Need a cover for your stuff, but can’t find one that fits? Custom sheet metal covers might be the answer. They fit better, last longer, and can be made to do exactly what you want. At Premium Rapid & Mold, we make great custom sheet metal covers for a bunch of different industries. We’d love to make some for you, too!

Custom sheet metal covers make your business better because they fit better, last longer, and work better. They’re made to do exactly what you need them to do. Whether you work in automotive, electronics, or some other industry, custom covers are the way to go.

Let me tell you how custom sheet metal covers will make your business better. We’ll talk about the materials, how we make them, how we finish them, how we make sure they’re awesome, and how they can do exactly what you need them to do. By the time you finish this article, you’ll know why the best companies in the world trust Premium Rapid & Mold to make their sheet metal covers and how you can make them work for your business.

Why Choose Custom Sheet Metal Covers?

Custom sheet metal covers do something that off-the-shelf covers can’t. They do exactly what you want them to do. They fit perfectly. They protect your stuff better. Whether you work in automotive, electronics, or some other industry, we make covers that fit great, work great, and hold up great.

Material Selection for Sheet Metal Covers

The material selection process involves considering factors like durability, corrosion resistance, and cost to ensure the covers meet your specific requirements.

Choosing the right material for your sheet metal covers is crucial to their performance and how long they last. We use different materials at Premium Rapid & Mold, and each one is chosen for different reasons and different applications:

• Aluminum: Light and won’t rust. Good for when you’re trying to save weight.

• Stainless Steel: Won’t rust, tough as nails, and works great in tough environments.

• Mild Steel: Cheap and can be used for a lot of different things.

When we choose the material for your covers, we think about how long you need them to last, where you’re going to use them, and how much you want to spend.

Fabrication Process for Sheet Metal Covers

Our skilled team of sheet metal mechanics, laser operators, and programmers ensures that every step of the fabrication process is carried out with precision and attention to detail.

Here at Premium Rapid & Mold, we have a lot of steps to make sure you get great custom sheet metal covers:

• Design and CAD Modeling: We start by designing and modeling your covers to make sure they fit.

• Cutting: We cut your covers with lasers, waterjets, and plasma cutters to make sure they’re the right size.

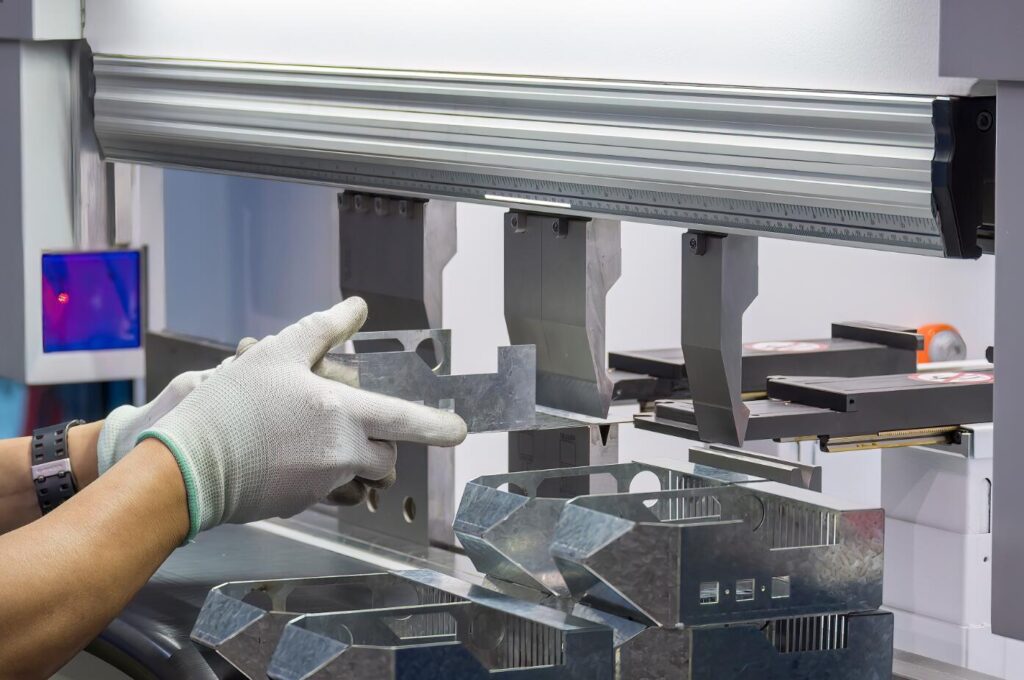

• Forming: We bend, stamp, and roll our metal to make your covers look the way you want them to.

