Having trouble designing the perfect sheet metal enclosure for your project? You’re not alone. Many engineers and designers struggle to design enclosures that are both functional and look good. But with the right tips and best practices, you can learn how to design sheet metal enclosures like a pro and make your project a success.

To design a great sheet metal enclosure, you need to understand what your product needs, use the right materials, design it so it’s easy to make, and include important things like tolerances, bend radii, and surface finishes. If you do these things, you can make an enclosure that’s both functional and good looking.

Designing a good sheet metal enclosure is about more than just cutting and bending metal. It involves planning, attention to detail, and considering things like what material to use, how to make it, and how to keep it cool. In this article, we’ll talk about how to design sheet metal enclosures that are efficient, safe, and last a long time. Let’s get started and talk about how to design a great sheet metal enclosure.

Why Are Well-Designed Sheet Metal Enclosures Important?

Sheet metal enclosures are used in numerous industries, including automotive, electronics, and industrial equipment. They protect sensitive components from the environment, provide structural support, and contribute to the aesthetics of the product. A poorly designed enclosure can lead to functional problems, increased production costs, and even safety hazards. Therefore, it’s essential to spend time designing a robust, efficient enclosure.

Understand the Functional and Aesthetic Requirements of Your Product

Size and Layout

• Figure out how to lay out the components. Whether you’re putting a simple PCB inside or a bunch of rack-mounted electronics, the size and how things fit inside are critical.

• Example: For an enclosure that holds a complicated electronic system, figure out how to lay out all the internal components so you use the space efficiently and can get to everything easily.

Features

• Include any mounting features you need, like holes, slots, tabs, or shelves.

• Plan for cutouts for switches, lights, controls, wires, or fluid tubing. If you need to mount the enclosure on a wall, make sure you can mount it easily.

• Example: For a control system enclosure, you might have to cut out a bunch of holes for switches and indicators, as well as put in some internal mounting tabs to hold the circuit boards.

Access

• Determine if you need regular access to the components, which might require doors, removable panels, or windows.

• Example: You might need a removable panel for an enclosure that holds equipment you have to maintain often.

Strength and Rigidity

• Figure out how rigid it has to be. Decide if the enclosure must support heavy loads or if it will be put somewhere with a lot of shock and vibration.

• Example: If you have an industrial enclosure that needs to support heavy equipment and handle a lot of vibration, you have to design it and pick materials that can handle it.

Ventilation

• Figure out if your components need ventilation or if they need to be cooled or heated.

• Example: Electronics enclosures often need to be ventilated to dissipate heat and keep the components at the right temperature.

Environment

• Figure out where you’re going to use it. You might need to add external mounting features, seals, or weatherstripping to make it weather-tight. Electrical enclosures might need a NEMA rating.

• Example: Outdoor enclosures need to be weatherproof to protect against moisture and dust.

Aesthetics

• Figure out how it looks. It can be subtle, or it can show off what’s inside.

• Example: Enclosures for consumer electronics have to look good and match the design of the product.

Pick the Right Material for Your Sheet Metal Enclosures

Choosing the right material for your sheet metal enclosure is important. The material affects how strong it is, how much it weighs, how well it resists corrosion, and how much it costs. Here are some common materials used in sheet metal enclosures and what you need to know about them:

Steel

• Properties: Carbon steel is strong and cheap, but it needs finishing to keep it from rusting. You can use things like zinc plating, powder coating, or galvanized steel.

• Applications: Good for general-purpose enclosures where you need something strong.

• Example: If you need something stronger, think about using 4130 Chromoly steel. It’s a lot stronger but costs a little more.

Aluminum

• Properties: Naturally resists rust, lightweight, and can be anodized or powder coated. Aluminum is also good at conducting heat, making it great for heat sinks.

• Applications: Great for enclosures where you need something light and that resists rust.

• Example: Premium gives you Type III anodizing, which makes aluminum enclosures tougher and lets you use them outside and inside.

Stainless Steel

• Properties: Doesn’t rust much and doesn’t need anything extra to keep it from rusting, but it costs more than steel.

• Applications: Used in places where you need something that won’t rust, like in medical and food processing equipment.

• Example: People use stainless for its clean look and because it’s tough in tough conditions.

Copper and Brass

• Properties: Conducts electricity and heat well and is good for making things look good or for special electrical things.

• Applications: Used a lot in electrical stuff and for making things look good.

• Example: Copper is used where you need something to conduct electricity well, and brass is used when you want it to look good.

