HVAC sheet metal fabrication is the process of making the sheet metal components that are essential for HVAC systems, including ductwork, vents, air-handling units, and more. The goal is to make the HVAC system efficient, long-lasting, and custom to the specifications of the building, which will make the building safer, more energy-efficient, and help distribute the air properly.

HVAC sheet metal fabrication involves several steps: selecting the right material (such as aluminum, galvanized steel, stainless steel, etc.), designing the sheet metal using CAD software, cutting and forming the sheet metal using methods like laser cutting and bending, and finally, assembling the sheet metal components using methods like welding and riveting. The sheet metal components have to be finished properly with surface treatment and sealing to make sure they last and look good. It’s also important to maintain the components by changing filters and cleaning coils to keep the HVAC system running efficiently.

Understanding HVAC sheet metal fabrication is important for those involved in building maintenance, construction, or HVAC system design. It’s the process that turns raw material into the components that make our indoor environments comfortable. From selecting material and gauges to the industrial processes of cutting, forming, and assembly, each step requires skill and knowledge. In this post, we’ll examine each step and give you a comprehensive understanding of how the HVAC systems you see every day are created through sheet metal fabrication.

What Are the Steps Involved in HVAC Sheet Metal Fabrication?

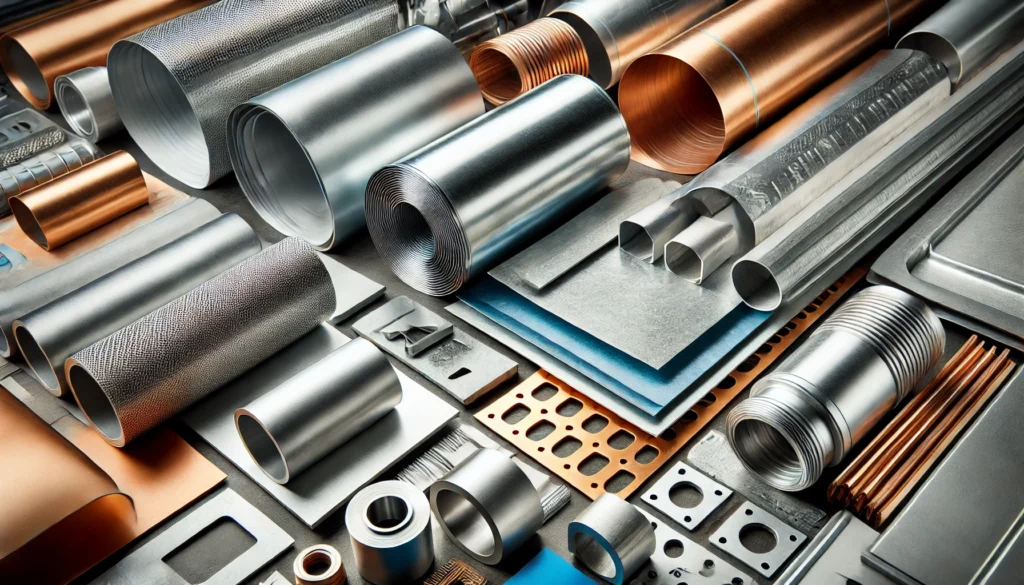

Material Selection

Selecting the Right Material

The first step in HVAC sheet metal fabrication is selecting the right material. The material you choose will determine the efficiency, lifespan, and cost of your HVAC system. Here are the most common materials you’ll use:

• Aluminum: Aluminum is lightweight, and it doesn’t rust. It’s easy to work with, and it’s used in many different HVAC components. Because it’s lightweight, it’s easy to install and puts less strain on the building. Also, because it doesn’t rust, it lasts a long time, even in harsh environments.

• Galvanized Steel: Galvanized steel is durable and inexpensive. It’s coated with a layer of zinc, which makes it rust-resistant. It’s great for any application where the metal will be exposed to moisture. The zinc coating prevents rust. Galvanized steel is also strong, so it’s good for structural components in HVAC systems.

Designing a Sheet Metal Component for Your HVAC System

Designing sheet metal components for your HVAC system is very important. It will affect the efficiency and lifespan of your system. Here’s what you need to do:

• Use CAD Software: First, you need to create detailed blueprints using Computer-Aided Design (CAD) software. This software allows you to make precise measurements and visualize your final product. This technology is crucial to ensure that every component fits perfectly within your HVAC system. This will make your system work better and be more efficient.

• Make Sure It’s Durable and Won’t Rust: You need to make sure that your sheet metal component is durable and won’t rust. This means you need to use the right material and design the component in a way that makes it resistant to rust. For example, you need to make sure it has proper ventilation and drainage so that water doesn’t sit on it. This is important to make sure it won’t rust.

• Get Expert Advice: You need to work with experts who can help you meet all of the specifications to make sure your HVAC system works the way you want it to. They can help you choose the right material, and they can help you design the component so that the gauge, thickness, shape, and size are perfect for your specific HVAC application. This is important because they can help you avoid common mistakes and make sure your product is high-quality.

