You’ve been there, right? Excitement builds as your sheet metal project progresses, only to hit a roadblock during production. Maybe the design wasn’t feasible, or the materials didn’t perform as expected. The result? Delays, frustration, and wasted resources. But what if you could avoid all that right from the start?

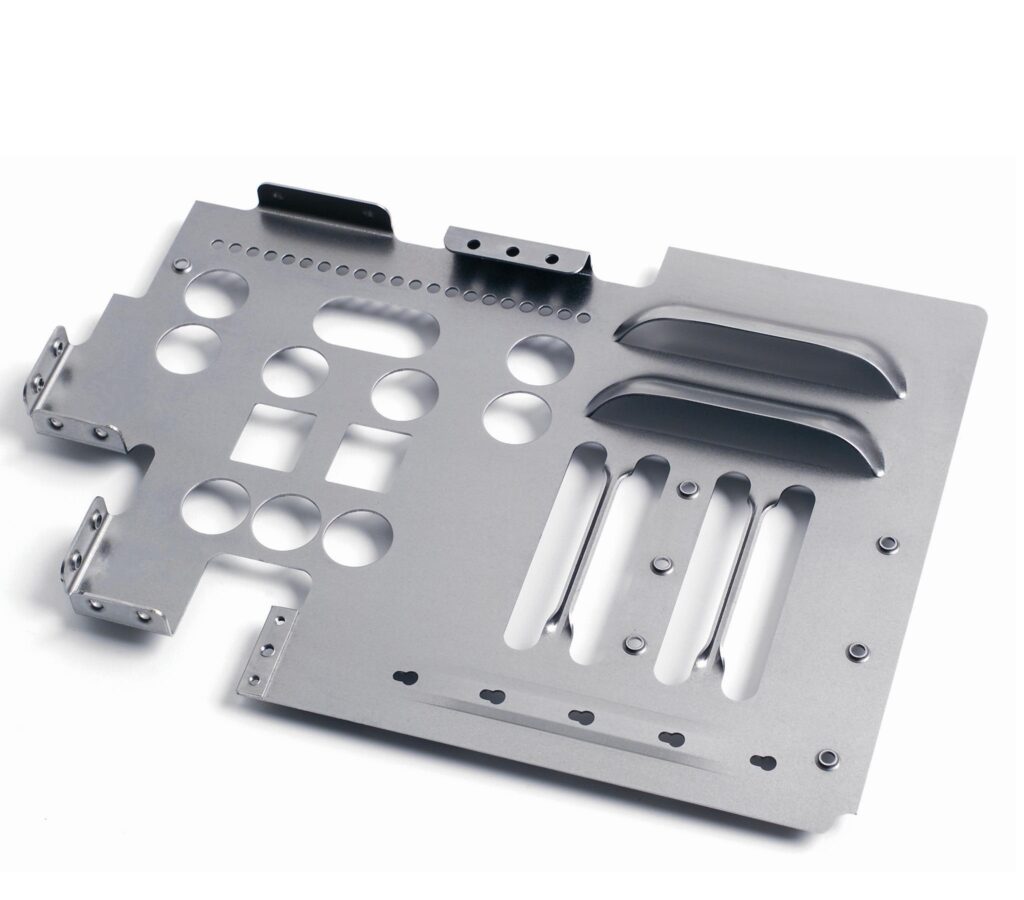

Prototyping ensures the success of sheet metal projects by identifying design flaws early, reducing manufacturing risks, optimizing materials and processes, and confirming that the final product will meet functional and performance requirements. This pre-production step leads to cost savings, faster production, and a higher quality outcome.

Sounds great, doesn’t it? Let’s dive deeper into how prototyping can truly transform your sheet metal projects from concept to completion.

How to Turn What’s on Paper into Reality and Lower Your Risk

Have you ever looked at a drawing on paper and said, “This is perfect!” and then you made it and it wasn’t? That’s what prototyping does. It takes what’s in your head and makes it real, so you can see how it works. You’re not guessing if it will work. You’re testing it with your hands.

