In today’s world of competitive manufacturing, you need to be precise, fast, and cost-effective. Everyone is looking for ways to get better. One technology that is getting a lot of attention is laser cutting sheet metal. Like all other technologies, it has pros and cons. Understanding these will help you decide if it can help you.

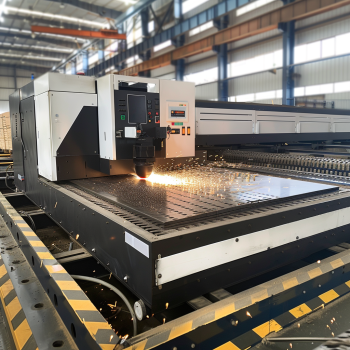

Laser cutting sheet metal is a high-precision process that uses a high-powered laser to cut sheet metal into the shapes and sizes you want. It is fast, very accurate, and versatile. It is used in many industries, including automotive, aerospace, and consumer electronics. Even with the high cost of entry and some material limitations, the benefits often outweigh the drawbacks because it is efficient and produces high-quality results.

To keep you interested, we will explore the world of laser cutting in more depth. We’ll discuss the history of laser cutting, the types of lasers used, and the advantages and disadvantages in detail. We’ll also talk about the process, the things you need to think about, and the safety precautions you need to take. Whether you are in the automotive, aerospace, or consumer electronics industry, this guide will help you understand how laser cutting can help you.

What Is Laser Cutting Sheet Metal?

Laser cutting sheet metal is a precision manufacturing process that uses a high-powered laser to cut sheet metal into the shapes and sizes you want. You focus the laser on the material, which melts, burns, or vaporizes, leaving you with a nice, clean cut. It is used in many industries because it is accurate and fast.

Types of Lasers

• CO2 Lasers: CO2 lasers are good for non-metallic materials and thicker metals.

• Fiber Lasers: Fiber lasers are more efficient and are good for cutting thin metals and reflective materials.

The History of Laser Cutting Sheet Metal

Lasers were invented in 1960 by Theodore Maiman. However, laser cutting wasn’t introduced as a manufacturing process until the 1970s. In the 1980s, CNC (Computer Numerical Control) laser cutting machines were developed, which greatly improved the precision and the automation of the process. In the 2000s, fiber laser technology was developed, which revolutionized the process, making it faster and more accessible.

The Process of Laser Cutting

Preparing CAD Files

The first step in the process of laser cutting is preparing the CAD (Computer-Aided Design) files. These digital files are important because they contain the detailed designs that will be cut into the sheet metal. Here’s how it works:

- Create the Design: The engineers or designers create detailed 2D or 3D models of the part or component.

- Convert the File: These designs are then converted into code that the machine can read. This code is typically in the form of a DXF or DWG file.

- Simulate: Before you actually start cutting the part, you may want to run a simulation to make sure that the design can be cut efficiently and without errors.