If you design your sheet metal components correctly, they will make your HVAC system more efficient, improve airflow, and protect and stabilize your HVAC equipment. Working with experts in sheet metal fabrication can make a huge difference in the success of your HVAC system.

Cutting and Forming the Metal Sheet

The cutting and forming processes are vital to making accurate sheet metal parts that match the design you’ve created. There are various cutting techniques that are used to make the parts you need:

Cutting Techniques:

- Laser Cutting: Laser cutting is very accurate and gives you clean edges. It’s perfect for detailed designs. This method uses a focused beam of light to melt, burn, or vaporize the material, making a cut with minimal distortion.

- Plasma Cutting: Plasma cutting is used for thicker materials. It uses a jet of ionized gas at a high temperature to cut through the metal. This method is quick and efficient, making it great for heavy-duty work.

- Water Jet Cutting: Water jet cutting is done with no heat distortion and is precise for many different materials. It uses a high-pressure stream of water, often mixed with abrasive particles, to cut through metal. This method is used for materials that can’t handle high temperatures.

Once your part is cut, it’s time to shape it using tools and techniques like:

- Bending: Bending is done with a press brake to make accurate bends. This process involves putting the sheet metal on a die and pressing it with a punch to make the angle you want. It’s important to make sure the bends are accurate so the parts fit together.

- Rolling: Rolling is used to make round shapes for ducts. The sheet metal is passed through a series of rollers that make it into a round shape. This technique is used to make HVAC ducts and pipes.

- Stamping: Stamping is used to make complicated shapes that are the same every time. This process involves pushing the sheet metal into a die to make shapes like louvers, vents, or patterns. Stamping is used for large production runs because it’s fast and makes parts the same way every time.

- Drilling: Drilling is used to make holes and slots so you can put the parts together. You need to make holes for screws, bolts, or rivets that will hold the parts together. If you drill the holes accurately, it will be easy to put the parts together, and the final product will be strong.

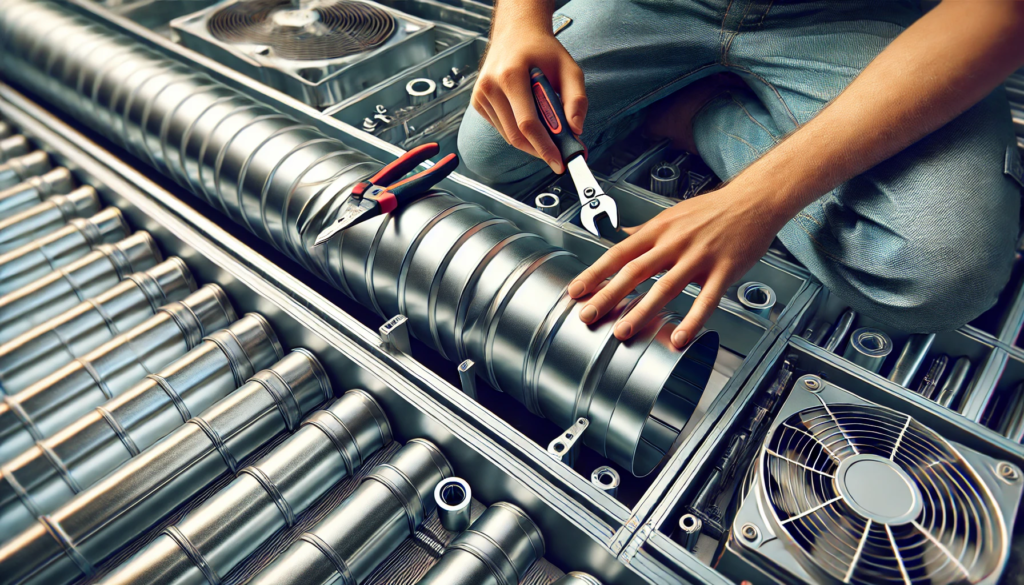

How to Assemble Sheet Metal Parts

Assembling the sheet metal parts you’ve cut and formed is an important step to make sure your HVAC system works the way you want it to. This process involves using different methods to join the parts together based on the needs of the parts you’ve made.

• Welding: Welding is one of the strongest ways to join sheet metal parts together. There are different welding methods used depending on what you’re working on:

- Seam Welding: Seam welding is when you weld a continuous seam along the edge of two pieces of metal, making a strong and airtight joint. This is good for parts that need to be airtight, like ducts.

- Tack Welding: Tack welding is when you make small welds at different spots along the seam to temporarily hold the pieces together. This is often done when you’re first putting the part together before you make the continuous weld.

- Stitch Welding: Stitch welding is when you make intermittent welds along the seam, making a strong joint while keeping the heat down. This is good for parts that don’t need a full seam weld but still need a strong joint.

• Riveting: Riveting is another good way to join sheet metal parts together, especially if you need to take the parts apart later. Rivets are fasteners that are put into holes you’ve drilled and then deformed to hold the parts together. This is good for parts that you might need to take apart later to fix or maintain.

• Screws and Bolts: Screws and bolts are used to join sheet metal parts that you need to put together and take apart often. This makes a strong joint that you can easily undo if you need to. This is good for securing panels and covers that you might need to take off often to check or fix something.

