Are you struggling to meet tight deadlines to get your product to market? Do you need high-quality, accurate prototype parts fast? We know you have to be first to market. With over 20 years of experience, our quick turn prototype sheet metal fabrication services are designed to meet your needs quickly and effectively.

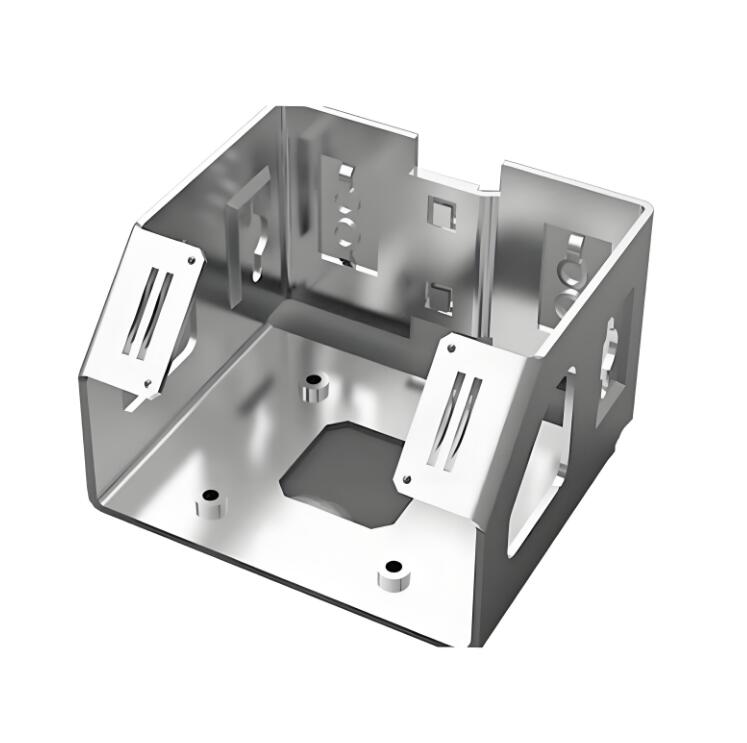

Quick turn prototype sheet metal fabrication services provide fast, high-quality production of custom parts to keep your projects on track. Using advanced techniques like laser cutting and CNC bending, we deliver accurate, reliable prototypes in just days to support your journey from design to production.

Imagine taking your hand sketches, detailed prints, or CAD models and turning them into physical, precision-fabricated sheet metal parts in just a few days. Our team is responsive to deadlines. From quoting to programming to forming and finishing, we treat every job as a rush job. With 25,000+ sq. ft. of manufacturing space and state-of-the-art equipment, we make sure your prototypes meet the highest quality standards.

When to Use Prototype Sheet Metal Fabrication?

New Product Development

Prototype fabrication is perfect for new product development. It allows designers and engineers to test and refine their ideas to make sure the final product meets all requirements.

Design Validation

Before you commit to large-scale production, you can use prototypes to validate the design’s functionality and performance. This step is critical for identifying potential issues and making needed changes.

Small Batch Production

If you only need a few units for your project, prototype fabrication is a cost-effective solution. You don’t have to worry about expensive tooling and setup costs associated with mass production.

Custom Parts and Components

When you need custom parts with unique specifications, prototype fabrication gives you the flexibility to make exactly what you need for a perfect fit in your application.

What Are the Key Processes in Prototype Sheet Metal Fabrication?

Laser Cutting

Laser cutting is a critical process in prototype sheet metal fabrication. It provides high precision and accuracy, making it perfect for intricate designs and parts. Our advanced laser cutters work with a variety of materials and thicknesses to provide clean edges with minimal waste.

Bending and Forming

Shaping and angling metal parts is a must. Using brake presses and die inserts, we can bend metal sheets into complex shapes with precise accuracy. This process is crucial to ensure the parts fit perfectly in your final product.

Welding and Assembly

Welding is another crucial step. Through processes like MIG, TIG, and spot welding, we can securely weld parts together, providing strength and durability. Our assembly services also include hardware insertion and finishing touches to meet your exact needs.

What Materials Are Ideal for Prototyping?

Aluminum

Aluminum is a top choice because it’s lightweight and non-corrosive. We work with alloys like 5052, 6061, and 7075 for a variety of applications, from aerospace components to consumer electronics.

Stainless Steel

Stainless steel is known for its strength and durability. We work with grades like 304 and 316L, which are perfect for medical devices and industrial equipment.

Mild Steel

Mild steel, specifically grade 1018, is affordable and versatile. It’s great for general-purpose applications where you need to stay on budget but don’t want to skimp on quality.

Specialized Materials

When you need specialty materials, we also work with copper and brass. Copper is a great electrical conductor, making it perfect for electronic applications, while brass is valued for its beauty and resistance to corrosion.

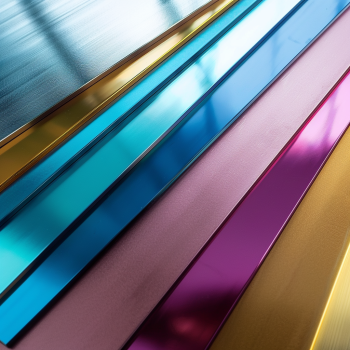

What Are the Surface Finishing Options?

Powder Coating

Powder coating gives you a durable, attractive finish that can resist impacts and corrosive environments. It’s great for outdoor applications or parts that need a tough, long-lasting surface.

