Your Custom Reaction Injection Molding Supplier

Low Production Run from 50—5000pcs

Allows vary wall thickness from 2mm-30mm without Sink

Enables mold parts up to 35kg in a single shot or with a part footprint of 1.8*1.2*1 meters

We carry out Painting,Silkscreen,and Production Assembly Completely "In-House"

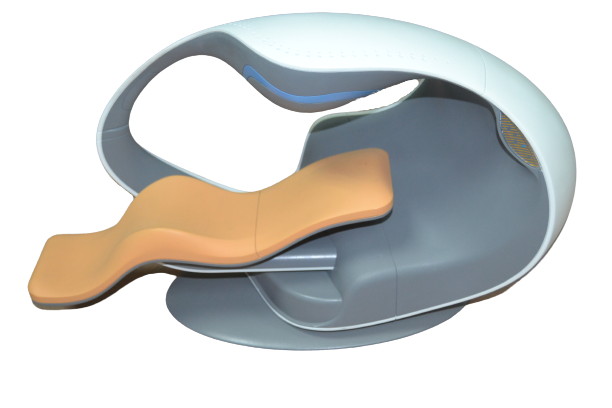

Custom Product

Gallery

What Set Us

Apart

Engineering Excellence

Secure priority access to senior engineers, bespoke DFM reviews, and tailored mold-flow strategies—your products receive exclusive innovations competitors never achieve.

Favorable Price

Cut your costs by up to 70% with aluminum molds, bulk raw sourcing, and in-house post-processing—premium RIM parts at factory-direct value.

One-Stop Solution

Simplify every stage of your project—from concept and DFMA to prototyping, finishing, painting, and logo branding—with inspection and management included.

Full Support

Get tailored RIM solutions from consultation to production and after-sales, with 24-hour quotes ensuring your project’s speed, security, and cost savings.

With You Through

Every Step

-scaled-2-1024x683.jpg)

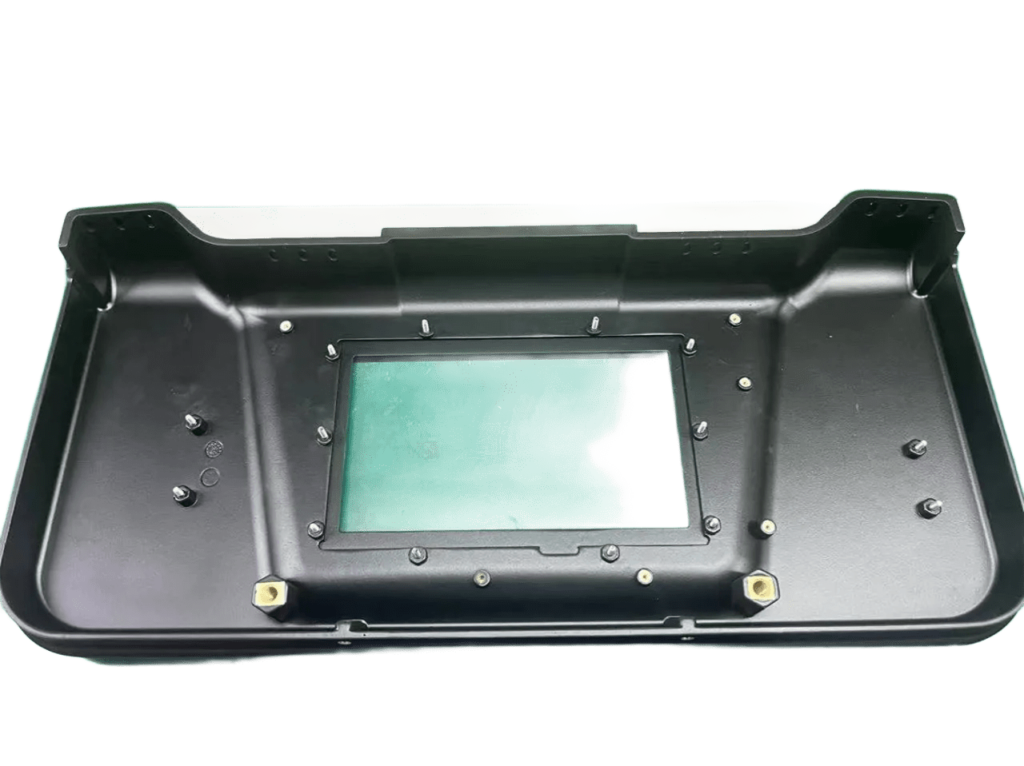

Tooling Design & Manufacturing

Kickstart your RIM project with precision tooling design. Senior engineers leverage DFMA for superior strength and functionality. Cost-effective aluminum molds deliver in 6 weeks, endure 20,000 cycles, and embed intricate features—fast-tracking your path to production.

Reaction Injection Molding

Experience precision RIM molding with our Italian machines crafting your lightweight UL94V-0, RoHS2-compliant enclosures—integrating inserts or electronics, minimizing assembly, enabling low-volume runs without setup fees, and delivering on-time with real-time updates.

Secondary Process

Elevate your RIM parts with in-house grinding, painting/texturing, screen printing, and RFI/EMI shielding—ensured by rigorous QC for impeccable adhesion, uniform finishes, robust protection, and premium enclosures that boost performance and aesthetics.

Assembly

Streamline your RIM assembly from brackets, wiring, and sensors to complete PUR system integration—with tailored instructions, procurement aid, and rigorous testing for cost-efficient, dependable, ready-to-deploy solutions that save time and boost performance.

Quality Assured

Rest assured with ISO 9001-certified in-house control over every stage—tooling, molding, inspection, and packaging. Rigorous monitoring, full traceability, and monthly reviews deliver your consistently reliable, premium parts that surpass demanding industry standards.

Shipping

Enjoy competitive rates and swift delivery via partnerships with top logistics providers. Custom, scratch-resistant, impact-proof packaging—EPE, EVA, and wooden cases—ensures your RIM products arrive pristine and on schedule, every time.

Distinct

Advantage of RIM

Discover the distinct advantages of RIM for your projects: cost-effective tooling, durable and lightweight parts, and unmatched design flexibility for complex, large-scale components—perfect when traditional injection molding falls short on volume, weight, or intricacy.

Application

Medical devices

Lab equipment

Industrial enclosures

Aerospace

Agricultural

Marine

Strong Team

Powerful Result

Partner with expert RIM specialists who optimize your designs via DFM and mold-flow analysis, delivering 12% average cost reductions, accelerated timelines, and robust PUR components—earning recommendations from 65% of clients to their industry peers.

-scaled-2-1024x683.jpg)

-scaled-1-1024x683.jpg)

Contact Premium Mold to Start Your Project

Have a look at how some of our clients perceive our parts and services: