Are you struggling to figure out the best practices for stainless steel sheet metal fabrication? You’re not alone. This is something that a lot of people struggle with. A lot of businesses struggle to get high-quality, cost-effective fabrication. The good news is, there are proven ways to make your fabrication process better, get consistent results, and save money. Let’s talk about the best practices to help you make your stainless steel sheet metal projects better.

The best practices for stainless steel sheet metal fabrication include choosing the right alloy, using design-for-manufacturing (DFM) principles, using the right tools, and making sure you have a good quality control process. By doing these things, you’ll be able to make your production process more efficient, get better finishes, and save money. This will make your fabrication projects more successful and reliable.

It’s important for any business that is in manufacturing to know the best practices for stainless steel sheet metal fabrication. It will help you figure out the best way to work with stainless steel, which is a great material, but can be a pain to work with. By following these guidelines, you will be able to make your production processes more efficient, make your final products better, and make your customers happier.

What is Stainless Steel Sheet Metal Fabrication?

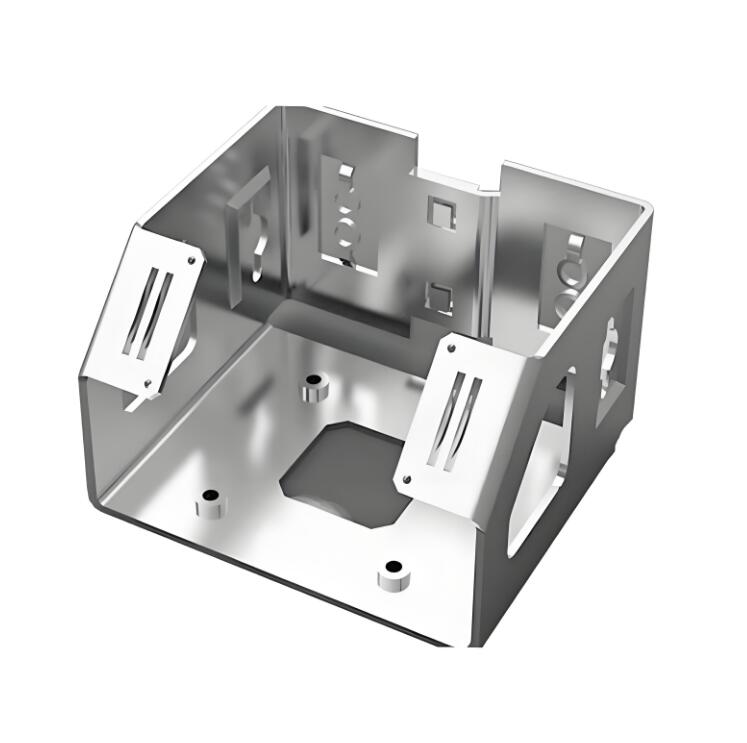

Stainless steel sheet metal fabrication is the process of forming stainless steel into the desired shapes. This includes cutting, bending, forming, welding, and finishing. The 300 series alloys, such as 301, 304, and 316, are the most popular grades for fabrication because they are formable, ductile, and corrosion-resistant.

Types of Stainless Steel Used

| Property | Stainless Steel 301 | Stainless Steel 304 | Stainless Steel 316 |

| Tensile Strength, Yield | 205 MPa | 215 MPa | 290 MPa |

| Fatigue Strength | 240 MPa | Not specified | Not specified |

| Shear Modulus | Not specified | 77 GPa | 74 GPa |

| Elongation at Break | 40% | 70% | 50% |

| Hardness (Brinell) | 217 | 123 | 217 |

| Density | 8.03 g/cm³ | 8 g/cm³ | 8 g/cm³ |

Best Practices for Stainless Steel Sheet Metal Fabrication

1. Choose the Right Alloy

The first thing you need to do is to choose the right stainless steel alloy for your application. Different stainless steels offer different levels of corrosion resistance, strength, and cost. For example, while 304 is a very versatile and commonly used alloy, 316 is a better choice for harsh environments because of its superior corrosion resistance. Making sure your material is appropriate for the specific environmental conditions and functional requirements can have a huge impact on your costs and performance. Chemical compatibility charts can help you make informed decisions about material selection.

