Choosing the wrong sheet metal supplier can lead to disaster. We’re talking defective parts, delayed timelines, and extra costs you never saw coming. You don’t want that, do you? The frustration of missed deadlines and scrapped projects is enough to make anyone want to throw in the towel. But don’t worry, I’ve got you covered.

It’s a maze out there, with suppliers offering a dizzying array of promises. How do you know who’s worth your time and investment? Do you feel trapped between choosing quality and budget, afraid that picking one will sabotage the other?

Let’s clear this up once and for all.

To get the best bang for your buck in sheet metal supplier selection, you must focus on the right mix of material choices, expertise, quality control, and manufacturing flexibility. This ensures high-quality products, smooth operations, and budget-conscious decisions—every time.

Now, let’s dig into how you can balance cost and quality while avoiding the supplier selection pitfalls that plague so many companies.

1. Understand Material Options and Their Costs

The materials you choose can make or break your project in terms of cost and performance. Some suppliers only offer a few materials, like aluminum or stainless steel. But what if you need to use galvanized steel for corrosion resistance? A good supplier will give you options and help you choose the best material for your project.

For instance, aluminum is chosen for its light weight and corrosion resistance, but it may not be strong enough for your application. Stainless steel may provide the strength you need, but it’s more expensive. You need to find the balance between performance and cost.

But here’s the key: Are you working with a supplier who is guiding you toward the most cost-effective material for your project?

2. Evaluate Supplier Process Expertise

Not all suppliers are the same. Many have state-of-the-art equipment, but they don’t have the expertise to back it up. Process expertise is critical, and I’m not just talking about cutting and bending metal.

The best supplier has technical engineers with years of experience. They can catch design mistakes early to prevent costly production errors. It’s not just about avoiding mistakes; it’s about making sure your design is optimized for manufacturability.

If your supplier can’t cut, bend, laser, and weld metal with precision, you’re in trouble. Remember: A supplier who understands the process can save you time, money, and headaches.

3. Demand Consistency with Surface Treatment

Let’s say you have a part that requires powder coating. Now, imagine you have thousands of units needing the same treatment. If the first batch comes out looking flawless, but the second batch looks like it was treated with a different process, what do you do? Return it? Complain?

Inconsistent surface treatments are a nightmare. Powder coating, anodizing, or any other finishing process needs to be perfectly repeatable. You can’t risk a supplier that delivers inconsistent finishes across batches. Consistency ensures that the parts fit perfectly in your assembly lines and present well to your clients.

Does your supplier have a track record of delivering consistently finished products across multiple orders?

