Are you struggling to figure out the best way to make automotive parts? You’re not alone. Many automotive manufacturers have a hard time balancing cost, quality, and how fast they can make something. Sheet metal fabrication is a great way to do this. Here’s why it’s so great and how it can help you make automotive parts.

Sheet metal fabrication is a great way to make stuff. It’s cheap, it’s precise, it’s flexible, and it’s durable. You can make lightweight, complicated parts that are really accurate and that work. You can make stuff out of lots of different metals and finishes, which is great for the automotive industry.

It’s important to pick the right way to make stuff when you’re making automotive parts. Sheet metal fabrication is great because it’s flexible, you can make stuff out of lots of different materials, it’s accurate, and it’s cheap. With great technology like CAD and CNC systems, you can make great parts that meet the strict demands of the automotive industry. Understanding the benefits of sheet metal fabrication will help you make the right decision and make your stuff better.

What Are the Key Benefits of Sheet Metal Fabrication in the Automotive Industry?

Design Flexibility

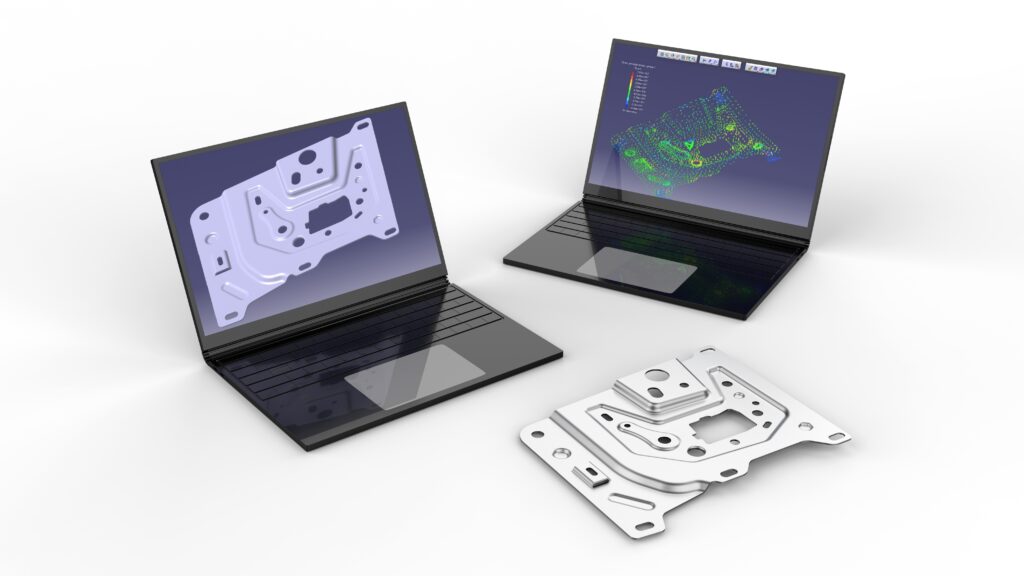

Sheet metal fabrication allows you to make parts with complex, intricate shapes. The automotive industry needs parts that are more complicated all the time. Using CAD in sheet metal fabrication has made the manufacturing process more accurate. That means the parts fit perfectly and line up when you put them together. This flexibility is important to create new designs and make what your customers want.

Material Versatility

With sheet metal fabrication, you can make stuff out of lots of different metals and their alloys. That means you can choose the best metal based on how it works, how much it costs, and what you’re using it for. In the automotive world, you can make stuff out of aluminum, stainless steel, cold-rolled steel, galvanized steel, titanium, copper, and magnesium. Each metal has a different benefit, like it’s lightweight, it doesn’t rust, or it’s really strong. That makes them good for different parts in cars.

Precision and Accuracy

When you make stuff with sheet metal fabrication for the automotive industry, it’s really accurate. The processes like laser cutting, plasma cutting, bending, and welding allow you to make parts that are really, really close to what you want. When you use CNC systems, it makes it even more accurate and precise. That means you can make a part over and over and over again and it will be the same every time. This is important to make sure your car parts are good quality.