2. Follow Design-for-Manufacturing (DFM) Principles

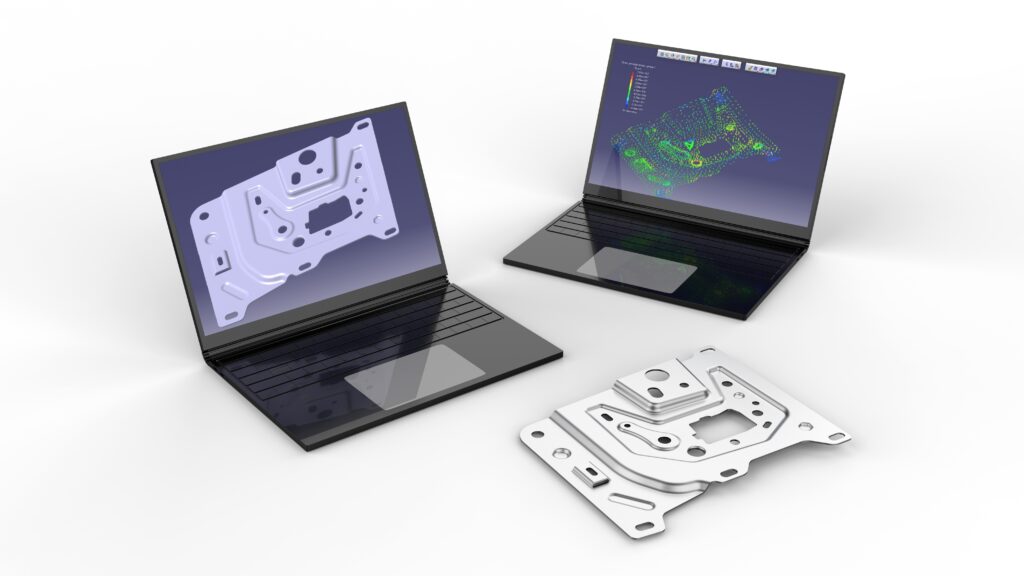

Designing for manufacturing (DFM) is essential to optimizing your fabrication process. This means designing parts that are easy to manufacture and assemble, and avoiding complex shapes that are difficult to make. Using tools like CAD/CAM software helps you create accurate designs that adhere to these principles.

3. Employ Advanced Technological Tools

Using advanced machinery and automation technology will make your fabrication process more efficient and accurate. Laser cutting machines, CNC bending machines, and robotic welding systems ensure you get high precision and consistency in your production.

4. Implement Rigorous Quality Control Measures

Quality control is important to making sure your stainless steel parts are reliable and durable. Regularly inspecting and testing for defects, maintaining tight tolerances, and adhering to industry standards are all important practices. You can also use advanced techniques like non-destructive testing (NDT) to detect internal flaws without damaging your parts.

5. Optimize Surface Finishes

Surface finishes are important for improving the appearance and functional properties of stainless steel. Some options include:

- Standard Finish: The part remains in its original state post-bending and forming. Pickling and passivation ensure uniform properties.

- Powder Coating: Adds a robust surface finish, improving anti-corrosion properties.

- Bead Blasting: Provides a smooth, matte finish for cosmetic purposes.

- Brushing: Creates a linear texture for aesthetic appeal.

- Polishing: Achieves a mirror-like finish for high reflectivity and smoothness.

- Passivation: Enhances corrosion resistance by removing surface contaminants.

Common Challenges in Stainless Steel Fabrication

Despite its many advantages, stainless steel poses several challenges during fabrication:

- Handling and Processing Difficulties: Stainless steel is hard, so it can be hard to cut and shape.

- Maintaining Consistency in Surface Finishes: It’s hard to get the same finish on multiple parts.

- Managing Material Costs and Waste: Stainless steel is expensive, so you have to be efficient with it to not waste it.

