Plastic Injection Molding Manufacturer

Experience Precision Injection Molding with Premium: Your Partner in Delivering Durable, Efficient, Quality Solutions

The Injection Molding Services Premium offers you

Premium is a leading provider of injection molding services, offering custom, high-quality solutions for diverse applications. Boasting advanced manufacturing facilities and extensive experience, we leverage our deep industry expertise to ensure clients receive products precisely tailored to their specifications and needs.

Rapid Molding

Accelerate your project’s pace with Premium’s Rapid Molding, offering swift production of prototypes and short runs. Our precise, quality-focused approach ensures your urgent needs are met promptly, keeping your project timeline on track without compromising on the final product’s quality.

Insert Molding

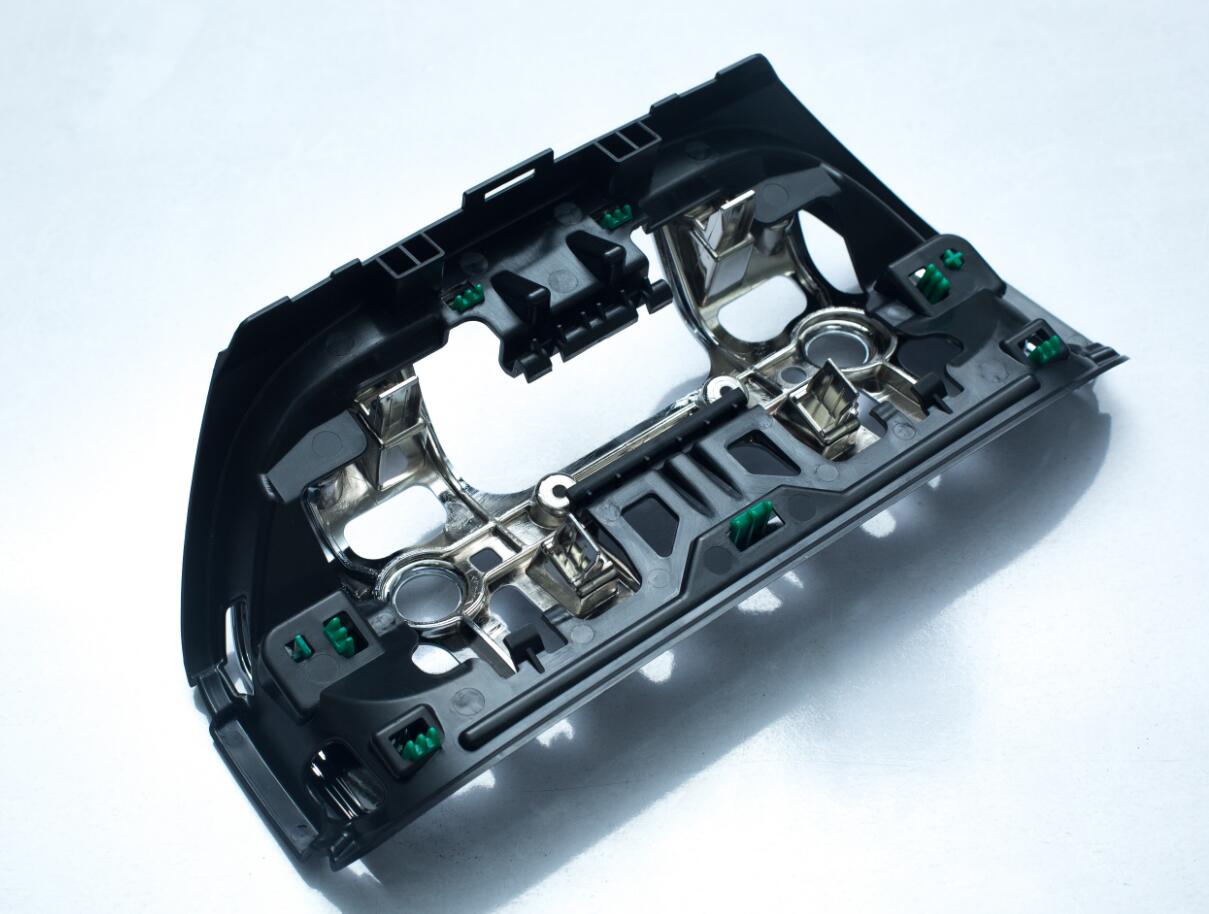

Enhance your parts’ strength and functionality with Premium’s Insert Molding. We skillfully combine metal or different plastics within a single component, providing robust, intricate designs ideal for complex applications. This technique is perfect for parts demanding durability and multifunctionality.