• Joining: We weld, rivet, and screw your covers together so they won’t fall apart.

We have a team of great sheet metal mechanics, laser operators, and programmers who make sure every part of this process is done right.

Surface Treatment for Enhanced Durability

We offer a bunch of treatments to make sure your sheet metal covers last as long as possible:

• Powder Coating: This is the most common way to finish your covers. It’s tough, looks great, and protects your covers from getting beat up.

• Anodizing: This is a way to make your covers last longer and look better. It’s also great if you want your covers to look different colors.

• Plating: We can plate your covers with different metals to make them last longer and look better.

These treatments make your covers look great and last a long time, even when you’re using them in tough places.

Quality Control in Sheet Metal Covers Fabrication

We do a lot of things to make sure you get the best custom sheet metal covers:

• Inspections: We check your covers at every step to make sure they’re great.

• Tests: We do a lot of different tests to make sure your covers last and work.

• Check Consistency: We check your covers all the time to make sure they’re all the same.

Our goal is to make sure that every cover you get from us is perfect, lasts a long time, and doesn’t let you down.

Customization Benefits

The best part about custom sheet metal covers is that you can get exactly what you want. Here’s why that’s so great:

• Fits Perfectly: We make sure your covers fit exactly the way they should so they protect your stuff and make it work better.

• Tailored to You: You tell us how you want your covers to look, what you want them made of, and how you want them finished. We do it all.

• Make Your Stuff Better: Custom covers can make your stuff work better and last longer.

For example, one of our customers saw a 30% improvement in corrosion resistance when they switched to custom anodized covers for their electronic enclosures. This made their product last longer and saved them money on maintenance.

Quick Turn Precision Sheet Metal Fabrication Services

We are known for our fast turnaround precision sheet metal fabrication services. Whether you need one prototype or up to 5,000 parts, we can help. With over 20 years of experience, the latest software, experienced employees, and top-of-the-line equipment, we can help you get your parts right the first time.

We love prototypes. We can do quantity 1 all the way to low-volume production. We can handle whatever you need, quickly and accurately. We work with a lot of different clients. If you need something fast, you need something accurate, you need something done right, we can help. Get a quote today or give us a call and we’ll help you out.

How to Design Sheet Metal Parts for Manufacturing

When you design parts for sheet metal fabrication, you can save money and time. Here are some tips for designing parts for sheet metal fabrication:

• Hems & Offsets: Make sure your edges are safe and add strength.

• Notches & Tabs: Use them for alignment and better fits.

• Corners & Welds: Think about how strong your part needs to be and how it looks.

• Consistent Thickness: Keep your metal the same thickness or you’re going to have problems.

If you follow these tips, you’ll get better results and it will be easier for us to make your parts.

The Challenges and How We Solve Them

When it comes to making custom sheet metal covers, there are some things we have to deal with that you probably don’t care about. Here are a few of them and how we make sure we take care of them:

• Material Wastage: We use the most advanced equipment and the most efficient process to keep this to a minimum.

• Tight Tolerances: We use the best equipment and the best people to make sure we hit the numbers you need us to hit.

• Surface Finish: We have a lot of special treatments and a lot of quality control to make sure your covers look great every time.

We do all this stuff so you can get great covers that last a long time.

Conclusion

Custom sheet metal covers are the way to go. They work better, last longer, and do exactly what you want them to do. We make great custom sheet metal covers that work for a lot of different industries. If you need covers, we’re here to help. Get a quote and let us show you what we can do for you.