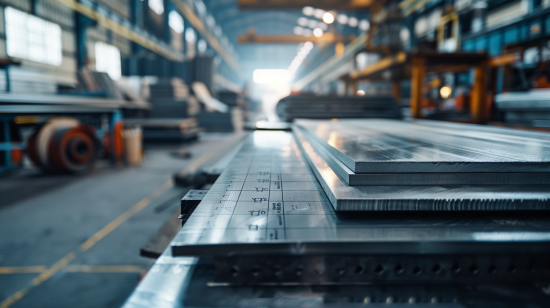

Selecting the right gauge of sheet metal is critical to making sure your project turns out strong, durable, and functional. But understanding what gauge means and how thick sheet metal is can be confusing.

In this guide, I’ll help you understand sheet metal gauges and give you practical tips and insights to help you decide what you need.

Sheet metal gauge is a term that describes the thickness of sheet metal, with a lower gauge indicating thicker metal. It is important to select the right gauge of sheet metal to get the strength and performance you need in applications ranging from automotive and aerospace to construction and consumer products.

When choosing the right sheet metal gauge, you need to consider factors such as the type of material, the application, and the strength you need. For example, heavy-duty applications often use thicker gauges because they need the strength, while lighter, more intricate work can use a thinner gauge. I’ll cover the basics of sheet metal gauges, how to read gauge charts, how to choose the right gauge for your project, and some of the challenges that come with different gauges.

What is Sheet Metal Gauge?

Sheet metal gauge is a standard measurement of sheet metal thickness. The gauge scale is inverse, meaning that a higher gauge number represents thinner metal. The gauge system originated in the 19th century when wire manufacturers needed a standardized way to describe wire thickness. Later, this system was adapted for sheet metal.

Understanding the gauge scale is essential for choosing the appropriate material thickness. For example, 12-gauge steel is much thicker and stronger than 22-gauge steel, which makes it suitable for structural applications. Conversely, thinner gauges are suitable for decorative or detailed work where precision is more important than strength.

Gauge Thickness vs Measured Thickness

While gauge numbers provide a general idea of sheet metal thickness, you need to know the difference between gauge thickness and measured thickness. Gauge thickness is a nominal value that represents the expected thickness of the material. Measured thickness is the actual thickness you get when you measure the material with tools like micrometers or calipers. Because of the way sheet metal is made, thickness can vary, so always measure the thickness to make sure it meets your specifications.

Types of Sheet Metal Gauge Charts

There are different types of gauge charts used for various metals, such as:

- Standard Gauge Chart: Commonly used for ferrous and non-ferrous metals, providing thickness measurements in inches and millimeters.

- Brown & Sharpe Gauge: Specifically for non-ferrous metals like brass and copper.

- Manufacturers’ Standard Gauge: Used for stainless steel and other specialty metals.

Using the correct chart for your material ensures accurate thickness measurements and appropriate gauge selection.

| Gauge Chart Type | Applicable Metals | Measurement Units |

| Standard Gauge Chart | Ferrous and non-ferrous metals | Inches, millimeters |

| Brown & Sharpe Gauge | Non-ferrous metals (e.g., brass, copper) | Inches, millimeters |

| Manufacturers’ Standard Gauge | Stainless steel, specialty metals | Inches, millimeters |

Common Sheet Metal Gauges and Their Uses

Different industries use different sheet metal gauges based on their requirements. Here are some common gauges and where they are often used:

• 22-gauge: Used a lot in automotive and HVAC because it is strong but still flexible.

• 18-gauge: Used in construction for roofing and siding because it is strong but not too heavy.

• 14-gauge: Used in industrial applications like equipment and machinery where you need something durable.

• 12-gauge and below: Used in heavy applications like structural components and high-stress environments.

Knowing what these gauges are used for can help you choose the right thickness for your project so it performs well and lasts a long time.

How to Read Gauge Conversion Charts

Gauge conversion charts are important for turning gauge numbers into actual thickness measurements. These charts show the thickness in inches and millimeters, making it easy to compare and choose. Here is how you read a gauge conversion chart:

- Find the gauge number: Find the gauge number you want on the chart.

- Convert to thickness: Find the thickness in inches or millimeters next to the gauge number.

- Compare materials: Use the chart to compare different materials because some metals will have different thicknesses for the same gauge number.

When you know how to use gauge conversion charts, you can make sure you know how thick something is and make the right decision for your project.