2K Molding

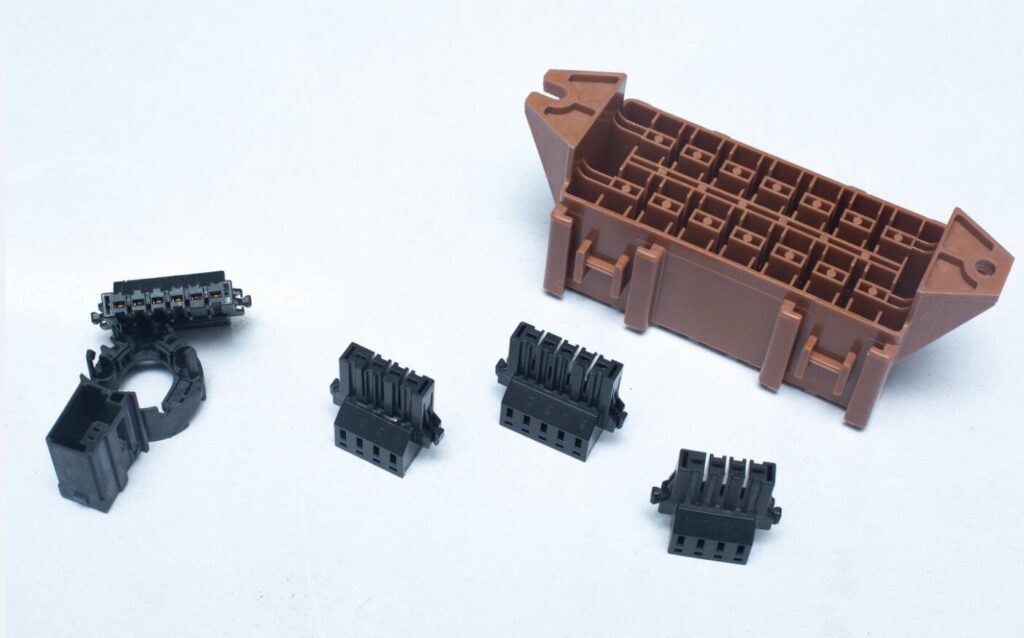

Discover the versatility of Premium’s 2K Molding, where two different materials merge in one mold cycle. This method is excellent for creating parts with varied textures, colors, or functionalities, efficiently producing innovative components that meet diverse design requirements.

Family Molding

Maximize efficiency with Premium’s Family Molding, allowing simultaneous production of multiple parts. This cost-effective approach reduces production time and expense while ensuring consistent quality across different components, ideal for product families requiring varied yet uniform parts.

Overmolding

Upgrade your products with Premium’s Overmolding, enhancing them with additional material layers. This method improves ergonomics, durability, and aesthetics, providing a superior user experience. It’s ideal for products requiring a soft touch, additional grip, or reinforced structure

Liquid Silicone Rubber Injection Molding

Opt for Premium’s Liquid Silicone Rubber Injection Molding for high-precision, flexible parts. Our expertise caters to demanding sectors like medical, automotive, and consumer products, delivering components that are durable, heat-resistant, and tailored to your exact specifications

Your wide range of injection molding solutions supplier in China

Grasping the distinct needs of your project is key at Premium. As a renowned provider of injection molding services, we are dedicated to ensuring precision and tailor-made solutions at every phase of your project’s journey.

1.Design Adaptability and Complexity: Effortlessly manage complex designs with Premium, ensuring feasible, precise execution of intricate geometries and configurations.

2.Material Selection Diversity: Choose from Premium’s extensive range of advanced polymers and composites for optimal material properties and performance.

3.Advanced Molding Techniques: Explore Premium’s diverse molding options like Rapid, Insert, 2K, and Overmolding, each providing unique, specialized advantages.

4.Precision Tolerance and Accuracy: Rely on Premium for precision injection molding with exact tolerances, ensuring dimensional and functional accuracy of components.

5.Finish and Texture Customization: Customize finishes and textures with Premium, from high-gloss to textured options, enhancing your parts’ appearance and functionality.

Easily Tailor Your Plastic Injection Molding Components

Experience seamless customization in injection molding with Premium. We’ve honed our process to ensure your custom molding projects are delivered without the usual complexities. Our efficient four-step method, supported by a team of professionals, guides you smoothly from project conception to precise production.

Understanding Project Requirements Detail your project’s specifics – materials, functionality, conditions – enabling us to tailor our approach for your unique injection molding needs.

-1024x683.jpg)

Design Optimization and DFM Define your design goals; our DFM principles streamline them for efficient production, reducing costs while enhancing quality.

Material Selection & Process Determination Select the optimal materials and processes for your project, balancing performance and cost, guided by our expert advice.

