Having trouble threading holes in your plastic and sheet metal parts? You’re not the only one. Designers struggle with tapping all the time, wasting time and money. But with the right techniques and tools, you can get perfect threads every time without any trouble. In this guide, we’ll teach you what you need to know to tap holes successfully.

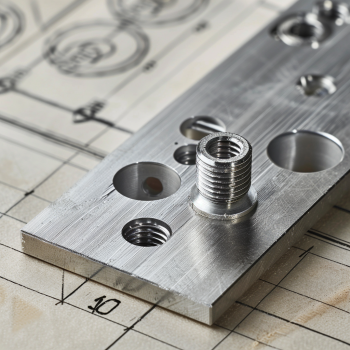

Tapping is the process of cutting threads in holes so you can put screws or bolts in them. We do a lot of tapping here at Premium, and we’ve learned a few things about how to do it right. Whether you’re working with plastic or sheet metal, you need to know about thread sizes, thread types, and how thick your material is to get good results.

Are you ready to learn more? Let’s talk about tapping holes in plastic and sheet metal, from understanding thread types and sizes to knowing where to put your holes and how big to make them. With our help, you can make great threaded parts that will work for your project.

What is Tapping and Why is it Important?

Tapping is the process of creating threads in pre-drilled holes so you can put screws, bolts, or other fasteners in them. This is important because you have to be able to put stuff together and make sure it stays together when it’s under stress. You can tap a hole by hand or use a machine to do it for you, depending on what you’re doing and how precise you need to be.

Importance of Tapping in Manufacturing

Tapping is important in manufacturing for a few reasons:

- Strength and Durability: When you tap a hole, it makes sure your bolts and screws stay in and hold your stuff together. This makes your parts strong and durable so they can handle whatever you’re doing.

- Precision: Tapping helps you line up your parts exactly right, which is important in industries like aerospace and automotive where everything has to be perfect.

- Cost-Efficiency: Using a machine to tap holes is faster and cheaper than doing it by hand. This makes manufacturing more efficient because you can get more stuff done faster.

- Versatility: You can tap holes in lots of different materials, like metal and plastic. This makes tapping a good way to put stuff together no matter what you’re working on.

- Quality Control: If you tap a hole right, your screws and bolts won’t come out. This makes sure your parts work right and are safe and reliable for whatever you’re doing.

Advanced Tapping Techniques

Using Threaded Inserts for Extra Strength

Threaded inserts like Helicoil or keenserts can be used to make threads stronger in softer materials like plastic and softer metals. These inserts make your threads more durable and wear resistant.

• Helicoil Inserts: These are wire coils that make threads stronger in soft materials.

• Keenserts: These are solid threaded inserts that make really strong, permanent threads.

Tapping Blind Holes

Tapping blind holes (holes that don’t go all the way through the material) can be tricky because you don’t want to go through the bottom and wreck your part.

• Blind Hole Taps: Use taps made just for blind holes. They have a shorter start and cut more at the tip.

• Depth Control: Make sure you know how deep the hole is and how far the tap goes in so you don’t bottom out and wreck your threads.

Coolant and Lubrication

The right coolant and lubrication can make your taps last longer and make your threads better.

• Coolants: Use coolants that work with the material you’re tapping. They help remove heat and keep your tap from breaking.

• Lubricants: Put the right lubricant on your tap, like tapping oil. It helps reduce friction and makes your threads look better.

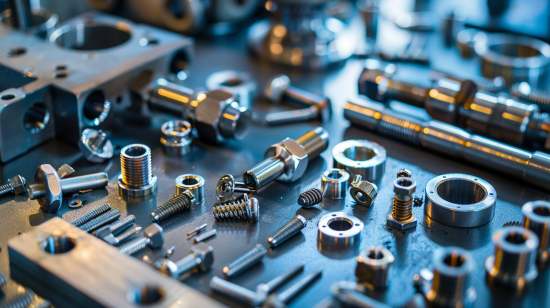

Understanding Thread Types and Sizes for Fasteners

Thread Engagement(How Much of the Screw Goes Into the Hole?)

Thread engagement is how much of the screw goes into the hole. This is important for strength, especially if you’re pulling something apart. Make sure your screws go in deep enough based on how strong your material is so your stuff works right.

Thread Pitch

Thread pitch is how close together the threads are. This is measured differently depending on where you are:

• SAE (Society of Automotive Engineers): Uses inches. For example, 1/2-20 means a 1/2-inch screw with 20 threads per inch.

• Metric: Uses millimeters. For example, M10-1.5 means a 10mm screw with 1.5mm between threads.

• ANSI (American National Standards Institute): Has its own sizes. For example, 10-32.

Diameter

The diameter is how big the hole and screw are. Make sure you get the right size so your screw and hole match up and you can screw things together nice and tight.

Choosing the Right Thread Type

When you’re picking a screw, you need to think about:

- What Material You’re Using: Different materials need different screws to make sure they stay together and stay strong. For example, plastic might need big threads, while metal might need small threads.

- What You’re Doing: Think about where your stuff will be and what it has to do. Big threads are good if you have to take stuff apart a lot, while small threads are good if your stuff has to be really strong and work right.

- What People Expect: Depending on where you are, you might have to use SAE, Metric, or ANSI screws. Make sure you get the right screws for your stuff.

Coarse Thread vs. Fine Thread: Which is Better?

Deciding whether to use big threads or little threads depends on what you need. Here’s a quick comparison:

- Coarse Threads: Farther apart, fewer threads in a screw or hole. Usually used for normal stuff. They’re easier to screw together and don’t get messed up as much when you handle them.

