Finding the right sheet metal fabrication partner can be tough, especially when your project needs specialized solutions. The wrong choice can lead to delays, higher costs, and poor quality. To help you make the right decision, we’ve put together the key factors you need to consider to make sure your partnership is successful and your project gets done.

To choose the right sheet metal fabrication partner, evaluate their experience, technical capabilities, quality control processes, production capacity, design support, and customer service. Ensuring they meet these criteria will help you achieve your project goals efficiently and effectively.

Knowing how to find a quality sheet metal fabrication partner is critical to the success of any project. In this guide, we’ll take a closer look at the important things you should consider. By the end, you’ll be able to find and partner with a fabricator that meets your needs and delivers great results.

What Are Your Project Requirements?

Start by outlining what you need the sheet metal fabricator to do. That will help you narrow your search and find the fabricator that can do exactly what you need.

Identify Project Requirements

Decide what kind of sheet metal parts you need, what material you want them made from, how big they need to be, and how many you need. Having that information will help you talk to potential fabricators.

Specify Application

Understand what you’re going to do with the parts. That way, you can make sure the parts meet the specific standards for your industry, whether you’re in automotive, aerospace, medical, or any other industry.

How to Evaluate Technical Capabilities?

The technical capabilities of the sheet metal fabricator you choose are very important. You need to make sure the fabricator has the equipment and the know-how to do what you need.

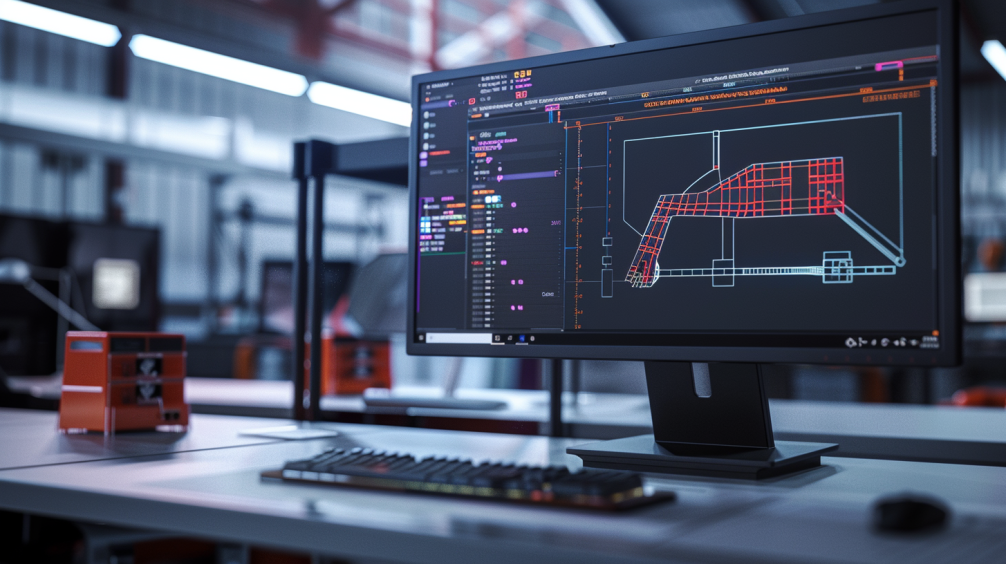

Equipment and Technology

Make sure the fabricator has the right equipment, like lasers, brakes, and punches. The best technology ensures better accuracy and faster production.

Material Expertise

Make sure the fabricator can work with the materials you need, like aluminum, steel, stainless steel, and copper. They need to be able to work with a variety of materials to meet your needs.

Why Is Quality Control Important?

Quality is critical when it comes to custom sheet metal fabrication. The fabricated metal parts you receive need to be strong and reliable, able to handle whatever you throw at them.

Do They Have Certifications?

Look for a fabricator that has certifications like ISO 9001, which means they have quality standards in place. You want to work with a fabricator that takes quality seriously.

How Do They Check Their Work?