Precision Engineering and Production Send us your designs; our skilled engineers and state-of-the-art equipment ensure each part meets your exact requirements for quality and dimensions.

Why Choose Injection Molding Service from Premium Mold?

As a distinguished provider in injection molding, Premium Mold is dedicated to delivering top-quality, innovative solutions. Our extensive experience ensures exceptional precision and performance in every custom-molded part, making us a reliable choice in the industry.

1.Innovative Customization: “Premium tailors injection molding solutions to your specifications, ensuring products meet your unique needs with unmatched precision and innovation.”

2.Advanced Manufacturing Techniques: “Stay ahead with Premium’s cutting-edge molding technologies, designed to meet both current and evolving industry demands efficiently.”

3.Production Excellence: “With our state-of-the-art facilities and dedication to continuous improvement, Premium sets new benchmarks in precision, quality, and reliability.”

4.Cost-Effective Solutions: “Choose Premium for competitively priced, high-quality injection molding services, offering exceptional value to businesses of all sizes.”

-1024x683.jpg)

FAQs About Plastic Injection Molding Services

We’ve compiled the most frequently asked questions about our injection molding services for your convenience. However, should you have any additional questions, please don’t hesitate to contact us.

2K molding simultaneously injects two materials in one cycle for cohesive parts, while overmolding adds a secondary material layer to an existing part.

Rapid molds typically have a shorter lifespan, designed for quick prototyping and small runs, usually lasting for thousands of shots

A wide range, including ABS, polycarbonate, polyethylene, and specialized composites, depending on the desired properties and application.

Overmolding enhances product functionality and aesthetics, adding soft-touch surfaces, extra layers for durability, or multi-material components.

High-speed molding is for large-volume production with quick cycle times, while rapid molding focuses on speed in prototyping and small runs.

Consider part complexity, material, production volume, and final application. Premium can assist in selecting the most suitable method based on these factors

Rapid molds typically have a shorter lifespan, designed for quick prototyping and small runs, usually lasting for thousands of shots.

Premium employs rigorous quality checks, including dimensional accuracy using CMMs, and adheres to strict material and production standards.

Yes, our team offers Design for Manufacturing (DFM) services, optimizing your designs for efficient and cost-effective production.

How does Premium manage complex injection molding projects?

We optimize designs for manufacturability, select materials wisely, and employ efficient production techniques to reduce waste and save costs."

Premium Mold stands out for its advanced technology, customized solutions, expert team, and commitment to quality and client satisfaction.

We offer comprehensive after-sales support, including troubleshooting, quality assurance follow-ups, and assistance with any additional modifications or future projects. coast

Yes, we tailor solutions based on your project requirements - from material selection and design optimization to choosing the appropriate molding technique.

Premium: Your One-Stop Solution for Injection Molding Excellence

At Premium, we blend state-of-the-art injection molding, precision mold making, expert surface finishing, stringent quality assurance, secure packaging, and globally recognized certifications to deliver unparalleled manufacturing solutions, tailored to meet and exceed your diverse industry needs with efficiency, innovation, and quality.

Discover state-of-the-art injection molding at Premium, featuring both vertical and horizontal machines. Our fleet includes Haitian and Yangxin two-color molders, and renowned Japanese brands like Kawaguchi and Nissei, ranging from 25 to 800 tons.