Sheet Metal Gauge: 4 Tips for Choosing the Right One for Your Project

- Understand What You Need It For: Figure out how strong you need the metal to be, how flexible it needs to be, and how heavy it can be. For example, if you are making a structural part, use a thicker gauge. If you are making something detailed, use a thinner gauge.

- Know Your Metal: Different metals have different properties. Aluminum is lightweight and doesn’t rust, so it is good for aerospace. Steel is strong and lasts a long time, so it is great for construction.

- Know Your Budget: Thicker gauges and certain metals cost more. Make sure you know what you need and how much you can spend.

- Ask Someone Who Knows: If you aren’t sure, talk to people who work with metal every day. They can help you figure out what you need and what you should buy based on what you are doing.

Practical Applications of Different Gauges

Different gauges are used for different things in different industries. Here are some examples:

• Cars: They use thin gauges (like 22-gauge) for body panels to save weight and make the car get better gas mileage. They use thick gauges (like 14-gauge) for the frame to make sure you are safe.

• Airplanes: They use lightweight stuff like aluminum in thin gauges (like 18-gauge) to make sure the plane is light but still strong.

• Houses: They use medium gauges (like 18-gauge) for the roof and the sides of the house because they are strong and easy to work with.

This shows how different gauges are used for different things so that you get the best performance and save the most money.

How to Measure Sheet Metal Thickness

You need to know how thick your sheet metal is to make sure you get the right thickness for your project. Here are tools you can use to measure sheet metal thickness:

• Micrometer: This tool clamps onto the sheet metal to give you a precise thickness measurement.

• Caliper: You put the sheet metal between the jaws of this tool to get a thickness measurement.

• Gauge tools: These tools are made to measure sheet metal thickness by comparing it to slots or openings that have been set to certain thicknesses.

When you use these tools, you can measure sheet metal thickness to make sure you get what you need.

Problems and Solutions

There are some problems you might run into when you are working with different sheet metal thicknesses:

• Dealing with thin metal: When you work with thin metal, it can warp and bend. Make sure you support it correctly and handle it the right way so it doesn’t get bent out of shape.

• Getting the same thickness: It can be hard to get the same thickness across many sheets of metal. Use good tools to cut and measure so everything is the same.

• Not damaging the metal: Thin metal can get scratched or dented easily. Handle it carefully and think about using a coating to keep it safe.

When you know about these problems, you can make sure your sheet metal project works well and lasts a long time.

Gauge Tolerances

Gauge tolerances are the acceptable variations in thickness within the same gauge. These tolerances can affect how well your sheet metal parts work together, so you need to know about them when you design and make parts. When you understand and manage these tolerances, you get the same results every time you make something.

How Different Materials Affect Gauge

Different materials of the same gauge can have different properties, like how strong they are, how flexible they are, and how much they weigh. For example, a 16-gauge sheet of aluminum will weigh less and not rust like a 16-gauge sheet of steel, but it might not be as strong. You need to know about these differences so you pick the right material and gauge for what you are doing.

FAQ

Q: What is the difference between sheet metal gauge and measured thickness?

A: Gauge is a nominal value indicating thickness, while measured thickness is the actual thickness obtained using measuring tools. Always verify the measured thickness to meet specifications.

Q: How do I select the right gauge for my project?

A: Consider application requirements, material properties, cost, and consult experts for guidance based on your specific needs.

Q: What tools are used to measure sheet metal thickness?

A: Common tools include micrometers, calipers, and gauge tools designed to measure thickness accurately.

Q: What are the common types of gauge charts?

A: Standard Gauge Chart, Brown & Sharpe Gauge, and Manufacturers’ Standard Gauge, each suited for different types of metals.

Q: How do gauge tolerances affect my project?

A: Gauge tolerances can impact the consistency and compatibility of parts. Understanding these tolerances helps in achieving reliable and precise fabrication results.

Q: Why do different materials with the same gauge have different properties?

A: Material properties like strength, weight, and flexibility vary between different metals, even at the same gauge. This affects their suitability for different applications.

Conclusion

Knowing about sheet metal gauges is important so you can get the right thickness for what you are doing. When you understand gauge numbers, conversion charts, and what people use different gauges for, you can make better decisions about the metal you use and how you use it. Use the information and tips in this guide to help you know more about sheet metal gauges and be more confident when you work with metal.