- Ensuring Precise Tolerances and Quality Control: You have to be precise to make sure your parts meet the design specs and do what they’re supposed to do.

Technological Advancements in Stainless Steel Fabrication

There are a lot of ways to deal with these problems:

• Use Better Machines and Tools: Laser cutters and CNC benders are really precise.

• Use Automation and Robots: Robots help you be more efficient and consistent.

• Use CAD/CAM Software: It helps you design things accurately and simulate them so you make fewer mistakes in fabrication.

Industries We Serve

We work with a lot of different industries:

- Automotive: Used for exhaust systems, body parts, and structural components.

- Medical Equipment: Ideal for surgical instruments, implants, and hospital equipment due to its sterility.

- Consumer Electronics: Used in enclosures, brackets, and internal components.

- Industrial Applications: Essential for machinery, tools, and structural parts.

- Aerospace: Used in aircraft components, offering high strength-to-weight ratios.

- Household Appliances: Common in kitchen appliances, offering durability and aesthetic appeal.

- Lighting and Audio Facilities: Provides structural and aesthetic solutions.

- Power Distribution Equipment: Essential for enclosures and structural components in power systems.

- 5G Equipment: Used in enclosures and mounting systems due to its durability.

Our Process for Stainless steel Sheet Metal Fabrication

Consultation and Design

We start by talking with you to figure out what you need. We talk about what you want to do, what you like, and what you need to do. Our engineers help you make your design better. This makes sure that we can do what you want and that it will work.

Material Selection and Recommendations

Picking the right material is really important. We help you pick the right stainless steel alloy for what you’re doing. We help you figure out what you need to use based on how strong it needs to be, how much it costs, and what you’re going to do with it. We help you understand what the material is like and how to use it so that your part works great and lasts a long time.

Prototype Development

Before we make a lot of parts, we make a few to make sure they work. We make a few parts to test and look at. This helps us find problems early. We can make changes and make sure that the part does what you need it to do.

Mass Production

Once we know the part works, we make a lot of them. We use machines that are really good at making a lot of parts at once. We use lasers to cut the parts, and machines to bend them, and robots to weld them. This makes sure that we can make a lot of parts that all work great.

Quality Control and Inspection

Making sure the parts are good is really important. We look at the parts and test them all through the process to make sure they’re good. We use special tests to make sure the parts are good and that they work the way they’re supposed to.

Packaging and Delivery

It’s important to wrap your parts up so they don’t get hurt when they’re shipped. We pack things up good so they don’t get hurt and so they get to you in good shape. We have a team that makes sure your parts get to you when you need them and tells you when they’re coming so you know they’re on the way.

Cost-saving Design Tips

Pick the Right Stainless Steel

This is the biggest thing you can do to save money. Pick the right stainless steel for what you’re doing. Make sure the material works for where you’re going to put it and what you need it to do. Use the chemical compatibility charts to help you pick the best material for your part.

DFM (Design-for-Manufacturing)

This is really important. Make sure your part is easy to make. Don’t make your part too hard to make. Don’t put weird stuff on your part that makes it hard to make. Use our sheet metal design guide to help you make your part so we can make it easy.

Material Efficiency

Make sure you use all of the stainless steel. Don’t waste it. Put as many parts on a piece of stainless steel as you can. This will help you save money and make more parts. Look at your part and make sure you use all the stainless steel you can.

Why Choose Us?

At Premium Rapid & Mold, We’ve been doing this for a long time and we’re really good at it. Our team of engineers has been doing this for over 8 years. We can help you with everything from design to making a lot of parts. We work to make sure your design is easy to make so we can give you a good price and make sure the parts are good.

Contact Us

Are you ready to make your stainless steel parts with us? If so, let’s talk about what you need and how we can help you. We can give you a price and talk about how we can help you make your parts.

Conclusion

By doing these things, you’ll get good parts that don’t cost a lot of money. It doesn’t matter if you’re making car parts, medical parts, or anything else. If you do these things, you’ll make good parts and people will like them.