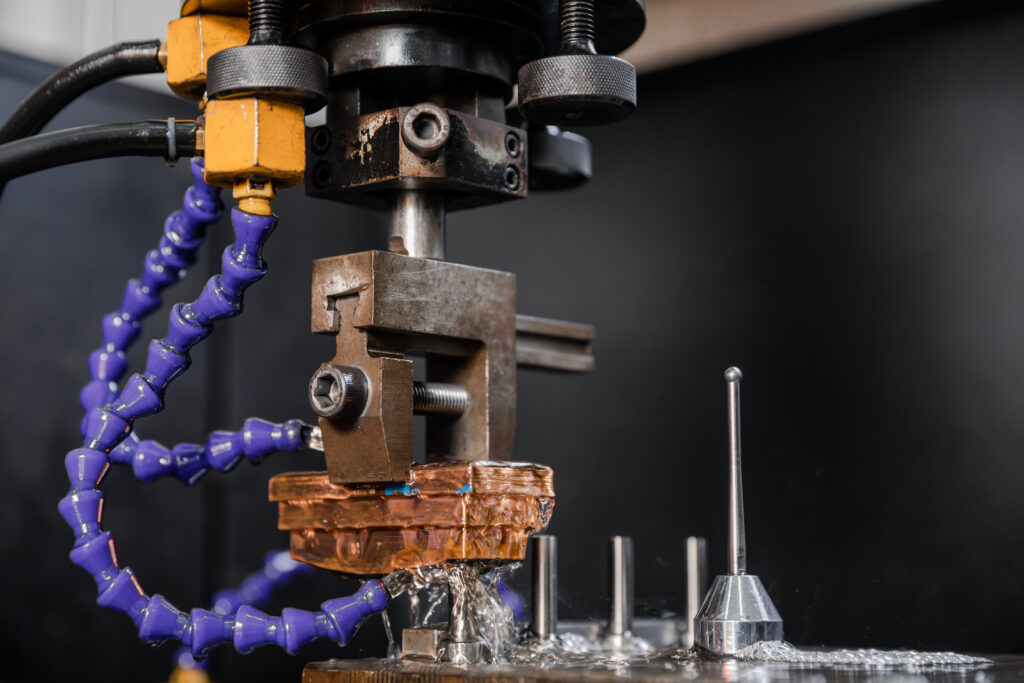

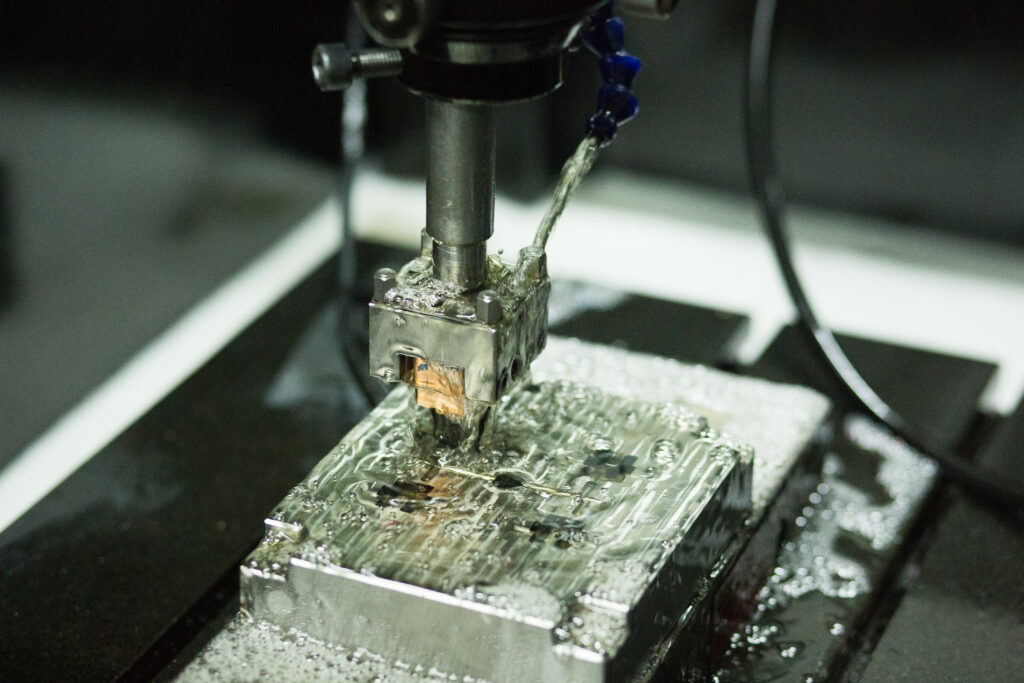

At Premium, precision mold making is achieved with top-tier CNC machines from Mikron, YASDA, FANUC, and advanced equipment like Fanuc slow-speed wire cutters and Makino spark machines, ensuring up to 0.02μ grinding and 5μ CNC precision.

Experience the pinnacle of surface finishing for injection molded products at Premium. Our expertise covers specialized finishes such as texturing, high-gloss polishing, and pad printing to enhance the appearance and feel of your products. We use techniques like hot stamping and silk-screening for detailed branding and labeling, ensuring each part not only performs excellently but also looks exceptional.

At Premium, our production process embraces stringent quality inspections, including in-process checks, systematic sampling, and final evaluations in line with industry norms. Utilizing tools like calipers, 2D measurement systems, CMMs, and hardness testers, we ensure the highest standards. Explore our meticulous quality assurance through images showcasing our sophisticated testing equipment and detailed inspection procedures.

Your injection molded parts are safeguarded with utmost care. We employ durable, lightweight packaging materials including specialized cartons and protective pallets, tailored to the size and sensitivity of the products. This ensures secure, cost-effective shipping and handling, maintaining the integrity of your parts from our factory to your doorstep.

Trust Premium’s commitment to excellence, certified by ISO9001, ISO14001, IATF16949, and ISO13485. Our certifications reflect our dedication to quality, environmental management, automotive standards, and medical device manufacturing excellence.

