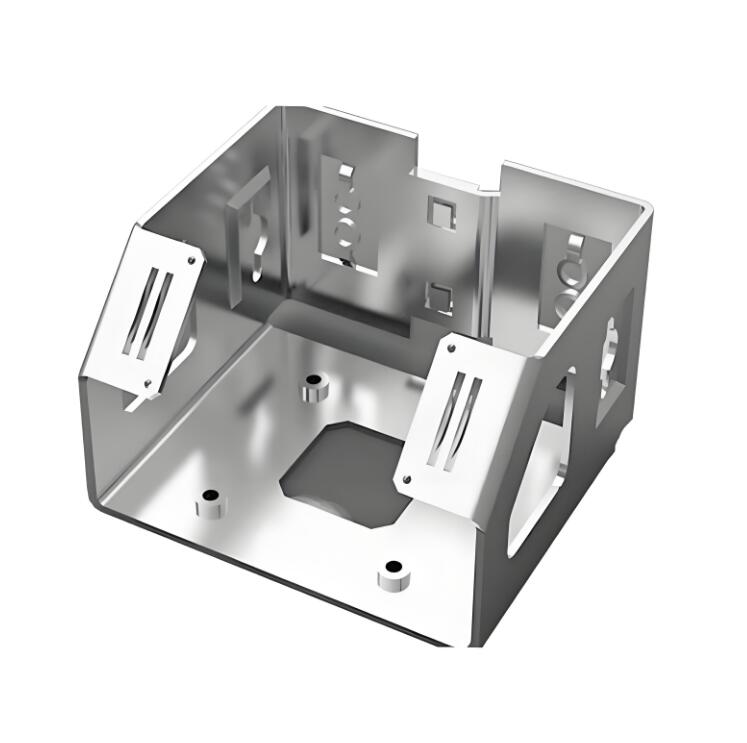

Sheet metal fabrication can be complicated, especially when it comes to making sure the parts line up when you go to put them together. One way to make this simpler is to use slots and tabs. At Premium Rapid & Mold, we see customers who are struggling with welding, which is slow and tedious, and have issues lining parts up. Adding slots and tabs to your design can make a big difference in the quality and efficiency of your sheet metal designs. But how does it work and what are the benefits?

When you add slots and tabs to your sheet metal designs, the parts line up perfectly during welding and assembly. This makes the process faster and more accurate, which leads to better quality and less time making the parts.

As someone who has spent a lot of time in metal fabrication, I can tell you it can be a real pain to line up parts manually. Slots and tabs act as self-fixturing elements, so you don’t have to use clamps or jigs. This speeds up the process and guarantees the parts are aligned perfectly, so you are less likely to make a mistake and have to do it over. Let’s talk about how slots and tabs work and the advantages of using them in your sheet metal designs.

Why Should You Use Slots and Tabs in Sheet Metal Fabrication?

Slots and tabs are great for sheet metal fabrication. They help you put parts together by acting like built-in fixtures that align your parts accurately. This is especially useful when you’re putting together a complex assembly where you need to be precise. For example, if you’re making a box structure, you can put tabs in corresponding slots to hold your parts in place for welding. This method of self-fixturing saves you time on setup and helps you make sure everything is the same every time.

When you add slots and tabs to your designs, you can cut your assembly time by up to 30%. According to the Journal of Manufacturing Processes, this method makes a big difference in how well your parts line up and the overall quality of your product.

Another great thing about slots and tabs is that they save you money. By reducing the need for extra fixtures and cutting down on assembly time, you can lower your costs. In addition, slots and tabs make your assembly stronger. If you design your tabs correctly, they help distribute the load evenly and prevent your parts from bending. This makes your final product stronger.

Key Design Principles for Slots and Tabs

When you’re designing your parts for slots and tabs, you need to follow some rules to make sure they work and are easy to put together.

Dimensions and Tolerances

• Tabs: You need to make your tabs at least twice the thickness of your material or 0.125 inches wide, whichever is bigger. This way they’re strong enough to hold the load without bending.

• Slots: Your slots need to be a little bigger than your tabs so your tabs fit in easily. At Premium, we tell people to make their tabs 0.00025 inches smaller than their slots all the way around. This way, your parts fit together tightly, but you don’t have to force them and mess them up.

Aluminum Considerations

• Aluminum Parts: If you’re working with aluminum parts, you need to make your slots a little bigger because you have to fill them with weld since you can’t melt aluminum like you can steel or stainless. This keeps you from screwing up your parts when you weld and makes a stronger joint.