When we make prototypes, we figure out what doesn’t work with the design or what’s not going to work when we try to make it. We figure that out before we make a thousand of them. We figure that out before the cost is 10 times higher and the stakes are 10 times higher.

How to Make Projects Go Faster and Improve Your Product Design

Have you ever had a project that was late? It costs you a lot of money. Prototyping helps you with that. When you show something to a customer, they make decisions fast. You get feedback fast. You make changes fast. You make things fast. It’s like the fast lane to success without the speed traps.

Prototyping lets you get the design right before you make a bunch of them. It’s not just about making sure all the parts are there. It’s about making sure every part of the design is the best it can be for making it (DFM). Does it work like it’s supposed to? Is it easy to put together? You find out fast, so you can feel good about moving forward.

How to Pick the Right Materials and Processes

Now, let’s talk about materials. Have you ever wondered if the metal you use is the best metal for your project? Prototyping helps you with that. With prototypes, you can try different materials to see how they work in real life. Choosing the right material when you prototype will save you a ton of money when you make it and make it work better and last longer.

You can also try different ways to make your part. Whether you’re going to laser cut it, stamp it, or weld it, prototyping lets you choose the best way to make your design the best it can be. It’s like a practice run for the real thing.

How to Get Your Customers on the Same Page

When was the last time you said, “I wish I would have known that earlier?” Prototyping fixes that. It’s a team tool that makes sure everybody—designers, engineers, and customers—knows what’s going on. The physical prototype becomes a place to talk about what you want. It gets everybody on the same page. No more misunderstandings. No more surprises.

When you see a prototype that works, it builds confidence for you and your customers. They see what they want coming to life, and they don’t worry about where it’s going. That confidence helps everybody know what it’s going to look like and how it’s going to work.

How to Transition from Prototype to Production

Have you ever had a project that went from prototype to production and, all of a sudden, it wasn’t as easy as you thought it was going to be? Prototyping helps you not have that happen. By getting the stamping tools or molds right during the prototype stage, we make sure that when you make a million of them, it’s as easy as possible. No problems.

It also lets us know how to scale. We know all the things that are going to be problems—machinery, tooling, assembly—early. We adjust them before they become a big problem. Why wait until later when you can make it smooth now?

How to Make Changes and Test

Do you need your sheet metal project to be a little more special? Maybe it’s an aerospace part that has to be perfect, or it’s a medical device housing that has to be just right. Prototyping lets us make a lot of changes to see if we can get the part to do exactly what you want it to do.

We know that in industries where you have to be perfect, where you have to be right, you have to be right. You have to be able to make changes as you go. You have to be able to make it perfect.

How to Get It Done Faster and Get More Certifications

Are you worried about certifications? Prototyping helps with that too. Whether your project is going to the car business or the airplane business, it needs to be certified. Using prototypes for early certification helps you get through the process faster and get to market faster.

More than that, safety and durability testing in the prototype stage helps make sure your product is going to work. Can it take the stress? Will it work the way it’s supposed to? Early prototyping can save you a lot of time getting your product through the process and make sure you pass all the tests you need to pass.

How to Be Green and Save Money

Let’s talk about being green. Do you want your project to be as good for the world as possible? Of course you do—it’s better for the planet and it’s better for your pocketbook. Prototyping helps you figure out where you’re wasting material, where you’re wasting time, and where you’re wasting resources. It’s like cutting the fat before you get to the meat.

But it also helps us try green materials to make sure they work for you and meet all your requirements without giving up performance. You get a better product, and you get to sleep better knowing you’re doing your part for the world.

How to Make Your Product Feel Good

Have you ever thought about how your product feels to the person who uses it? Prototyping helps with that too. If your sheet metal part is something somebody is going to pick up, like a box, a handle, or a housing, you want it to feel good and fit well in their hand.

Prototyping lets you try that stuff early to make sure your product is comfortable and easy to use. It’s about making it look good and work good. What good is a great product if it’s hard to use?

Conclusion

In sheet metal projects, prototyping isn’t just something you can do—it’s something you have to do. It helps you take risks out of the process, make your design better, work better with people, and get it right the first time. Ready to prototype your next project so you can be successful? Let’s do it.