Navigating Your plastic injection molding services Purchase: The Comprehensive Guide

Embark on a journey through Premium’s Plastic Injection Molding Services. Whether for intricate designs or mass production, our guide illuminates every facet of our top-quality offerings. Let us streamline and enrich your sourcing experience, ensuring efficiency and insight at every step of your plastic injection molding project.

Table of Contents

What is Plastic Injection Molding Service ?

Plastic injection molding is a manufacturing process widely used for producing parts in large quantities. It involves melting thermoplastic pellets, which are then injected at high pressure into a mold cavity. This cavity is designed to match the desired shape of the part. Once the molten plastic is injected, it cools and solidifies, forming a solid part.

This technique is renowned for its precision and ability to produce complex shapes that would be difficult or cost-prohibitive with other manufacturing processes. Its versatility allows for the use of a wide range of materials, enabling the production of parts with varying characteristics like rigidity, flexibility, and heat resistance.

-1024x683.jpg)

Key benefits of plastic injection molding include its high efficiency and ability to scale up production. Once the initial costs of designing and creating the mold are covered, the process becomes highly economical for mass production, offering a lower per-unit cost.

For businesses looking to produce high-quality, consistent parts at a competitive price, plastic injection molding presents an optimal solution. It’s particularly beneficial for industries where parts need to meet strict dimensional tolerances and where high repeatability is essential. Whether it’s automotive components, consumer electronics, or medical devices, plastic injection molding is a reliable and cost-effective choice for manufacturing complex parts.

On-Demand Injection Molding Services: Revolutionizing Manufacturing Efficiency

In today’s fast-paced market, on-demand injection molding services are emerging as a game-changer, offering unparalleled flexibility and significantly reduced lead times. This innovative approach aligns seamlessly with the dynamic demands of modern industries, providing a tailored solution that is reshaping the landscape of plastic manufacturing.

At the heart of on-demand injection molding is the ability to swiftly respond to client needs, whether it’s for prototyping or full-scale production. This agility is crucial in sectors where time-to-market can be a critical competitive advantage. By leveraging the latest in automation and digital manufacturing technologies, these services enable the production of high-quality parts with speed and precision, catering to both small and large-scale requirements.

The precision in modern injection molding is remarkable, with tolerances as tight as ±0.02 mm, accommodating a wide array of materials from standard thermoplastics to advanced composites. This versatility ensures that regardless of the complexity or specificity of the part, the final product meets the exacting standards expected in industries such as medical, automotive, and consumer electronics.

Sustainability is another pivotal aspect, with many on-demand services utilizing eco-friendly materials and optimizing production processes to minimize waste. This approach not only aligns with environmental responsibilities but also resonates with the growing consumer demand for sustainable products.

In summary, on-demand injection molding services represent a significant stride in manufacturing efficiency. They offer a fast, flexible, and precise solution to meet the evolving needs of various industries, proving to be an invaluable asset in the toolkit of modern manufacturing.

Clarifying Plastic Injection Molding and CNC Machining

Plastic injection molding and CNC (Computer Numerical Control) machining are distinct manufacturing processes, each with unique methods and applications.

Injection molding is a process used to create plastic parts by injecting molten material into a mold. It’s highly efficient for mass production of parts with complex shapes and is known for its high precision and speed.

CNC machining, on the other hand, involves subtractive manufacturing. It uses computer-controlled machines to remove layers from a solid block of material to form a part.CNC machining is praised for its precision and is often used for metal parts or prototypes where intricate details and tight tolerances are required.

While both processes are controlled by computer systems and are crucial in the manufacturing industry, they serve different purposes. Injection molding is primarily used for high-volume production of plastic parts, whereas CNC machining is more suited for creating detailed prototypes or components, often from metal or hard plastics.

What Is The Advantage Of Plastic Injection Molding Service ?

Plastic injection molding is a pivotal technology in modern manufacturing, offering unparalleled benefits for a wide range of industries. Its foremost advantage is the ability to produce complex and intricate shapes with high precision, ensuring consistency in quality for each part. This is particularly vital for components requiring tight tolerances and detailed features.

Another significant benefit is its efficiency and speed. Once the mold is designed and created, the production process allows for rapid manufacturing of large quantities of parts, making it highly cost-effective, especially for mass production. This efficiency also translates into lower labor costs, as the process is largely automated.

Moreover, plastic injection molding supports the use of diverse materials, including various types of plastics with different properties, enabling customization of parts based on specific requirements like strength, flexibility, and heat resistance.

Additionally, the process minimizes waste, as excess material can often be recycled, making it a more sustainable manufacturing option.

For businesses looking to scale production while maintaining high-quality standards, plastic injection molding is an indispensable service, combining precision, efficiency, and versatility.

What is the Ideal Plastic Materials for Injection Molding ?

