but maximizes resource utilization over large production runs, offering a higher return on investment.

Strategic Decision-Making:

- Market Demand: Prototyping is favored in niche markets or for bespoke solutions, while mass production caters to widespread market demands.

- Resource Availability: The choice between the two methods also depends on the availability of resources, including machinery, materials, and skilled labor.

- Long-Term Objectives: Strategic decisions should consider long-term business objectives. While prototyping is crucial for R&D and innovation, mass production is key for market expansion and sustaining large customer bases.

In conclusion, the dichotomy between sheet metal prototyping and mass production is not just a choice of manufacturing techniques but a strategic decision impacting the entire product lifecycle. Balancing these two approaches according to project needs, market trends, and long-term goals is vital for success in the dynamic world of sheet metal fabrication.

Selecting the Right Sheet Metal Fabrication Supplier in China

Finding a suitable sheet metal fabrication supplier in China demands a careful assessment of several key factors. The goal is to partner with a provider that ensures quality, reliability, and value for your specific project needs.

1. Assess Technical Capabilities and Expertise:

- Seek suppliers with advanced machinery and technologies capable of handling diverse fabrication tasks.

- Opt for suppliers with a proven track record in your specific industry or for similar projects.

2. Quality Assurance and Standards:

- Investigate their quality control measures and adherence to international quality standards.

- Look for suppliers with certifications such as ISO 9001, indicating a commitment to consistent quality.

3. Communication and Customer Service:

- Effective communication is crucial for understanding project requirements and ongoing coordination.

- Evaluate their responsiveness and willingness to provide custom solutions.

4. Production Capacity and Timeliness:

- Consider their ability to meet your deadlines, especially for large-scale or urgent projects.

- Assess their flexibility in handling order fluctuations and last-minute changes.

5. Cost-Effectiveness Without Compromising Quality:

- Analyze the balance between cost and quality; the cheapest option is not always the best.

- Consider long-term value over short-term savings.

6. Experience in International Shipping and Logistics:

- Ensure they have experience in international shipping and can handle logistics efficiently.

Why Choose Premium as Your Sheet Metal Fabrication Supplier in China?

Premium Stands Out:

1. Advanced Technological Infrastructure:

- Premium employs cutting-edge machinery like precision laser cutters and automated bending machines, ensuring high-accuracy and repeatability in fabrication.

2. Comprehensive Material Expertise:

- Their expertise extends beyond standard materials to include specialized alloys, providing solutions for even the most challenging projects.

3. Proven Track Record in Complex Projects:

- Premium has a portfolio of successfully completed projects involving intricate designs and strict tolerances, showcasing their capability to handle complex requirements.

4. In-House Design and Engineering Support:

- They offer design and engineering assistance, helping clients refine their designs for manufacturability and cost-effectiveness.

5. Stringent Quality Control Systems:

- With a rigorous quality management system, each project undergoes thorough inspections and quality checks at every stage of production.

6. Flexible Production Capabilities:

- Premium is equipped to handle both small-scale prototyping and high-volume production runs, adapting seamlessly to varying client demands.

7. Short Lead Times and Reliable Delivery:

- They prioritize efficient production processes and have a reliable supply chain, ensuring shorter lead times and on-time delivery.

8. Competitive Pricing Without Quality Compromise:

- Premium provides cost-effective solutions by optimizing production processes and material utilization, offering competitive pricing while maintaining high quality.

9. Experienced in International Collaboration:

- With extensive experience in serving global clients, Premium understands the nuances of international standards and logistics, ensuring smooth transactions for overseas clients.

10. Custom Finishing Options:

- They offer a range of finishing services, including powder coating, anodizing, and plating, to enhance the aesthetic and functional properties of the fabricated parts.

11. Environmental Responsibility:

- Premium adheres to environmentally responsible practices, including efficient material usage and waste management, aligning with sustainability goals.

12. After-Sales Support and Services:

- They provide reliable after-sales support, addressing any concerns post-delivery and offering services like maintenance and part replacements.

Choosing the right sheet metal fabrication supplier in China is pivotal to the success of your project. Premium embodies the ideal blend of technological prowess, quality assurance, industry expertise, customer-centric service, timely delivery, and cost-effectiveness, making it a superior choice for your sheet metal fabrication needs.

Cost-Effective Strategies in Sheet Metal Fabrication: Balancing Budget and Quality

In sheet metal fabrication, balancing cost-effectiveness with quality is paramount. This article provides insights on strategies to manage costs while maintaining the quality of metal fabrication projects.

Smart Material Selection: Choosing the right material is crucial. Opt for cost-effective yet durable materials, and consider the trade-offs between cost and performance. For example, mild steel is less expensive than stainless steel but may require additional finishing.

Efficient Design Optimization: Utilize CAD tools for designing. Simplify designs to reduce unnecessary complexity, which can escalate costs. Focus on designs that minimize waste and are easy to fabricate.

Leveraging Technology: Invest in advanced fabrication technologies like laser cutting and CNC

machining. These technologies, while initially costly, offer long-term savings through precision and reduced waste.

Modular Design Approach: Implement a modular design system where possible. This approach allows for the reuse of standard components across different projects, reducing the need for custom fabrication and lowering costs over time.

Optimizing Sheet Utilization: Maximize material utilization by optimizing sheet layouts. Advanced software can plan layouts to minimize waste, effectively utilizing every inch of the sheet metal and reducing material costs.

Streamlining the Production Process: Implement lean manufacturing principles. This includes optimizing workflow, reducing material handling time, and minimizing production steps without compromising the fabrication quality.

Bulk Purchasing of Materials: For large-scale projects, bulk purchasing of raw materials can significantly reduce costs. Negotiate with suppliers for the best prices without sacrificing material quality.

Regular Maintenance of Equipment: Ensure regular maintenance of fabrication equipment. Well-maintained machinery operates more efficiently and reduces the likelihood of costly downtime or repairs.

Collaborative Supplier Relationships: Build strong relationships with suppliers. Collaborative partnerships can lead to better material prices, improved quality, and even joint efforts in R&D for more cost-effective fabrication solutions.

Regular Cost Analysis: Continuously analyze and monitor fabrication costs. Understanding where money is spent can highlight areas for potential savings and efficiency improvements.

By combining these strategies with a keen understanding of your specific fabrication needs, you can effectively manage costs without compromising on the quality of your sheet metal projects. It’s about making smart choices at every step of the fabrication process.

Contact Us

Get Started With Premium Rapid & Mold Now!

We always want to make sure that our customers are getting the best deal, so let us know what you’re interested in and we’ll get back with a quote!