Titanium

• Properties: Super strong, super light, and doesn’t rust. People use it a lot in aerospace, but it costs more.

• Applications: Good for applications where you need something to be super strong but not too heavy.

• Example: People use titanium in aerospace and ships because it’s strong and won’t rust.

Polycarbonate

• Properties: Not metal, but it’s good for making clear enclosures because it’s strong, clear, and doesn’t rust.

• Applications: Used for covers, windows, and enclosures where you need to see inside.

• Example: People use polycarbonate in safety and display enclosures because you can see through it, and it’s tough.

Advanced Material Considerations

• Specialty Alloys: If you need something super strong or that does something special, think about using specialty alloys. They work better, but they cost more.

• Composite Materials: Sometimes, composite materials are better because they’re lighter, stronger, or tougher. They are good for aerospace and cars.

• Environmental Impact: Think about the environment when you pick your materials. Things like aluminum and stainless steel are easy to recycle, which is good for people who care about the environment.

Design for Manufacturability (DFM)

For a cost-effective, easy-to-manufacture sheet metal enclosure, follow these DFM tips:

Minimize Complexity

• Simplify your design to reduce the number of operations and parts. This reduces the potential for mistakes and speeds up production.

Standardize Components

• Use standard hardware and components whenever you can. This helps streamline manufacturing and lowers costs.

Consider Manufacturing Processes

• Remember processes like cutting, bending, and welding when you design. Using standard sheet sizes can reduce waste and cut costs.

Practical DFM Tips

• Tool Access: Make sure your design allows for easy access to tools during manufacturing. This can speed up production and lower costs.

• Automation Compatibility: Design parts that work well with automated manufacturing. This helps make production more efficient and consistent.

• Material Utilization: Design your parts to use material efficiently. This cuts down on waste and makes your parts more cost-effective.

Take Dimensional Tolerances into Consideration

Specifying the correct tolerances is critical to ensuring your enclosure fits and works correctly. Tight tolerances can improve fit but can make manufacturing more complicated and expensive. Work with your manufacturer to find the right tolerances for your design.

Tips for Tolerances

- Functional Tolerances: Use tight tolerances only where you need to.

- Cost Implications: Remember that tighter tolerances cost more money. Work with your manufacturer to make sure you’re not paying too much.

- Consistency: Make sure your tolerances are the same all over your design so you can put it together easily.

Mind the Bend Radius

Making sure you have the right bend radii is important to keep your material from cracking and make your parts look good. Use bend reliefs so you don’t put too much stress on the material, which can make it deform. Premium gives you all the information you need about bend radii, k-factor, and other bending stuff for each material and thickness on their materials pages.

Bend Tips

- Material Properties: Different materials bend differently. Make sure you know how your material bends.

- Bend Direction: Make your bends go with the grain of the material whenever you can so it doesn’t crack.

- Precision: Use good bending tools and techniques to make sure your bends look good and work right.

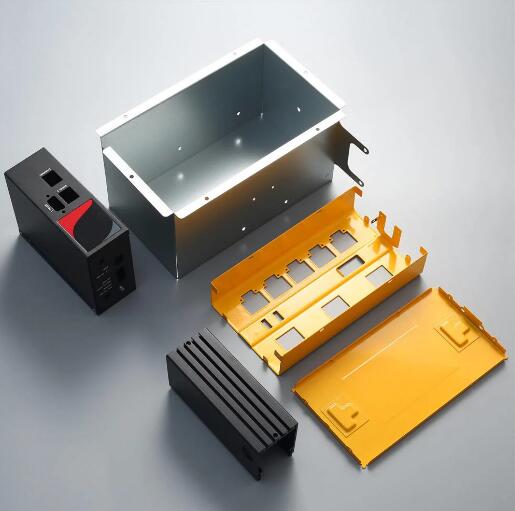

Decide How the Enclosure Will Be Assembled

Picking the right way to put your enclosure together is important. The way you fasten and join the parts can make a big difference in how strong, reliable, and good looking your enclosure is:

Welding

• Good for sealed enclosures because it makes them look nice and smooth.

Rivets

• Used a lot to hold panels together. You have to drill holes in the panels and make sure you line them up right.

Threaded Fasteners

• You can use screws, nuts and bolts, or PEM fasteners. PEM fasteners are easy to use but take more time to install.

Advanced Fastening Techniques

• Adhesive Bonding: Sometimes you can use glue instead of screws or rivets to put your parts together. This can make really strong, long-lasting joints.