Selecting the right plastic material is crucial in plastic injection molding, as it determines the quality, functionality, and durability of the final product. Commonly used materials include:

1.ABS (Acrylonitrile Butadiene Styrene): Renowned for its toughness and impact resistance, ABS is ideal for a wide range of applications, from automotive parts to consumer goods.

2.Polycarbonate (PC): Known for its exceptional strength and transparency, PC is often used in applications requiring high impact resistance and clarity, like protective gear and eyewear.

3.Polypropylene (PP): With its excellent chemical resistance and elasticity, PP is a top choice for containers, automotive components, and living hinges.

4.Polyethylene (PE): Available in various densities, PE is valued for its versatility, lightweight nature, and moisture resistance, making it suitable for packaging and insulation.

5.Nylon (Polyamide): Distinguished by its high strength-to-weight ratio and thermal stability, Nylon is often used in mechanical and engineering applications.

Each material offers distinct properties, making them suitable for specific applications. The choice of material depends on the desired characteristics of the final product, such as flexibility, durability, and resistance to heat or chemicals. Understanding these materials and their applications is key to optimizing your product’s performance and longevity.

The Cost-Effectiveness of Plastic Injection Molding

-1024x562.jpg)

In the dynamic world of plastic injection molding, the pursuit of cost-effectiveness is a critical factor driving industry success. This process, known for its precision and scalability, offers a unique blend of quality, efficiency, and affordability, making it a favored choice across various sectors.

Central to the cost-effectiveness of injection molding is the minimization of material waste. The precision of modern injection molding machines ensures that the exact amount of plastic is used for each part, significantly reducing excess. This efficiency is crucial in an industry where raw material costs can significantly influence overall expenses.

The high repeatability of the injection molding process is another key factor. Once the initial investment in mold design and machine setup is made, the cost per unit becomes remarkably low, especially in high-volume production. This scalability makes injection molding an economically viable option for large orders, where the amortization of upfront costs over a large number of parts can lead to substantial cost savings.

Additionally, the versatility of injection molding in terms of material selection allows manufacturers to choose from a range of plastics to find the most cost-effective solution that meets the specific requirements of the product. From standard thermoplastics to advanced composites, the options are vast and varied, enabling customization without a hefty price tag.

Incorporating automation in injection molding processes also contributes to cost reduction. Automated systems for tasks like feeding, mold release, and quality inspection reduce labor costs and enhance production efficiency. Moreover, the consistent quality achieved through automation minimizes the rate of defective parts, further reducing waste and cost.

In conclusion, plastic injection molding stands out as a cost-effective manufacturing method. Its ability to produce high-quality parts at scale, with minimal waste and reduced labor costs, makes it an attractive option for businesses looking to optimize their production budgets without compromising on quality or efficiency.

What is The Differences Between Plastic Injection Molding and Casting ?

Plastic injection molding and casting are both methods for producing plastic parts, but they differ significantly in their processes and applications.

Injection molding involves melting plastic pellets and injecting the molten plastic into a mold under high pressure. This method is highly efficient for mass-producing parts with complex shapes and fine details. It offers high precision, consistency, and is suitable for a wide range of materials. However, it requires significant upfront investment in mold design and production.

On the other hand, plastic casting involves pouring liquid plastic into a mold without the use of high pressure. This method is simpler and less expensive in terms of equipment and mold costs, making it ideal for small-scale production or prototypes.

Casting is suitable for creating larger parts and those with simpler geometries. However, it generally lacks the precision and efficiency of injection molding and is limited in the types of materials that can be used.

In summary, while both processes are used to create plastic parts, injection molding is preferred for high-volume, high-precision production, whereas casting is more suitable for low-volume, less complex projects.

Choosing the Right Injection Molding Type for Your Project ?

Selecting the appropriate injection molding type for your project is crucial for achieving desired outcomes. Key factors to consider include:

Material Requirements: Assess the properties needed in your final product, such as strength, flexibility, and heat resistance. Different materials suit different applications, so choosing the right plastic is essential.

Part Complexity and Size: The complexity of the design dictates the type of molding machine and mold required. For intricate parts, advanced molding techniques with higher precision may be necessary.

Production Volume: High-volume projects benefit from traditional injection molding due to its efficiency and lower cost per unit at scale. For smaller runs, consider rapid injection molding or 3D printing as cost-effective alternatives.

4.Cost Considerations: Balance the upfront costs of mold design and production with the long-term benefits. Higher initial investments can lead to lower per-unit costs in mass production.

5.Lead Time: Determine your timeline. Some molding processes are faster than others, which can be critical in time-sensitive projects.

Understanding these factors helps in making an informed decision, aligning the molding process with the specific needs of your project for optimal results.