Lightweight Parts

When you make parts with lightweight materials like aluminum or high-strength steel with sheet metal fabrication, you make the parts lighter. When you have lighter parts, the car uses less gas, makes less pollution, and goes faster. You can make thin, lightweight car parts that are still strong enough to work. Sheet metal fabrication is great for making the new cars people want to drive.

Cost-Effective Production

Sheet metal fabrication is really good at making parts for the automotive industry at low costs. You can make a lot of high-quality parts at once and it doesn’t cost a lot of money. The machines are really good at making the parts the same every time, so you don’t waste any. Metal is easy to find and not very expensive, which is good for people who make cars. This saves money on making car parts and makes it easy to fix or replace them.

What Metals Are Commonly Used in Automotive Sheet Metal Fabrication?

Aluminum

Aluminum is lightweight and doesn’t rust, so it’s perfect for the automotive industry. You can make parts out of aluminum that are lightweight and strong. People use it to make hoods, doors, and fenders. People use aluminum in cars because it makes them use less gas and it doesn’t pollute as much.

Stainless Steel

Stainless steel is a tough metal that doesn’t rust and looks good. People use it to make things like exhaust pipes, body panels, and seat frames. Stainless steel is what people use when they need a part to last a long time and work really hard.

Cold Rolled Steel

Cold-rolled steel is a strong metal that has a nice finish and is really accurate in size. People use cold-rolled steel to make things like doors, frame rails, brackets, and seat frames. People use cold-rolled steel when they need a part to be really strong and work right.

Galvanized Sheet

Galvanized steel is steel coated with zinc to keep it from rusting. People use it to make parts that are outside in the weather, like car frames and body panels. Galvanized steel is good because it makes the parts last a long time and not break.

Titanium

Titanium is really strong and doesn’t rust, so people use it to make parts that are really heavy. People use titanium in parts that are really hot because it doesn’t melt. Titanium is expensive, so people only use it in really expensive car parts.

Copper

Copper is a metal that is really good at carrying electricity, so people use it to make parts like wires and things to cool off your car. Copper is good at making parts that need to get hot and cold really fast.

Magnesium

Magnesium is a metal that is lightweight and strong, so people use it to make parts that are really light and strong. People use magnesium instead of aluminum in parts like steering wheels, dashboards, and transmission cases. Magnesium is good at making parts that need to get rid of heat really fast.

What Are the Key Techniques in Automotive Sheet Metal Fabrication?

Cutting Techniques

Sheet metal cutting techniques are used to make small parts that are the right size. Common cutting techniques include laser cutting, plasma cutting, and shearing.

Laser Cutting

Laser cutting uses a laser to melt or vaporize the sheet metal, making a clean cut. It’s really precise and good for making complicated stuff. When you use a CNC system, it’s even more precise. People use it to make parts like body panels and engine stuff.

Plasma Cutting

Plasma cutting uses really fast gas to melt the metal and blow it away. It’s good for cutting really thick metal sheets and making stuff like car frames.

Shearing

Shearing uses a shearer to push down on the sheet metal and cut it into the right shape. It’s not as precise as laser cutting or plasma cutting, but it’s good for parts like brackets and supports that don’t have to be perfect.

Forming Techniques

Forming techniques are used to make the sheet metal into the right shape. Common forming techniques include bending and stamping.

Bending

Bending uses a press brake machine to make the sheet metal bend into angles and curves. It’s good for making parts like brackets, frames, and doors. The press brake machine pushes down on the metal in the right spots to make it bend.

Stamping

Stamping uses a die to push the sheet metal into the right shape. It’s good for making a lot of parts like body panels and brackets. Stamping includes blanking, punching, and embossing.

Joining Techniques

Joining techniques are used to put together a bunch of sheet metal parts. Common joining techniques include welding and riveting.