Ask them how they inspect their work and what their defect rate is. The best fabricators have good inspection processes in place to make sure they produce consistent, high-quality parts.

What About Production Capacity?

Production capacity determines whether the fabricator can handle the volume of your project. Flexibility in handling different production scales is crucial.

Volume Flexibility

Confirm their ability to manage both small batch customizations and large-scale productions. This flexibility allows for adjustments as project demands change.

Lead Times

Ensure they can meet your delivery schedules without compromising quality. On-time delivery is vital for keeping your project on track.

How to Review Design Support?

A fabricator with strong design support can significantly enhance your project by optimizing designs for manufacturability and efficiency.

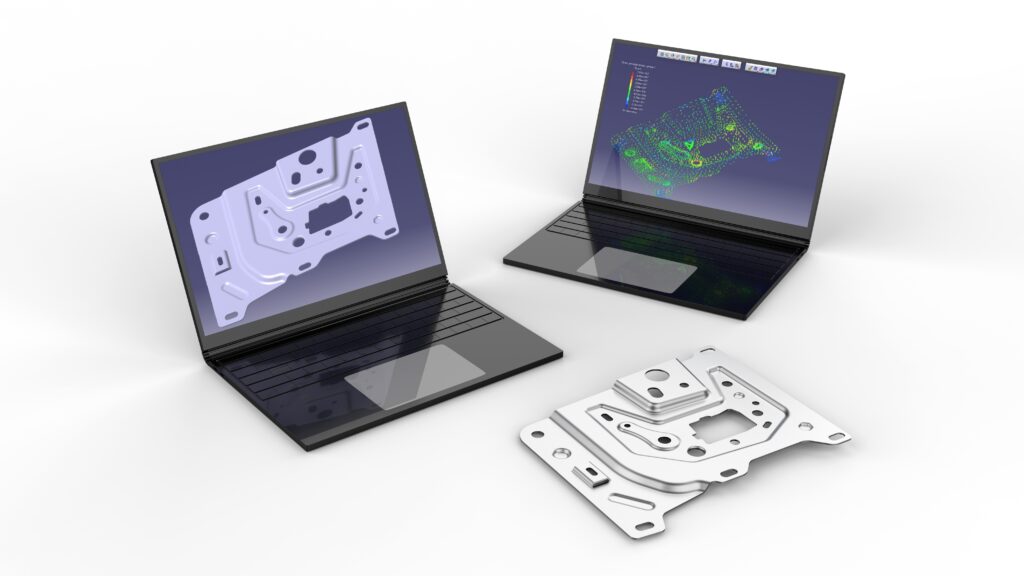

DFM (Design for Manufacturability)

Evaluate if they provide design optimization services to make your products easier and more cost-effective to manufacture. This can save time and reduce production costs.

Prototyping Services

Check if they offer prototyping to validate designs before mass production. Prototyping helps identify and resolve potential issues early.

Why Is Communication and Responsiveness Crucial?

Effective communication and responsiveness are key to a successful partnership. Ensure your fabricator can provide timely updates and support throughout the project.

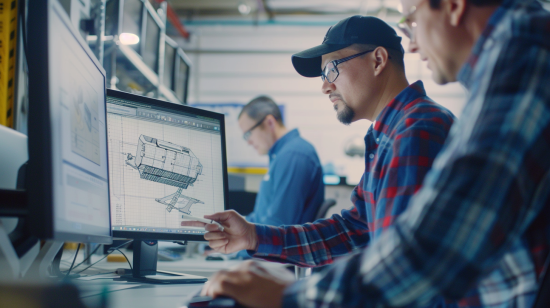

Technical Communication

Ensure they have technical experts who can communicate effectively in English. Clear communication helps prevent misunderstandings and errors.

Customer Service

Assess their responsiveness and willingness to provide ongoing support and updates. A reliable partner will keep you informed and address any concerns promptly.

How to Analyze Cost Efficiency?

Cost efficiency involves finding a balance between quality and price. The cheapest option is not always the best value.