Quantity and Placement

• Less is More: Usually, when it comes to the number of tabs and slots, you should follow the “less is more” rule. For instance, three tabs on a 0.315-inch flange is plenty, but seven is too many. This makes your design simpler and avoids having too many places where things can go wrong.

• Strategic Placement: Put your slots and tabs where they will help you the most with alignment and strength of your part. For example, you want to put them on corners and at points where your part will carry the most load.

Design for Manufacturing (DFM)

• Ease of Assembly: Make your slots and tabs to make it easier to put your parts together. This means thinking about the order you put things together and making sure you can line your parts up and hold them together without needing extra tools.

• Material Thickness: Make sure your material thickness is consistent and works with your tabs and slots. If your thickness varies, your parts won’t fit together right and they won’t be as strong.

Best Practices for Designing Slots and Tabs

When you’re designing your parts for slots and tabs, there are some things you should do to make sure they work right and are easy to use.

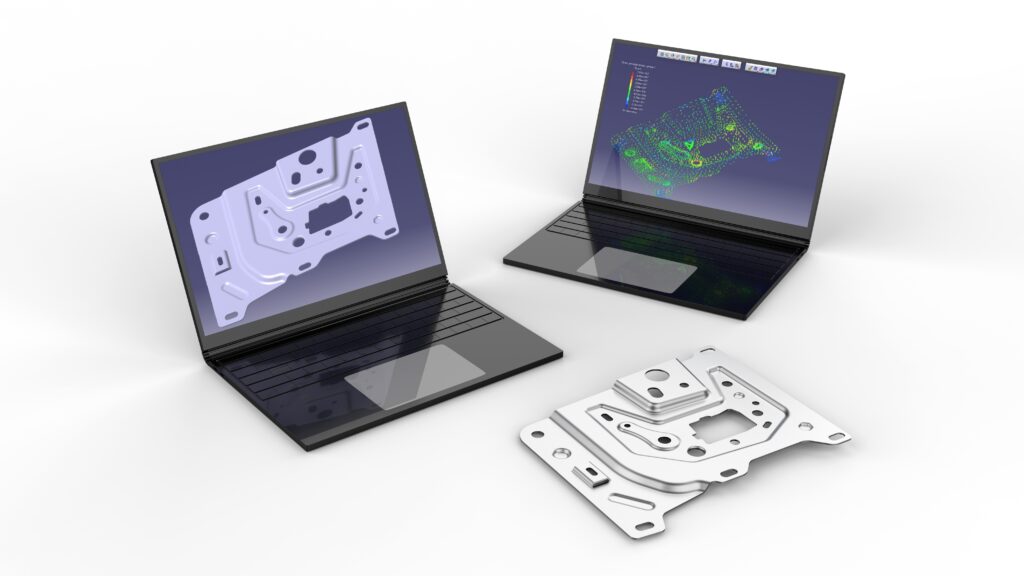

Use SOLIDWORKS for Design

If you’re designing in SOLIDWORKS, use the Tab and Slot feature in the Sheet Metal toolbar. This tool makes it easy to design slots and tabs and lets you tell SOLIDWORKS how many you want and how to space them. SOLIDWORKS walks you through the process of putting these features in your 3D model, so they’re accurate and consistent.

Avoid Narrow Slots Near Bends

Slots can cause problems when they get close to a bend. Make sure your slots are at least four times the thickness of your material away from the bend so you don’t mess up the bend. If you have to, cut the slot through the bend so you don’t have these issues.

Ensure Slot Width is Adequate

Narrow slots, especially those less than the thickness of your material, can cause problems with the cut quality. Make sure your slot is at least as wide as the thickness of your material so your part is accurate and good quality.

Consider Powder Coating and Other Surface Treatments

If you’re going to powder coat or do other things to your parts, you need to adjust your slot size. Powder coating adds between 0.002 inches and 0.005 inches per side. If your tab is 1 inch wide, it should be 1.002 to 1.005 inches wide if you’re going to powder coat. This way, your parts fit together right after you treat them.

Optimize for Assembly

Designing your parts so they’re easy to put together can save you a lot of time and keep you from making mistakes. Put your tabs and slots in a place that makes putting your parts together easy and straightforward. To keep from messing up, design your tabs so they only fit into their slots one way.

Prototype and Test

Before you finish your design, make some parts to see if your tabs and slots work right. This way, you can find out if you have any problems that you didn’t see when you were designing your parts digitally. Once you know how your parts work in the real world, you can make changes to make sure your final product does what it’s supposed to.