Is Injection Molded Plastic Strong ?

Injection molded plastics are renowned for their strength and durability, which can be attributed to the materials used and the precision of the molding process. The strength of a plastic part depends on the type of plastic material chosen. High-strength plastics like ABS, polycarbonate, and certain grades of polyamide are commonly used in applications that require robustness, such as automotive parts, safety gear, and electronic housings.

The injection molding process itself contributes to the strength of the product. The high pressure used in injecting molten plastic into the mold ensures dense, consistent material structure, eliminating voids and weak points. Additionally, the possibility of incorporating reinforcements like glass or carbon fibers further enhances the strength of the final product.

The design of the mold and the part also plays a crucial role. Proper design can maximize strength while minimizing material usage and weight. Features like ribs and gussets are often used to increase strength and rigidity in critical areas.

In conclusion, injection molded plastics can achieve impressive strength and durability, making them suitable for a wide range of applications, from everyday items to critical components in demanding environments. The key lies in selecting the appropriate material and optimizing the design for strength.

How Does Injection Molding Work?

Injection molding is a manufacturing process for producing parts by injecting molten material into a mold. It starts with feeding plastic pellets into a hopper. These pellets are then moved towards the mold by a screw mechanism, where they are heated until they melt.

Once the plastic is molten, it’s injected into a pre-designed mold under high pressure. This mold is a hollow cavity shaped like the desired part and is typically made from steel or aluminum for durability.The high pressure ensures that the plastic fills every part of the mold, capturing all the details and complexities of the design.

After the plastic is injected, it’s cooled rapidly. As it cools, it solidifies into the shape of the mold. The mold then opens, and the newly formed part is ejected. This process allows for high-precision and high-volume production of complex shapes with excellent surface finish. Its versatility makes it suitable for a wide range of applications, from small components to large parts.

How to Finding a Good Plastic Injection Molding Supplier in China

To find a reliable plastic injection molding supplier in China, consider several key factors:

1.Experience and Expertise: Look for suppliers with a strong track record in the industry. Experienced suppliers are more likely to understand the nuances of complex projects and can provide valuable insights.

2.Quality Assurance: Ensure the supplier has robust quality control processes. Check for certifications like ISO 9001, which indicate adherence to international quality standards.

3.Production Capabilities: Assess whether the supplier can handle the size and complexity of your project. This includes their machinery, technology, and capacity to meet your demand.

4.Communication and Service: Good communication is crucial for any successful partnership. Choose a supplier who is responsive and willing to collaborate closely with you throughout the project.

5.Client Testimonials and References: Seek feedback from previous customers to gauge the supplier’s reliability and the quality of their work.

6.Visit the Factory: If possible, visit the factory to get a firsthand look at their operations and capabilities.

7.Cost-Effectiveness: While cost is a factor, it should not be the only criterion. Balance cost with quality to ensure value for money.

Selecting the right supplier in China is a balance of these factors, ensuring that you partner with a company that can meet your quality standards, production needs, and timelines.

Industries Utilizing Plastic Injection Molding

Plastic injection molding is a versatile manufacturing process employed across various industries due to its efficiency, precision, and ability to produce high volumes of complex parts. Key industries include:

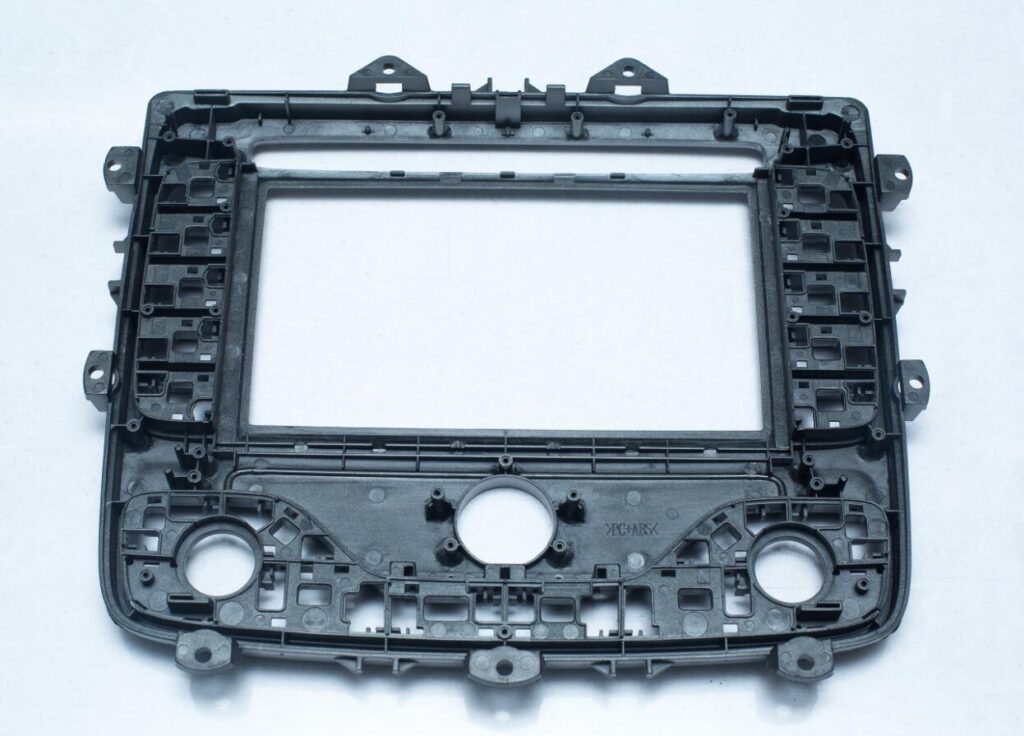

1.Automotive: Used for creating components such as dashboards, bumpers, and interior parts. The process’s precision and ability to use durable materials make it ideal for automotive applications.

2.Medical: Essential for producing sterile, high-precision components like surgical instruments, containers, and diagnostic equipment.

3.Consumer Electronics: Ideal for manufacturing parts of smartphones, computers, and other gadgets, due to its capability to produce detailed and consistent parts.

4.Packaging: Widely used for making containers, caps, and closures, offering durability and the ability to create air-tight seals.

5.Toys: Injection molding enables the production of complex toy designs, using safe and durable materials.

6.Construction: Produces a variety of components used in building and construction, such as fixtures and fittings.

7.Housewares: Common in creating kitchen gadgets, utensils, and appliances due to its flexibility in design and material choice.

Each industry benefits from injection molding’s ability to produce durable, high-quality parts efficiently and at scale, showcasing its broad applicability in modern manufacturing.

Essentials of Plastic Injection Molding Parts Design

Designing parts for plastic injection molding requires understanding the process’s capabilities and limitations to ensure functional, manufacturable, and cost-effective products. Key considerations include:

1.Wall Thickness: Consistent wall thickness ensures uniform cooling and reduces defects. Thickness should be minimized to save material and reduce cycle times while maintaining structural integrity.

2.Draft Angles: Incorporating draft angles (slight tapers) in the design of vertical walls is crucial for easy part ejection from the mold.

3.Ribs and Gussets: Use ribs and gussets to strengthen parts without excessively increasing wall thickness.

4.Minimize Undercuts: Undercuts complicate the molding and ejection process. Design to minimize them or use sliders and lifters if necessary.

5.Rounded Corners: Round off corners and edges to improve flow of molten plastic and reduce stress concentration, which can cause cracks and structural weaknesses.

6.Gate and Ejection Mark Placement: Strategically place gates and ejection marks where they won’t affect the part’s functionality or aesthetics.

7.Consider Shrinkage and Tolerances: Account for material shrinkage and design tolerances. Different plastics shrink at different rates, which must be considered in the design phase.

By adhering to these design principles, you can optimize part designs for the injection molding process, balancing functionality, aesthetics, and manufacturability.

Injection Molding for Automotive Applications: Precision and Durability in Vehicle Manufacturing

In the automotive industry, injection molding plays a pivotal role in manufacturing components with the utmost precision and durability. This process is instrumental in producing a wide range of automotive parts, from interior panels and dashboard elements to exterior body parts and under-the-hood components.

The precision in automotive injection molding is of paramount importance, as it ensures parts fit perfectly and function reliably. Modern injection molding techniques achieve tolerances as fine as ±0.005 inches, which is crucial in an industry where every millimeter counts. This accuracy is essential not just for the fit and function of individual parts but also for the overall safety and performance of the vehicle.

Durability is another critical aspect. Automotive components must withstand extreme conditions, including high temperatures, pressure, and chemical exposure. Injection molding allows the use of specialized materials like high-performance thermoplastics and reinforced composites that meet these demanding requirements.

Moreover, the efficiency of injection molding supports the high-volume production needs of the automotive sector. It enables manufacturers to produce large quantities of parts consistently and cost-effectively, a key factor in an industry that operates on tight margins and competitive pricing.

In summary, injection molding’s ability to deliver precision, durability, and efficiency makes it an indispensable technique in automotive manufacturing. It provides the tools needed to create safer, more reliable, and higher-quality vehicles, meeting the rigorous standards of the automotive industry.

Contact Us

Get Started With Premium Rapid & Mold Now!

We always want to make sure that our customers are getting the best deal, so let us know what you’re interested in and we’ll get back with a quote!