Competitive Pricing

Compare quotes to ensure competitive pricing without sacrificing quality. Consider the overall value provided, including service and reliability.

Cost-saving Recommendations

Find a partner that gives you ideas to save money on materials or how you make parts. This can save you a lot of money in the long run.

What About Delivery and Logistics?

Timely delivery and effective logistics are crucial for maintaining project schedules and avoiding delays.

Timely Delivery

Confirm their track record for on-time deliveries. Reliable delivery schedules keep your project on track and within budget.

Packaging Standards

Ensure their packaging methods prevent damage during transit. Proper packaging protects your investment and ensures parts arrive in good condition.

Why Is After-Sales Support Important?

After-sales support ensures long-term satisfaction and addresses any post-production issues that may arise.

Warranty and Returns

Check their policies on warranties, returns, and handling defects. A good partner will stand by their work and provide necessary support.

Long-term Partnership

Consider their potential as a long-term partner who can grow with your business. Building a strong relationship with a reliable fabricator pays off in the long run.

Understanding Metal Fabrication and Its Importance

Metal fabrication involves shaping, manipulating, and assembling metals to create various products and structures. It is essential for creating durable, precise, and reliable products across multiple industries.

Versatility and Precision

Metal fabrication techniques like cutting, bending, welding, machining, and finishing transform raw metal into desired shapes. This versatility makes it indispensable for modern engineering and design.

Industry Applications

From automotive and aerospace to medical and consumer products, metal fabrication is crucial for producing high-quality components and assemblies.

How Does Reputation and Experience Play into Your Decision?

Reputation and experience are important factors to consider when choosing a fabricator.

Reputation in the Industry

Find a company that’s well-known in your industry and has a track record of doing good work. When a company has a good reputation, it usually means they make good parts and keep their customers happy.

Years of Expertise

An experienced partner like Premium, with over 20 years in the industry, has a lot of knowledge and expertise. That experience means they can make your parts with accuracy and professionalism.

What Certifications and Accreditations Are Essential?

Certifications and accreditations demonstrate a fabricator’s commitment to quality and industry standards.

Quality Standards

Partner with fabricators who have certifications such as ISO:9001, AS9100D, IATF16949,ITAR, and RoHS. These certifications ensure compliance with rigorous quality and safety standards.

How Do Supply Chain Operations Impact Your Project?

Efficient supply chain operations are crucial for timely and cost-effective project completion.

Efficiency and Reliability

Choose a partner with a well-managed fabrication process to avoid delays and downtime. Reliable supply chain operations enhance overall project efficiency.

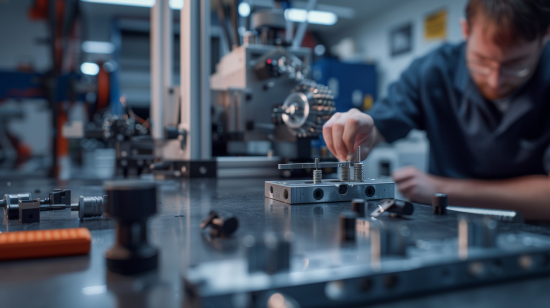

What Facilities and Capabilities Should You Look For?

The facilities and capabilities of a fabricator determine their ability to handle your project’s size and complexity.

Advanced Facilities

Ensure the fabricator has the facilities and technology to manage projects of varying sizes and complexities. Advanced infrastructure supports high-quality production.

Wide Range of Capabilities

Look for a company capable of performing various services such as cutting, punching, forming, machining, welding, grinding, finishing, assembly, and quality assurance. A wide range of capabilities ensures they can meet all your project needs.

Why Is Industry Familiarity Important?

A fabricator familiar with your industry understands the specific quality standards and practices required.

Specific Industry Knowledge

Work with a fabricator who has experience in your industry, whether it’s construction, medical devices, food service, cabinetry, HVAC, or another sector. They will be more aware of potential issues and provide valuable insights.