Welding

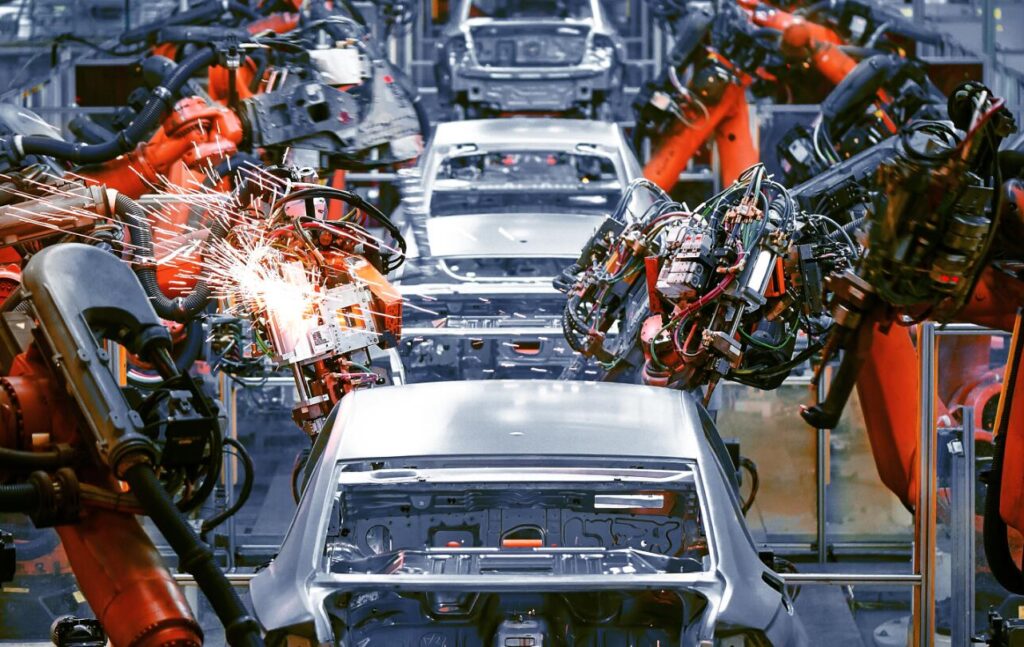

Welding uses heat to put two or more pieces of sheet metal together. Common welding techniques include spot welding, MIG welding, and TIG welding. Welding makes strong, tough joints, so people use it to make parts like car frames and body panels.

Riveting

Riveting uses a hole in the sheet metal parts to line them up, put a rivet in, and squish it to keep them together. It’s good for putting together parts made out of different metals and making really strong joints. People use riveting for parts that need to be tough and last a long time.

How Are Sheet Metal Fabrication Parts Used in the Automotive Industry?

Car Bodies and Frames

Sheet metal fabrication is used to make car bodies and frames. These parts need to be really strong and made very accurately. People use high-strength steel and aluminum to make sure these parts are strong and last a long time.

Car Customization

Sheet metal fabrication is used to make car parts that are custom. People use welding or riveting to make custom body kits, exhausts, grille guards, fender flares, and the frame of the car. This is good because people can make their car look the way they want and add stuff to it.

Vintage Car Restoration

Sheet metal fabrication is used to fix up old cars. People use these techniques to fix broken parts or replace parts that are too old. This makes the car work better and look better. People who like old cars can make them look like new using sheet metal fabrication.

Heat Shields

Heat shields are used to keep parts of the car from getting too hot from the engine and exhaust. These shields are made of aluminum or stainless steel because they’re really good at staying cool and not catching on fire.

Fuel Tanks

Sheet metal fabrication is used to make fuel tanks for the car. These tanks need to be strong and not leak. The tanks are made of steel or aluminum to make sure they are strong but not too heavy.

Brake Components

Brake parts like calipers and backing plates are made out of sheet metal. These parts need to get really hot and not break, so people use high-strength steel to make them.

Suspension Parts

People use sheet metal fabrication to make suspension parts like control arms, brackets, and subframes. These parts need to be really strong and last a long time because they hold up the car and keep it from falling apart.

Battery Enclosures

With more electric cars being made, battery enclosures are really important. These enclosures keep the batteries safe from the weather and things that might hit them. People use aluminum to make these enclosures because it’s lightweight and doesn’t rust.

Transmission Covers

Transmission covers protect the transmission from dirt, rocks, and stuff that might hit it. These covers are made of aluminum or steel so they don’t break and can handle the heat.

Exhaust Systems

Exhaust parts like manifolds, pipes, and mufflers are made using sheet metal fabrication. People use stainless steel for these parts because it can get really hot and not rust.