Anodizing

Anodizing increases the corrosion resistance of aluminum parts, making them tougher in harsh environments. It also allows for various color finishes, improving both the protection and appearance of the parts.

Bead Blasting

Bead blasting provides a consistent matte finish, which is great for prepping surfaces for additional coatings or adding texture to the part. This process ensures a clean, uniform appearance.

Electroplating

Electroplating is a process where you coat the surface of the metal with a thin layer of another metal, like nickel, chrome, or gold. This can enhance corrosion resistance, electrical conductivity, and appearance.

Passivation

Passivation is a chemical treatment that removes free iron from the surface of stainless steel to improve its corrosion resistance. This is critical for medical devices and food processing equipment.

Black Oxide

Black oxide is a conversion coating applied to ferrous materials to improve corrosion resistance and reduce light reflection. It gives a nice black appearance that is great for aesthetics.

Silk Screening

Silk screening is when you use ink or paint through a mesh stencil to create detailed graphics or text on the metal surface. This is great for branding and labeling.

Brushing

Brushing is a process that creates a unidirectional satin finish on the surface of the metal. This is often used for decorative purposes to give a sleek, modern appearance.

Polishing

Polishing is a process that enhances the surface finish of the metal to make it look like a mirror. It’s great for applications where you need high reflectivity and appearance.

Chemical Conversion Coating

Chemical conversion coatings, like chromate conversion, provide a protective layer that improves corrosion resistance and paint adhesion. This is often used on aluminum.

E-Coating

E-coating, or electrophoretic deposition, is a process where you apply an electrically charged paint to the metal surface. This creates a uniform coating that provides excellent corrosion resistance, especially in hard-to-reach areas.

Why Choose Our Prototype Sheet Metal Fabrication Services?

Rapid Development

Our quick turn services mean you get your prototype parts in days, not weeks. This fast turnaround helps you get your product to market faster, so you can beat your competition.

Cost-Effective Solutions

We use materials and processes efficiently, making our services perfect for small batch runs. This approach helps you save money while maintaining high quality.

Design Flexibility

With prototypes, you can easily make changes to your design. Our team can make design adjustments quickly to make sure the final product meets all your requirements.

High-Quality Standards

We have a team of experienced, skilled fabricators that ensure you get the quality you need in your prototype parts. We also have the latest equipment to make sure your parts are precise and accurate.

What Are Our Expertise and Capabilities?

Experience and Facility

With over 20 years in business and 25,000+ sq. ft. of precision sheet metal manufacturing, we have the experience and capacity to handle any job.

State-of-the-Art Equipment

Our shop is equipped with triple axis CNC press brakes, punch presses with auto-loading turrets, and dedicated laser cutting, punching, and forming services. This advanced machinery allows us to produce high-quality parts quickly.

Full Scale Services

From quoting to programming, punching, forming, hardware insertion, welding, finishing, and inspection, we handle every aspect of the manufacturing process. Our in-house powder coating operation and relationships with local suppliers for other coatings ensure we meet all your finishing needs.

Expedited Services

When you need parts fast, we offer expedited services. Our team is committed to delivering prototypes on time, meeting tight deadlines without sacrificing quality.

What Are Our Rapid Sheet Metal Prototyping Service Capabilities?

Quick Turnaround

We deliver prototype parts in days, supporting hand sketches, detailed prints, or CAD models. Our goal is to have your prototypes when you need them.

Dedicated Equipment for Prototyping and Production

We have the capacity to meet prototyping and production needs. Our equipment is dedicated to running larger volume jobs, making sure we can scale up as needed.

How to Design for Manufacturing?

Best Practices for Design

Designing with the manufacturing process in mind can help you save money and speed up production. Best practices include considering hems & offsets, notches & tabs, corners & welding, and maintaining uniform thickness.

Cost Reduction

By bringing us in early during the design process, we can give you recommendations to optimize for manufacturing. This improves your product design and saves you money.

Design for Manufacturability (DFM)

When you bring us in early, we can help you design parts that are easier to make. This ensures faster turnaround and lower costs

Frequently Asked Questions (FAQs)

What is a Prototype Sheet Metal Fabricator?

A prototype sheet metal fabricator specializes in producing small quantities of custom-designed parts. We use advanced techniques for testing, experimentation, and evaluation to make sure your prototypes meet the highest standards.

Working with us gives you access to advanced

manufacturing techniques and equipment for quick iteration on designs and prototypes. This process ensures your parts are made efficiently and to your exact specs.

What Materials Are Used for Sheet Metal Fabrication?

We use a variety of materials, including steel, stainless steel, aluminum (5052, 6061, 7075), copper, brass, and more. The material choice depends on the intended use, structural requirements, and desired look.

What is the Typical Lead Time for Sheet Metal Fabrication Prototypes?

Lead times can vary based on the complexity of the design, material availability, and our workload. Typically, we can have parts made in days or weeks, depending on the project’s scope.

How Can I Find a Reliable Prototype Sheet Metal Fabricator?

To find a reliable fabricator, do your research on potential companies. Look for experience in your particular type of fabrication, ask for references or examples of past work, and consider factors like pricing, lead time, and customer service.

Conclusion

Quick turn prototype sheet metal fabrication is critical to staying ahead in product development. Our services provide fast, high-quality production of custom parts to meet your tight deadlines and exact specs. Trust us to support you from design to production, delivering prototypes to help you succeed.