• Hybrid Joints: You can use more than one fastening method, like welding and riveting, to make your enclosure stronger and more reliable.

• Disassembly: If you have to take your enclosure apart a lot, make sure you pick fastening methods that let you do this without breaking your enclosure.

What Kind of Finish Does Your Product Need

How you finish your enclosure helps it last longer and look better. Here are some things to think about:

Mechanical Finishes

• You can polish or brush materials like aluminum, stainless steel, copper, and brass.

Protective Finishes

• For steel, you can use powder coating or zinc plating. For aluminum, you can use anodizing. Type III anodizing is a more durable finish.

Finishing Techniques

• Electropolishing: This makes metal look better and helps it resist rust. People use it a lot on stainless steel.

• Ceramic Coating: This makes metal tough and able to handle high temperatures.

• Decorative Finishes: If people are going to see your enclosure, make it look nice with a special finish.

Optimize for Manufacturing Efficiency

Here are some ways to make it easier to make your enclosure:

Minimize Complexity

• Make your designs simpler. This means fewer steps and parts. This helps avoid mistakes and speeds up production.

Standardize Components

• Use the same hardware and components as much as you can. This makes it easier to make your enclosure and costs you less money.

Efficiency Enhancements

• Lean Manufacturing: Use lean manufacturing ideas to cut waste and make things go faster.

• Process Automation: Use robots and machines to do things that are easy but take a long time. This makes things go faster and be more the same every time.

• Continuous Improvement: Keep looking at how you make your enclosures to make them better all the time.

Plan for Assembly and Disassembly

Making your enclosure easy to put together and take apart can save you time and money:

Easy Assembly

• Make sure your enclosure goes together quickly and easily. You can use self-clinching fasteners or captive hardware to save time.

Maintenance Access

• Make sure you can take your enclosure apart easily to fix it or change it without breaking it.

Assembly Tips

• Modular Design: Make your enclosure in pieces so it’s easy to put together and take apart.

• Tool-Free Assembly: Make your parts so they go together without tools. This makes it faster and less likely you’ll break something.

• Documentation: Give people good instructions so they can put your enclosure together right the first time.

Incorporate Safety Features

Keep safety in mind when you design your enclosure:

Edge Treatments

• Make sure you take off any sharp edges and corners so people don’t get cut when they touch your enclosure.

Ventilation and Heat Dissipation

• Make sure air can get in and out so your parts don’t get too hot. Use louvers, vents, or mesh where you need them.

More Safety Ideas

• Locking Mechanisms: If you need to keep your enclosure locked up, make sure you have a way to lock it so people can’t get in.

• Labeling: Put labels on all the parts so people can put them together right and use them safely.

• Ergonomics: Design your enclosure so it’s easy to pick up and move without hurting yourself.

Why Use Sheet Metal Enclosures?

People use sheet metal enclosures for all kinds of things because they are great in all these ways:

- Advantages: Cost-effective, lightweight, simple to fabricate, and customizable for specific features like windows, switches, ports, and more.

- Applications: Protect electrical components, display collectibles, contain fluids, and more.

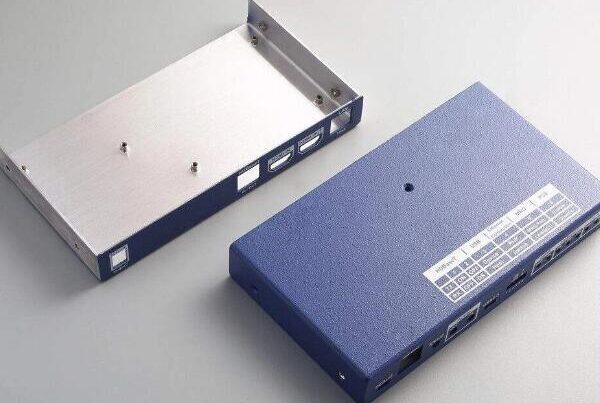

Sheet Metal Enclosures and Housing Fabrications

Premium is great at making custom sheet metal enclosures and housing for electronics. We know that a lot of industries need things that are made just right. Our team of people who do sheet metal stuff, run lasers, and write programs are really good at making sure you get what you need fast and at the right price. Big companies all over the world trust us to make their things. You can see why when you ask us for a price.

Conclusion

Designing sheet metal enclosures involves planning and paying attention. If you understand what you need, pick the right materials, and put in the right things, you can make your enclosure look good and work right. If you work with Premium, you get to use the best machines and have people who know how to help you pick the right things and make them. Contact us so we can help you make your next sheet metal thing.