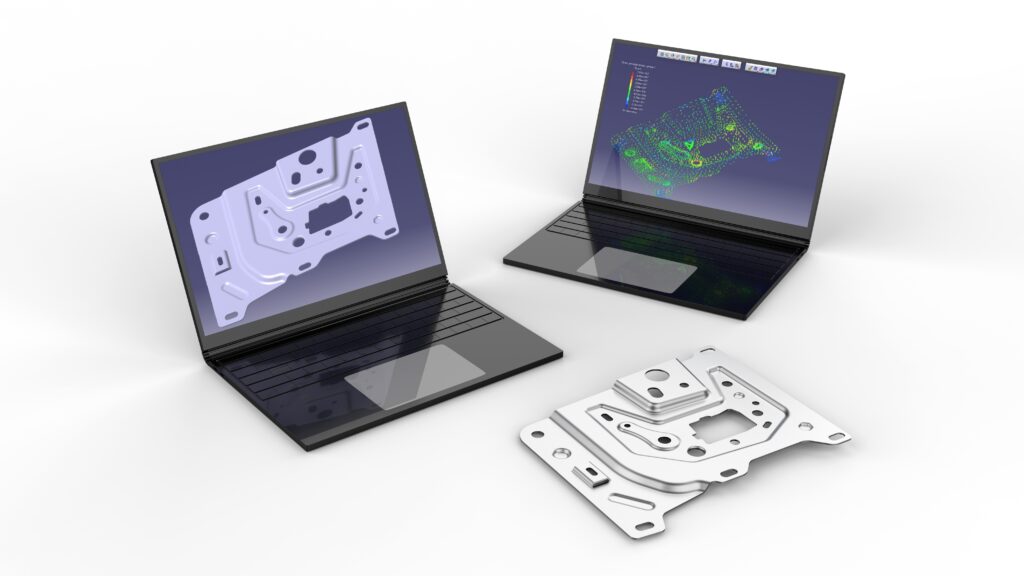

4. Use Design for Manufacturability (DFM)

Here’s where things get interesting. The best suppliers don’t just build what you design; they collaborate with you to make your designs even better. This is the beauty of Design for Manufacturability (DFM). They help you tweak your design so it’s not only easier to produce but also cheaper—without sacrificing quality.

We’ve all seen designs that look perfect on paper but fail in production. A knowledgeable supplier will help refine your drawings by suggesting alternative materials or geometries that reduce complexity, which in turn reduces cost.

Are you partnering with a supplier that actively engages in your design process, offering suggestions that save you money and improve manufacturability?

5. Focus on Packaging and Logistics

Once they’re made, how they get to you matters. If they’re poorly packaged, they’ll get damaged, and you’ll pay for it. And it’s not only about damage. It’s also about the cost of shipping.

A good supplier understands that space costs money. They’ll use space-saving packaging that protects the parts while lowering your freight costs. They don’t throw the parts in a box as an afterthought. They make sure the parts get to you safe and on time.

Does your supplier take shipping seriously, or does it cost you money and make you mad?

6. Make sure they do prototyping and testing

Before you start making a million of something, you need to know your design works. That’s where prototyping comes in. Not every supplier can prototype, test, and validate in-house.

Choose a supplier who can support small-batch production and sample validation. That way, you can make quick adjustments and perfect your product before you make a million of them. Trust me, it’s better to find out you have a problem with a prototype than to find out you have a problem when you have a thousand of them.

Are you sure your supplier can scale your production efficiently after successful prototyping and testing?

7. Make sure they do quality control and after-sales support.

One of the worst things you can do is to ignore quality audits. Many suppliers skip this step or don’t take it seriously, and that’s a mistake. You want a partner who does detailed quality checks throughout the entire production process. That way, you catch defects early and don’t have to pay for rework or wait for delivery.

But that’s not all. After-sales support is just as important. If a supplier doesn’t fix quality problems quickly, you’re stuck with a pile of junk. Make sure your supplier is responsive and has a good track record of fixing problems quickly.

Is your supplier actively auditing quality, or do you find out about defects after you receive the parts?

8. Check Supplier’s Production Scalability

You might start with a small batch today, but what happens when you need to make more? Can your supplier handle it without sacrificing quality or making you wait forever? The answer will determine whether you have a smooth road ahead or a series of problems that slow you down and make you mad.

Suppliers who can scale production don’t just make a lot of parts fast; they keep the same level of quality when you order a lot. This is important as you grow and need to make more parts.

Is your supplier set up to grow with you, or will they lose control of quality and deadlines when you need more parts?

9. Consider Cost-Effective Joining Methods

Welding is one of the most common ways to join parts in sheet metal fabrication, but it’s not always the cheapest. In some cases, riveting or hardware insertion can provide the same strength at a fraction of the cost.

If your supplier is good, they should be able to help you find less expensive ways to do this. The goal is to save money without sacrificing quality, and understanding how parts are joined can help you do that.

Are you looking for ways to save money on your parts, or are you using expensive methods because they’re what you know?

Conclusion

In the end, choosing the right sheet metal supplier is all about balancing cost and quality. By following these 9 tips, you’ll avoid common problems and make sure you get what you need from design to delivery. You don’t have to spend a fortune to get quality parts if you have the right partner.

Take your time when you’re looking for a supplier, and you’ll save money, time, and a lot of headaches.