Surface Treatment

Finishing the sheet metal parts you’ve made is important to make your HVAC system last and look good. There are different ways to finish your parts, depending on what you need:

• Powder Coating: Powder coating is when you put a dry powder on the metal surface. You then heat the part to make a hard, durable finish. This is a good way to protect your parts and make them look good. Powder coating comes in many different colors and textures. It’s hard to chip, scratch, or fade, so it’s a good choice for your HVAC parts that will be in tough conditions.

• Plating: Plating is when you put a thin layer of metal on the surface of the sheet metal parts to make them last longer. There are a few common plating options:

- Zinc Plating: Zinc plating is good for protecting your parts from rust, especially if they will be in a humid place.

- Anodizing: Anodizing is used for aluminum parts. It makes the natural layer on the surface thicker, which makes the part last longer and helps it resist rust.

• Painting: Painting your parts makes them look good and last longer. Good paint can protect your parts from UV rays, keep the color from fading, and make the parts smooth. This makes your HVAC system look better and last longer.

Sealing and Finishing for Perfect Construction

It’s important to seal and finish your HVAC systems to make sure they work right, look right, and are strong. There are a few key things you need to do:

• Choose the Right Materials and Techniques: You need to pick the right things to seal and finish your HVAC system based on where it’s going to be, what it’s going to be exposed to, and how you want it to look. For example, if you’re putting it outside, you need to use weatherproof sealants to keep water out and prevent it from rusting.

• Pay Attention to Detail and Do Good Work: If you want your system to work and look right, you need to pay attention to the little things and make sure you do a good job all the way through the process. You need to pick the right stuff, put it on the right way, and make sure everything is perfect. This is how you make sure your HVAC system works right and lasts a long time.

• Get Help from People Who Know What They’re Doing: If you want to make sure your HVAC system is perfect, you need to work with people who know what they’re doing when it comes to sheet metal fabrication. These experts have the knowledge and skills to make sure your HVAC parts are made perfectly and work the way you need them to. They can tell you about problems before they happen and make sure your parts are perfect.

Installation & Maintenance Tips for Your HVAC System

You need to install and maintain your HVAC system right to make sure it works right. Here’s what you need to do to keep your system running its best:

• Custom Ductwork and Fittings: You need to make sure that the ducts and fittings you have are made for your system. This will help the air move better and keep you from wasting energy. When your ducts fit right, you won’t have leaks, which can make your system work better.

• Do Regular Maintenance: You need to do things like change your filter, clean your coils, and put oil on things to keep your HVAC system working right.

- Change the Filter: You need to change your filter every 1-3 months to keep dirt and debris from getting in the way and keeping your system from working right.

- Clean the Coils: You need to clean your coils once a year to make sure they work right and to keep dirt and debris from building up.

- Put Oil on Things: You need to put oil on things that move to keep them from rubbing together and wearing out. This will make your system last longer.

• Get an Annual Tune-Up: You need to have a certified pro come and look at your system once a year to keep it working right and to make it last longer. They’ll look at everything, clean some things, check for problems, and make sure everything is working right.

The Benefits & Drawbacks of Using Sheet Metal for Your HVAC System

When you’re putting an HVAC system in a big building, a lot of people use sheet metal ductwork because it’s good for some things and not so good for others.

Benefits:

• Lasts a Long Time: Sheet metal ductwork is strong and doesn’t burn. It can handle high temperatures and tough conditions, which makes it good for places that are tough on things.

• You Can Make It How You Want: You can make sheet metal ductwork that fits what you need for your HVAC system, which makes it work better. You can make ductwork that fits where it needs to go and makes the air flow right.

• You Can Make a Lot at Once: You can make a lot of sheet metal ductwork fast and cheap. This makes it good for big jobs because you can make a lot of things that are the same without losing quality.

Draback:

• It’s Heavy: Sheet metal ductwork is heavy, which makes it harder to install and takes longer. The weight can also make the building have more weight on it, which might mean you need more support.

• You Need to Keep It Clean: Over time, sheet metal collects dust and dirt, which can make the air bad. You need to clean it a lot to keep it working right and to keep the air in your building good.

If you want to use sheet metal for your HVAC system, you need to think about what you need and what your building is like. You need to think about how long you want it to last, how you want it to fit, how much it costs, how heavy it is, and how much work it is to keep clean.

Sheet Metal Fabrication at Premium

When it comes to building air conditioners and refrigeration systems, you need high-quality HVAC sheet metal fabrication. It’s not always easy, material is expensive, and it takes a lot of time. However, when you do it right, you save money, improve energy efficiency, and help the environment. When you work with experienced fabricators like Premium Mold & Mold, you get the best HVAC components you need to make your air conditioner or refrigeration system work right.

Conclusion

When you build air conditioners and refrigeration systems, you need high-quality HVAC sheet metal fabrication. It’s not always easy, material is expensive, and it takes a lot of time. However, when you do it right, you save money, improve energy efficiency, and help the environment. When you work with experienced fabricators like Premium Mold & Mold, you get the best HVAC components you need to make your air conditioner or refrigeration system work right.