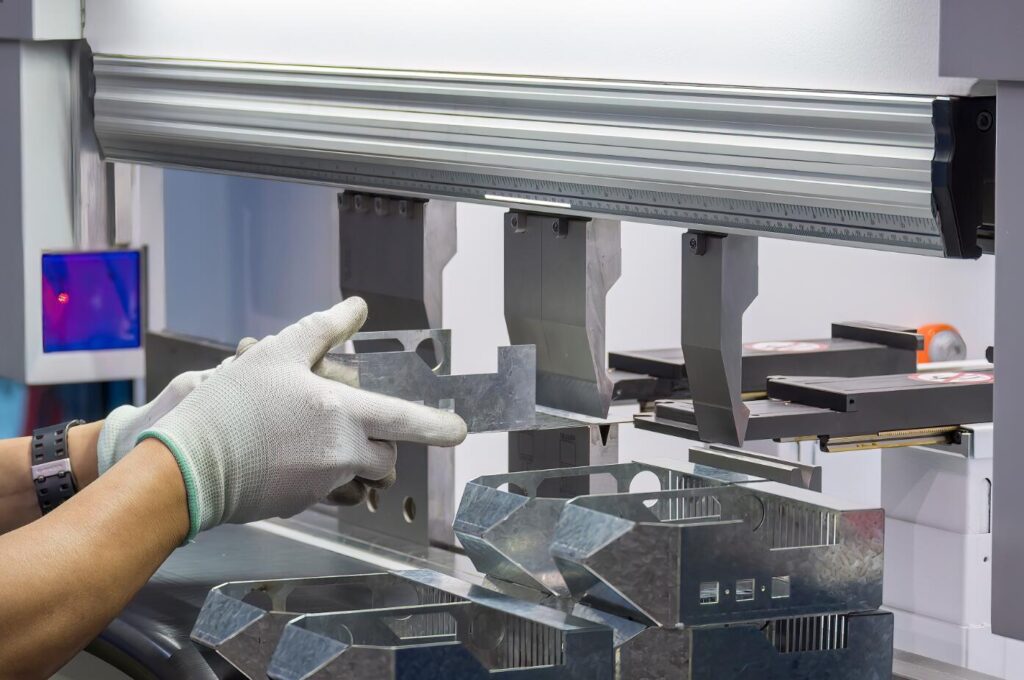

Set Up the Material and Calibrate the Machine

Once you have the CAD files ready, the next step is to set up the material and calibrate the machine: - Align and Secure the Sheet Metal: You put the sheet metal on the cutting bed and secure it. It is essential to make sure that the material doesn’t move while you’re cutting it.

- Calibrate the Laser: You need to make sure that the laser beam is focused correctly and that the settings on the machine are correct for the type and thickness of the material you’re cutting. This is important to get a good cut.

Execution of the Cutting Operation

With everything set up, you can start cutting:

- Start the Cut: You turn on the laser, and the head starts to follow the path you defined in your CAD file.

- Watch the Cut: You watch the cut to make sure it is cutting where it is supposed to. You make adjustments in real-time to fix any issues, like if the cut is off or if there are inconsistencies in the cut.

- Cooling and Debris Removal: During the cutting process, you may use assist gases like nitrogen or oxygen to cool the material and blow the molten debris out of the way of the cut, so you get a nice, clean edge.

Types of Laser Cutting Machines

CO2 Laser Cutters

CO2 lasers are among the most popular types of laser cutters used for sheet metal.

Advantages:

• Good for cutting non-metals and thicker metals.

• High-quality cuts with smooth edges.

Disadvantages:

• More expensive to maintain and operate.

• Less energy-efficient compared to fiber lasers.

Fiber Laser Cutters

Fiber lasers have become the machine of choice due to their speed and flexibility.

Advantages:

• Faster and more efficient, especially for cutting thin metals.

• Lower maintenance and longer operational life.

Disadvantages:

• More expensive to buy than CO2 lasers.

• Not as effective on thicker materials.

Comparing and Choosing

When deciding between CO2 and fiber lasers, here are some things to consider:

• Material and Thickness: Fiber lasers are better for thin metals, while CO2 lasers are better for thicker materials.

• Precision: Both machines are precise, but you may have a preference based on the tolerances you need.

• Cost: Consider the cost to buy the machine and the cost to run it.

The Best Machine for Cutting Sheet Metal

The best machine depends on what you need:

• For Home Use: The Glowforge® Pro is a great machine for small projects because it is easy to use and does a great job.

• For Industrial Use: DXTech machines are solid machines that can handle the rigors of a high-demand environment and offer a wide range of capabilities for different industrial applications.

Techniques for Cutting Sheet Metal

Fusion Cutting

Fusion cutting uses an inert gas (like nitrogen or argon) to cool the cut and blow away the molten debris. This process helps minimize oxidation and produces a clean cut.