Plan for Manufacturing Variations

Your parts may be a little different when they come out of manufacturing. Design your tabs and slots so they work even if your parts are a tiny bit different, so you know they’ll fit together right even if they aren’t exactly the same every time.

How Does Premium Approach Slot-and-Tab Design?

At Premium, we put slots and tabs in our weldment parts all the time. This is something that sets us apart from a lot of other metal fabrication shops. It helps us line things up perfectly and weld better. It also helps us put parts together.

For example, we create 0.25 mm long tabs that are 0.007 mm smaller than their coordinating slots on all sides. This way, the tab goes in the slot super easy, and it helps you put your parts together.

When we put slots and tabs in our parts, we don’t have to spend a lot of time making fixtures, which saves us time setting up and helps us make things faster. This not only helps us weld better, but it also makes our parts stronger.

How Do Slots and Tabs Benefit Different Applications?

Slots and tabs can be used in a lot of different things, from machinery to stuff you buy. Here are a few examples:

Industrial Uses

In machinery, slots and tabs help you put things together better. They help you line things up and make them faster, which is really useful when you’re working on something that you need to be perfect.

Consumer Products

In electronics, slots and tabs help you make things look good and work better. They let you make clean designs without seeing all the screws, which makes your stuff look better.

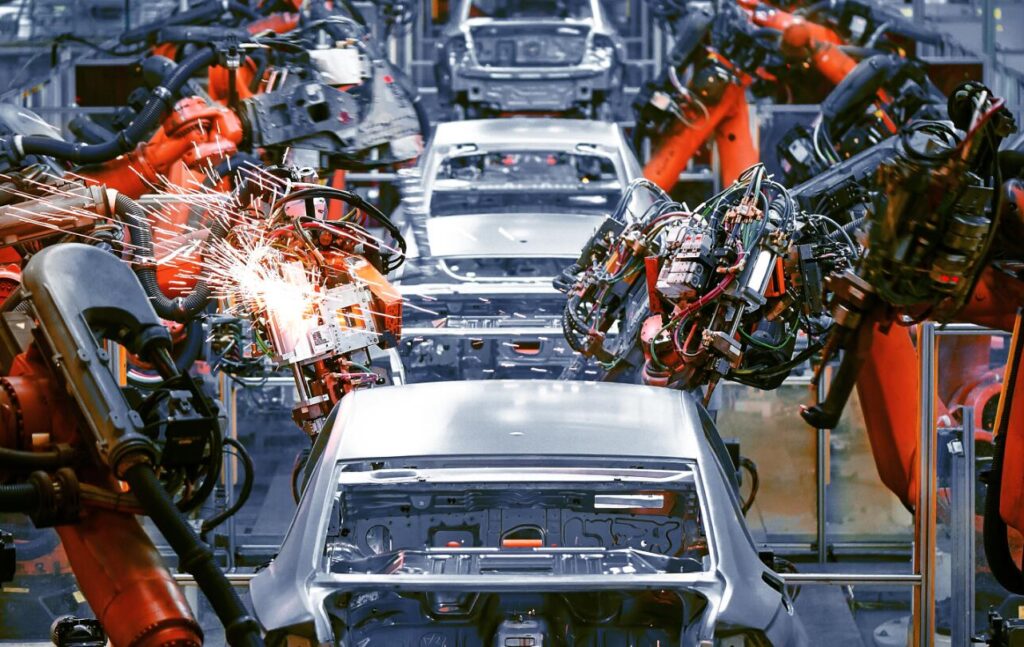

Automotive Sector

In car parts, slots and tabs help you make strong parts that don’t weigh much. They help you make strong joints and keep the weight down, which makes your car go faster.

Small-Scale Assemblies

In your own stuff, you can use slots and tabs in things like cell phone holders. They help you put things together and make your stuff work better. Slots and tabs make your stuff easy to use and let you customize things, which is cool.

What Are the Challenges and Solutions in Slot-and-Tab Design?

While slots and tabs are great, there are some things to think about. Here’s how to fix some of the problems you might have:

Misalignment Issues

Make sure you cut and bend your parts right or they won’t line up. Use good CAD software and check your parts to make sure they’re the same.

Material Deformation

Pick the right sheet metal so your parts don’t bend. If you use thicker material, it can make your design harder, so make sure you think about what kind of metal you’re using.

Assembly Tolerances

Make sure your parts fit together right by checking your parts. Make sure your parts fit together right by looking at them and making sure they fit together right.