Design and Production Suggestions

Experienced partners can offer design and production suggestions to improve your project based on their industry knowledge. This expertise can lead to better outcomes and higher efficiency.

How to Gauge Customer Satisfaction?

Customer satisfaction provides insight into a fabricator’s reliability and quality of service.

Portfolio and Testimonials

Review their portfolio of previous projects and customer testimonials. Look for similarities with your project to ensure they can meet your specific needs.

Direct References

Use your network to get direct feedback from past clients. Online reviews are helpful, but personal recommendations provide deeper insights.

Why Are Customized Solutions Beneficial?

Customized solutions ensure your specific needs are met and can enhance the overall quality of your project.

Tailored Services

Off-the-shelf products might not fit your needs. A fabricator offering customized solutions and continuous improvements will likely enhance your original design and save on rework costs.

DFMA (Design for Manufacturability and Assembly)

Fabricators who incorporate DFMA principles help optimize production, reduce reworks and waste, and save money. This approach ensures your project is completed efficiently and cost-effectively.

What Is the Importance of Employee Tenure?

The stability and expertise of a fabricator’s workforce are crucial for high-quality production.

Long-term Employees

Consider the fabricator’s employee retention. Long-term, experienced workers often indicate a stable and well-managed company, which translates to higher quality work.

Experience of the Production Staff

Ask for details about the production team’s experience and tenure to ensure your project is in skilled hands. Experienced staff are more likely to deliver precise and reliable results.

How Do In-house Capabilities Affect Quality?

In-house capabilities ensure consistent quality and streamline the production process.

Everything Under One Roof

A fabricator that handles everything from design to finishing in-house ensures consistent quality and reduces the need for additional partners. This approach streamlines the process and maintains high standards.

Quality Assurance

In-house production allows for better quality control and accountability throughout the entire project. Consistent oversight ensures that all parts meet your specifications and quality standards.

Why Are Standards and Compliance Crucial?

Adhering to industry standards and compliance regulations ensures quality and safety.

Industry Standards

Verify that the fabricator maintains high standards for quality, efficiency, production, and safety. Third-party certifications like ISO validate their commitment to excellence.

Safety and Efficiency

Ensure they adhere to stringent safety protocols and efficiency standards, which reflect their overall commitment to quality and reliability. High standards ensure that your project is completed safely and efficiently.

How Does Financial Stability Impact Your Project?

A fabricator’s financial health ensures they can handle the scope and scale of your project.

Financial Health

Evaluate the financial health of the company to ensure they can manage additional technologies, expertise, and capacity increases required for your project.

Financially Stable

Ask about their financial practices, including how and when they pay their suppliers. Financial stability ensures they can sustain long-term projects and provide reliable service.

How to Approach Pricing?

Balancing cost and quality is essential for a successful project.

Get Multiple Quotes

Request estimates from multiple manufacturers to find the best balance between cost and quality. The cheapest option is not always the best value.

Pricing Isn’t Everything

Consider the overall value provided, including quality, service, and reliability, rather than focusing solely on price. A higher upfront cost can lead to long-term savings through better quality and efficiency.

Why Is Customer Service Important?

Strong customer service is the foundation of a long-term partnership with a metal fabrication company.

Communicate Regularly

Choose a partner who values customer service, providing regular updates and maintaining open lines of communication. Proactive communication helps prevent misunderstandings and ensures smooth project progress.

Consistent Support

Ensure they offer consistent support throughout the project, from initial design to final delivery. This ongoing support fosters a strong, long-term partnership and ensures project success.

Conclusion

When you’re selecting a sheet metal fabrication partner, you need to look at their technical capabilities, quality control processes, production capacity, design support, communication, cost efficiency, delivery reliability, after-sales support, industry knowledge, customer satisfaction, custom solutions, employee tenure, in-house capabilities, standards and compliance, financial stability, pricing, and customer service. If you consider all of these factors, you’re going to have a successful relationship and work with someone like us at Premium who can meet your needs and deliver high-quality results.