- Fine Threads: Closer together, more threads in a screw or hole. Used for stuff that needs to be strong and needs to be adjusted carefully.

Pros of Fine Threads:

• Stronger for the same size compared to coarse threads

• Make it easy to adjust stuff

• Don’t come loose as much

Cons of Fine Threads:

- More likely to get stuck and messed up

- Less suitable for high-speed assembly

- Need to go in deeper

Tap Size and Placement Considerations

What Size Hole Do I Need?

We make the holes the right size for the screws so they fit right. But you need to look at our chart to make sure the holes are the right size based on where the closest cut is.

Where Do I Put the Hole?

The middle of a hole you tap needs to e at least half the size of the screw plus the smallest distance from the edge to the hole based on the closest cut. This makes sure the part works right and doesn’t break..

Thread/Tap Hole Size Chart

Here’s a quick reference for standard tap sizes and their corresponding hole sizes:

| Tap Size | Hole Size (mm) |

| 4-40 | 2.32 |

| 6-32 | 3.00 |

| 8-32 | 3.51 |

| 10-32 | 4.17 |

| 1/4-20 | 5.31 |

| 1/4-28 | 5.62 |

| 5/16-18 | 6.76 |

| 5/16-24 | 7.07 |

| 3/8-16 | 8.21 |

| 3/8-24 | 8.67 |

| 1/2-13 | 11.05 |

| 1/2-20 | 11.66 |

| M2 x 0.4 | 1.66 |

| M2.5 x 0.45 | 2.11 |

| M3 x 0.5 | 2.60 |

| M4 x 0.7 | 3.41 |

| M5 x 0.8 | 4.32 |

| M6 x 1.0 | 5.16 |

| M8 x 1.25 | 6.96 |

| M10 x 1.5 | 8.74 |

Choosing the Correct Tap for Your Material Thickness

For the best strength, you should aim for a thread depth of 1 to 1.5 times the size of the bolt. For example, an 8-32 bolt should have a thread depth in the material of about 0.138” to 0.208”. This makes sure your threads are strong enough to hold the stuff you’re putting together.

Materials Available for Tapping

We support tapping on a variety of materials, each with specific thickness ranges:

- Aluminum: 1.6mm-12.7mm (5052/6061/7075)

- Copper: 1.6mm-6.35mm

- Brass: 1.6mm-6.35mm

- Stainless Steel: 1.5mm-12.7mm (304), 1.5mm-6.35mm (316)

- Mild Steel: 1.5mm-12.7mm

- Plastics:

- 3mm-5.6mm (Polycarbonate)

- 3.2mm-6.35mm (Delrin)

- 6.35mm-12.7mm (HDPE)

- 3.2mm-6.35mm (ABS)

Specialized Tapping Considerations

Tapping Thin Material

When you’re tapping thin stuff, you don’t want to strip your threads and you want to make sure you have enough of them.

• Thread Rolling: Instead of cutting the threads, you can roll them if you’re tapping thin stuff. This makes the threads stronger without taking away any material.

• Backing Support: Put something behind your thin stuff when you tap it so you don’t mess it up and so you can make sure your threads are right.

Tapping Stuff That’s Made of a Bunch of Stuff

If you’re tapping stuff that’s made of a bunch of stuff, like carbon fiber or fiberglass, you have to be careful.

• Use Special Taps: Use taps that are made for stuff made of a bunch of stuff. They have different shapes to make sure you don’t mess up the stuff that’s made of a bunch of stuff.

• Drill and Tap at the Same Time: Use tools that drill and tap at the same time. This way you don’t have to move stuff around, and you can make sure your screws go in straight.

Don’t Let Your Plastic Get Too Hot

When you tap plastic, you don’t want it to get too hot because it will melt and get messed up.

• Low-Speed Tapping: Tap your plastic slowly so it doesn’t get too hot.

• Cooling Methods: Use air or water to keep your plastic from getting too hot and make sure your threads come out right.

Quick File Setup & Design Points

• Make your holes the right size using our chart.

• Make sure your tapped holes are at least half the size of the tap away from where you bend the part to keep it from getting messed up.

• We can only tap holes that go straight into the part.

• Your part needs to be:

o At least 1” x 1.5”

o No bigger than 36” x 46”

What to Expect on Finished Parts

• Your parts might have a little oil on them.

• You might need to clean up some edges.

• Holes near where you bent the part might be messed up and you might need to fix them.

• All the holes we tap will turn to the right.

• It might take us a couple of days to tap your parts.

Plastic and Sheet Metal Tapping Services

Service Overview

Tapping is when we make holes that have threads in them so you can put screws in them. Our tapping services let you skip the hard part and get right to using your part. We use special machines to make a hole, put threads in it, and send you on your way. Our team of skilled workers (and robots) only focus on tapping.

Quality Control

Whether we’re tapping one part or a bunch of them, we look at every single part to make sure it’s right. If we see something wrong, we’ll call you to fix it before we make the thread.

Materials Supported

Premium tapping services can be applied to a variety of materials in several thickness levels, including:

- Aluminum

- Copper

- Brass

- Stainless Steel

- Mild Steel

- Chromoly

- Delrin

- HDPE

- Polycarbonate

- ABS

Conclusion

We hope this helps you make your parts work better with us. If you do what we say, you’ll get the right tapped holes every time. Look at our other pages for more details and if you have questions, ask. We have nice people who know a lot and they’ll get back to you right away!