Design Complexity

Make your design easy to make and easy to put together. This will make it cheaper to make and make your parts better.

Bent Parts

If you use tabs and slots between two sides of the same part, make sure you think about the bend. Make sure you design your part so the bend fits right and your parts don’t run into each other.

Space Constraints

Cut out parts near screws, nuts, or electronics and make sure your parts are still strong. This way, your part works right and is strong.

Bent Tabs and Spot Welding

Use bent tabs with spot welding or rivets to put your parts together without making your parts longer or welding the edges of your parts. This way, your parts are strong, and you don’t have to do a lot of welding.

Real Data on Slot-and-Tab Design

Research shows that when you use slots and tabs in your sheet metal designs, you can make your parts faster and better.

According to the Journal of Manufacturing Processes, using slots and tabs can cut your assembly time by up to 30%. This method makes sure your parts line up better and are the same every time.

Another study by the Sheet Metal and Air Conditioning Contractors’ National Association (SMACNA) found that slots and tabs can make your joints 25% stronger than traditional welding. This research shows why you should use slots and tabs in your sheet metal parts.

Key Takeaways

• Notches and Tabs: Give you a place for your tools and help you put your parts together.

• Notches: Should be at least 0.040 inches or the thickness of your material (whichever is bigger) and should be no deeper than four times their width.

• Tabs: Need to be at least twice the thickness of your material or 0.125 inches wide (whichever is bigger) and no more than four times their width for them to be strong.

• Slots: Make your part look good and help with airflow and design.

• Self-Fixturing: Slots and tabs help you line your parts up and make them faster.

• Cost: When you don’t need a lot of fixtures and you can put your parts together faster, you make your parts cheaper.

• Materials: Different materials need different slot sizes. For example, aluminum needs bigger slots because you have to fill them with weld.

• Software: Use CAD software like SOLIDWORKS to design your slots and tabs. This way, they’re right, and you can put them in your 3D models.

• Prototypes: Make parts to see if your tabs and slots work. This way, you can find and fix problems early.

Using SOLIDWORKS for Designing Slots and Tabs

Tab and Slot Feature

Use the Tab and Slot feature in the Sheet Metal toolbar in the CAD software or go to Insert > Sheet Metal > Tab and Slot. This feature makes it easy to design slots and tabs and makes sure they’re accurate.

Design Process

The software tells you how many slots and tabs to put in your part and how to space them before you put them in your 3D model. This way, your parts are accurate and the same every time.

Premium Goes Above and Beyond

Expertise

We put slots and tabs in our weldment parts to make sure they line up perfectly and weld better. This helps us make parts faster and stronger.

Customer Support

We help you put slots and tabs in your CAD models to make your parts better and faster. Even if you don’t buy parts from us, we’ll help you.

Metal Fabrication Slots and Tabs FAQ

What are slots and tabs when you make sheet metal parts?

Slots and tabs are things you add to your parts to make them better. They help you line your parts up and make them faster. They also help you put your parts together.

How do slots and tabs help you put your parts together better when you weld them?

When you put slots and tabs in your sheet metal parts, you don’t have to use clamps or measure things to line your parts up when you weld. They make your parts go together fast, and you can weld better, making your parts faster and better.

Do you have to use slots and tabs in your parts when you make them at Premium?

You don’t have to put slots and tabs in your parts when you design them. But if you do, your parts will weld better and go together faster. If you don’t know how to put slots and tabs in your parts, we can help you.

How do you make slots and tabs in your sheet metal parts?

You need to put a 0.010-inch long tab in your parts that is 0.00025 inches smaller than the slot on all sides. This way, your parts go together fast.

Can you use SOLIDWORKS to make slots and tabs in your parts?

Yes. SOLIDWORKS has a special tool for making slots and tabs in your sheet metal parts. This tool makes it easy to put these features in your 3D models and helps you figure out how many slots and tabs to put in your parts.

Conclusion

When you add slots and tabs to your sheet metal designs, you get a lot of benefits. You get better assembly accuracy, and you get lower production costs. If you follow some best practices and work with Premium, you’re going to get a better quality part that’s easier to make. Whether you’re working on industrial machinery, consumer electronics, or automotive parts, slots and tabs are a great way to accurately and efficiently put things together.

When you add these things to your designs, not only do you make it easier to make the part, you also make a better part. If you want to know more about how slots and tabs can help you, let me know. We’d be happy to help you get the most out of our custom sheet metal services.