Engine Mounts

Engine mounts hold the engine to the frame of the car. These mounts are made of sheet metal so they are strong and keep the engine in place. People use high-strength steel to make them.

Door Handles and Latches

Door handles and latches help you get in and out of the car. These parts are made of stainless steel or aluminum so they don’t break and look good.

Airbags and Safety Restraints

Sheet metal fabrication is used to make parts for airbags and other safety stuff. These parts make sure the airbags go off right and keep you safe in a crash.

Case Studies: Successful Implementations of Sheet Metal Fabrication in Automotive

Tesla Model S

Tesla used sheet metal fabrication to make the aluminum body of the Model S. The car is really fast and can go really far, showing that aluminum is good for making cars.

Ford F-150

Ford uses aluminum to make the body of the F-150 truck. This makes the truck weigh less and use less gas. The truck is still strong enough to work and last a long time.

BMW i3

The BMW i3 electric car has a body made from aluminum and plastic. Sheet metal fabrication helped make the car look cool and work really well.

What Are the Challenges and Tips for Choosing Automotive Sheet Metal Fabrication?

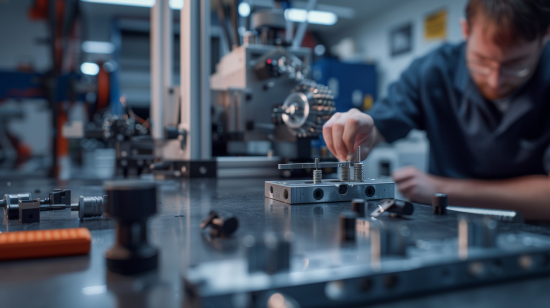

Keep It Precise

It’s hard to keep stuff right when you make it. If things aren’t right, it’s hard to put them together. To make things right, follow the rules and use computers to help you with stuff like welding, cutting, and bending.

Ensuring Quality Materials

It’s important to use good stuff when you make stuff with sheet metal fabrication. If you don’t, your parts will break and not work right. Make sure you get your stuff from good companies that sell the best stuff.

Manufacturing Tolerances

Some parts need to fit really tight. This can make it hard to make stuff. If you can’t do it, find a company that can. It’s better to pay someone else than to spend a lot of money on machines that you might not use all the time.

Get Great Automotive Sheet Metal Fabrication from Premium

Premium is an automotive sheet metal fabrication company in the United States. We make parts for car companies around the country. We work with people who make car parts and people who buy car parts to make the parts they need right and fast. Our team of sheet metal workers, laser operators, and programmers know that it doesn’t matter how fast or how much something costs if it doesn’t work. Big companies trust us to make their stuff. Come see why they like us for their sheet metal parts.

Why Choose Us?

Making good metal parts is important when you make stuff for cars. Car parts have to work in really cold and really hot weather and fit just right. At Premium, we know how to make parts for cars. We make stuff out of different metals like stainless steel, aluminum, and brass. We can make the metal shiny or paint it. We also have a laser to cut the parts and make sure they are perfect. If you need a few parts or a lot of parts, we can help. Call us today and we’ll help you make parts for cars.

Conclusion

Making stuff for cars is easy if you know how to use sheet metal fabrication. If you use the right metal and the right technique, you can make anything you want. At Premium, we make great parts for cars. We know how to use sheet metal fabrication to make parts that work great and last a long time.

FAQs

How thick is the metal used in cars?

The metal you use in cars is usually 18-22 gauge. The most common thickness is 20 gauge. The lower the number, the thicker the metal.

What metal is used in cars?

Most people use aluminum and stainless steel in cars. They are really strong and last a long time. They also have cool things about them that make them good for cars.

How can I save money on metal parts?

Make sure you design the parts right, pick the right metal, and work with your sheet metal guy to save money and make the parts good.

What can I use to make my metal parts right?

You need to use good computers and lasers to make sure the parts are right. You need to make sure the parts are right all the time.

How do I make sure the parts are the same every time?

Make sure you check the parts and use math to make sure they are the same every time. You also need to make sure the parts are right before you make a lot of them.

How do I talk to the person who makes my parts?

Make sure you talk to the person and write down what you want. Make sure you and the person making your parts understand what you want.