Flame Cutting

Flame cutting, or reactive cutting, uses oxygen to speed up the cutting process through oxidation. This method is faster but can cause more thermal distortion.

Sublimation Cutting

Sublimation cutting is when the material goes directly from a solid to a vapor, skipping the liquid phase. This process is great for materials that need a precise, damage-free cut.

Materials Suitable for Laser Cutting

Laser cutting is good for many types of metals:

• Steel: Steel is popular because it is strong and can be used for many things.

• Aluminum: Aluminum is great because it is lightweight and doesn’t corrode.

• Stainless Steel: Stainless steel is used because it is hard and doesn’t rust.

• Copper: Copper is used because it conducts electricity and is easy to form.

Each metal has different properties and is good for different things. There are recommended thicknesses for cutting each metal.

Precision and Tolerances

Laser cutting is known for being very accurate:

• Tolerances: You can usually hold tolerances of ±0.005 inches.

• What Affects Accuracy: The type of material, the thickness, and the settings on the machine all play a role in how accurate you can be.

Cost Considerations

Initial Investment

When you buy a laser cutter, you have to pay for a few different things:

• The Machine: The cost of the machine varies based on the type and how fancy it is.

• Installation: You have to pay to have the machine set up in your place.

• Training: You have to make sure that your people know how to run the machine.

Operational Costs

Every month, you have to pay for:

• Electricity: Laser cutting machines use a lot of power.

• Maintenance: You have to have someone come and work on the machine to keep it running well.

• People: You have to have good people to run the machine so that you get good parts out of it.

Ways to Minimize Costs

• Keep the Machine Busy: Make sure you use the machine a lot to get the most out of it.

• Take Care of the Machine: Spend some money to keep the machine running well so you don’t have to spend a lot of money to get it fixed.

• Turn Off the Lights: Do things to cut down on how much electricity you use to keep your bill low.

Safety Measures

Protective Gear

When you’re running a laser cutter, you need to make sure you have the right safety gear:

• Safety Glasses: You have to wear safety glasses to protect your eyes from the laser light.

• Gloves and Aprons: You have to make sure you wear gloves and an apron to keep from getting cut and burned by the sharp edges and hot stuff.

Safety Rules and Regulations

Make sure you follow the rules from OSHA and other groups to keep your people safe:

• Teach Your People: Make sure they know what they are supposed to do to keep safe.

• Check Your Stuff: Make sure you look at your stuff every day to make sure it is safe.

Is Laser Cutting Dangerous?

While there are some things that can be dangerous, if you do what you are supposed to do, you can be safe:

• Don’t Burn Down the Place: Keep fire extinguishers around, and make sure you have good ventilation.

• Watch Out for the Dust: Make sure you have a good vacuum system so you don’t breathe in all the dust and fumes.

What You Need to Think About When You’re Using Laser Cutting for Sheet Metal

1.The Metal You Are Cutting

Make sure you understand the metal you are cutting:

• Metal Type: Different metals cut differently with a laser.

• Thickness: Make sure the metal you are cutting is not too thick for your machine.

2.How Complicated Your Design Is and How Fast You Want to Cut

Sometimes you have to decide between how fast you want to cut and how good you want your parts to be:

• Cutting Speed: Sometimes faster cutting is not as good.

• How Fancy Your Design Is: Sometimes you have to change your design to make it easier to cut.

3.How Much Money You Want to Spend

Look at how much money you are going to spend on laser cutting and see if it is worth it:

• Size of the Job: If you have a big job, it is easier to spend the money on a laser.

• Saving Money: Sometimes you can save money on material by using a laser and making less waste.

Conclusion

Laser cutting sheet metal is a great tool in today’s manufacturing world because it is very accurate and fast. While it costs a lot to get started and you can’t cut every material, it is a good thing to think about using for your business. If you understand both the good and the bad, you can figure out how to make laser cutting work for you.

By using a laser cutter, you can make your business better, save money, and make better parts, which will help you make more money in today’s tough world.